Orca Ocean Show

General information

-

Location address

Puerto de la Cruz, Tenerife Island

-

Location country

Spain

-

Name of the client/building owner

Loro Parque S.A.

-

Function of building

Stadia

-

Degree of enclosure

Open structure

-

Climatic zone

Mediterranean - mild winters, dry hot summers

-

Number of layers

mono-layer

-

Type of application of the membrane

covering

-

Primary function of the tensile structure

- Rain protection

- Sun protection

Description

Introduction

Loro Parque is one of the biggest tourist attractions of the Canary Islands. They had the ambitious idea to show the first orca spectacle in Spain. For that purpose Loro Parque desired to have an impressive exhibition site, in accordance with the importance of the show.

In this way, Loro Parque asked for a roof design to cover the orcas’ swimming exhibition pools. Comercial Marítima, as Contractor, and Arenas & Asociados, as Design Engineers, submitted the winning design.

The design criteria specified by Loro Parque were fully met by Comercial Marítima and Arenas & Asociados’ design. Loro Parque asked for a roof, comfortable for the spectators - protecting them from rain, wind and excessive sun - and functional for the orcas - meaning that the roof was not a barrier in case the orcas had to be evacuated for medical reasons. The roof design pleased the owners, not only because it satisfied their requirements, but it gave a fantastic view to the ocean horizon.

It is important to add that the design of the roof was restrained by the fact that the foundations and the stands had already been designed. But this was not an obstacle for reaching a good design!

Steel structure

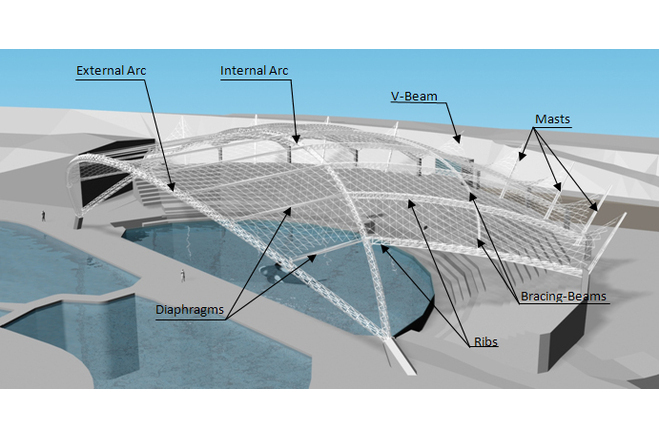

The supporting structure for the tensile members is built in steel, except the foundation, obviously built in concrete. The elements that constitute the steel structure are: two main arches, ten diaphragms between them, ten ribs with its supports avoiding buckling in the arches, eight masts and a V-beam, and the slender beams that brace the ribs.

Arches

The pair of arches, with concrete abutments, span 64m with a sag of 16m, which means a sag/span ratio of 1/4. At the highest points the maximum transversal span between the arches is materialized, being a distance of 22m. The arches have been designed as a parabolic curve, which is an approximation for the reversed funicular shape. Both arches, internal and external have a hollow box section with a height of 600mm and a width of 700mm, with a thickness of 10mm and 12mm respectively. The shape of the arches is very interesting because the external faces show a singular play of light and shadows while the internal face is plane to simplify the steel connections. The slender diaphragms, with a square section of 200mm, have been arranged between the arches to avoid the buckling of the arches and to support the compressive strength due to the tensioning of the tensile membrane.

Thanks to the lightness of the arches they could be built by means of a crane and auxiliary steel towers acting as a temporary support.

Ribs

Another interesting part of the structural frame that supports the tensile membranes are the ribs. They have a parabolic semi arc curve, they span between 21m and 32m and brace laterally the most stressed arch, being the inner arch. The ribs avoid fundamentally the lateral buckling of the arch, and in a minor way, the buckling in its own plane, due to the flexural stiffness of the ribs. The buckling safety is not the dimensioning criterion for the arch. The external arch is braced to the inner one thanks to the diaphragms, although the external arch is less stressed than the inner one.

The ribs have a hollow box shape, with the upper flanges adjusted to the curvature of the textile which is attached to the ribs. These ribs have a width of 200mm and a height of about 600mm, with several sheet thicknesses depending on the span.

The boundary ribs are very important, because they have to carry the unbalanced forces due to the stand membrane. That is the reason for introducing the bracing beams among the ribs. These bracing beams increase the safety factor of the ribs against lateral buckling.

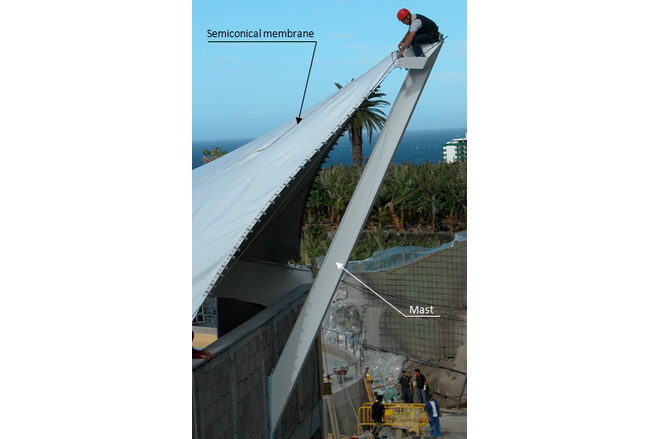

Mast

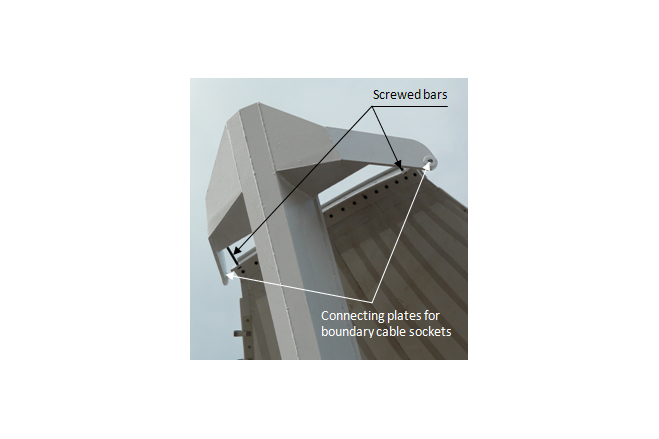

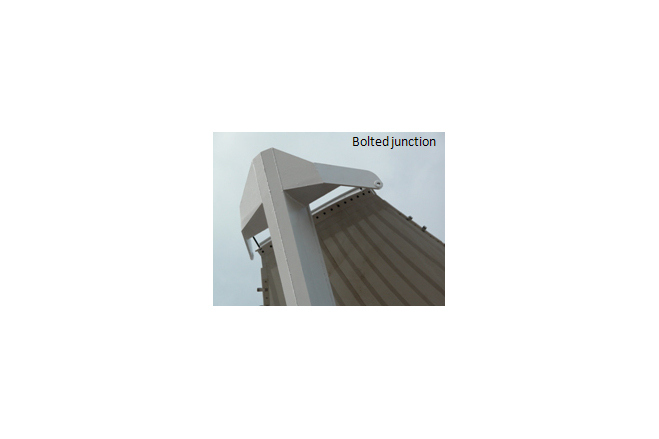

The steel frame is completed with the masts, being a fixing point for the semi conical membranes. In the crown of the mast a connection system for the textile membrane with screwed bars was designed. These bars make it possible to adjust the tension in the membrane. The masts are 8m high and have a variable cross section, with convex flanges and concave webs having a maximum width and height of 250mm and 500mm respectively, at the fixing to the concrete frames of the stands.

Foundation for the main arches

Finally, the membrane supporting structure is completed by the foundation of the arches, consisting of a surface foundation of 5m width, 8m length and 1.3m depth and a wall of concrete of 8.60m height placed on the footing.

This solution was needed due to the presence of a service gallery between the exhibition pool and the training and medical pools. The level of the gallery was 8.60m below the surface, being the reason for having used a concrete wall for the foundation of the arches.

Arising from the surface level, a prismatic concrete piece was designed having a full formal coherence with the section at the junction of the arches.

As conclusion, we can say that this concrete basement makes that the union between the inner and external arch takes place 2.23m above ground level, permitting a suitable free vertical span for pedestrian flows, the piece having a human scale indeed.

Tensile structure

The tensile structure made with polyester PVC coated membrane Fluotop 1302 by Ferrari is the principal material of the roof. It has two differentiated parts. One part covers the Stand and the other covers the Exhibition pool. Both membranes were tensioned from the boundaries by means of tractels.

The Stand Membrane

The Stand Membrane protects the spectators from the environmental hazards, like sun, rain and wind. This membrane is anticlastic, organized in a succession of ridges and valleys, with nine semi conical shaped membranes in the backstage of the Stand.

This membrane is subdivided in nine modules, each module being situated between two ribs of the steel frame. The modules are connected to the steel structure by means of spectra strands fixed to reeds at the ribs, clamps at the inner arch and bolts at the masts.

All junction details were meticulously studied to avoid the filtering through of rain water in the exhibition pool, because this could infect the Orcas.

In order to avoid the introduction of unbalanced forces in the ribs, the tensioning of the Stand membranes was carried out in several phases and coordinated with the tensioning of the nearest modules.

The textile Stand membrane was not only studied in a structural way. Throughout the design process we were always looking for the best aesthetical impression of the membrane covering, even when thinking on the details, like the seams for patterning.

The conical shaped part of each Stand membrane module improves the structural response against external and internal loads due to its double anticlastic curvature in both ways, reducing the stresses in the membranes and the deformations of such membranes.

The Exhibition Pool Membrane

The Exhibition Pool Membrane is the most attractive, from our point of view, part of the roof. We understand this membrane in conjunction with the arches, give fantastic sights to spectators.

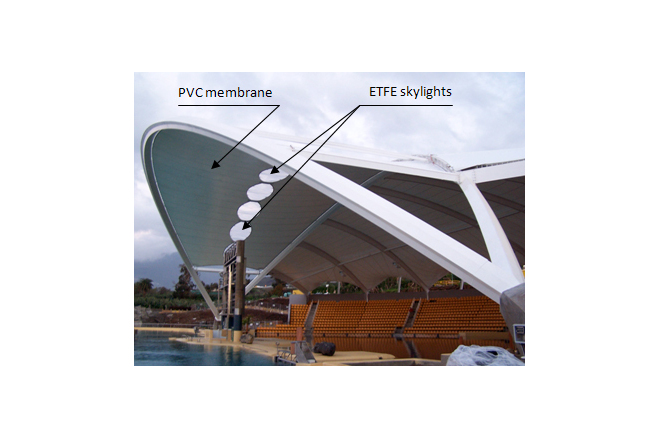

Covering 1600m2, this membrane introduces an innovation in membranes and it is the conjunction of PVC and ETFE membranes. The introduction of a central band of skylights made of ETFE single layer creates an interesting play of light and shadows over the exhibition pool.

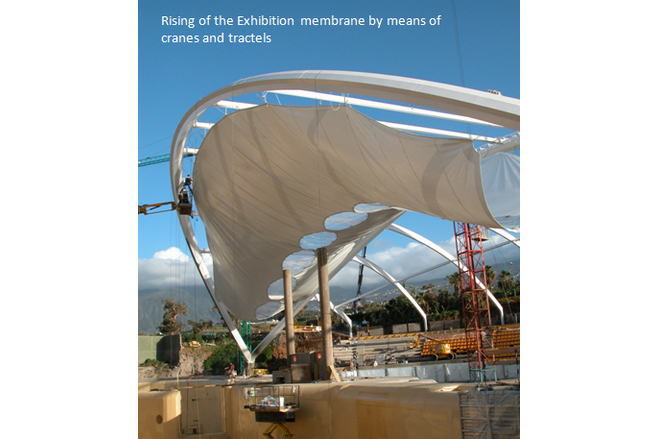

The membrane was built in one piece at the Comercial Marítima L&Z Factory. As it was done in the Stand membrane modules, the seams order was identically studied to reach the impressive sight that spectators can receive from their seats in the stand. Once the Exhibition Pool membrane was manufactured it was delivered by ship from Vigo to Tenerife, and then raised by means of cranes to its position between the steel arches. The lightness of the membrane permitted to build the entire exhibition roof in one time.

If another material would have been used, the construction phases would have increased with it’s consequently delay in time. Construction time was a premise imposed by the Property, Loro Parque, and one of the reasons of choosing a membrane roof was precisely the fastness that the building of a membrane solution could provide.

The rising of the membrane was made using first of all cranes and then tractels. The tractels achieve the slowest approximation to the arches, permitting to adjust the union with the arches in several phases. With this procedure the big membrane of 1600m2 could be installed with the desired geometry.

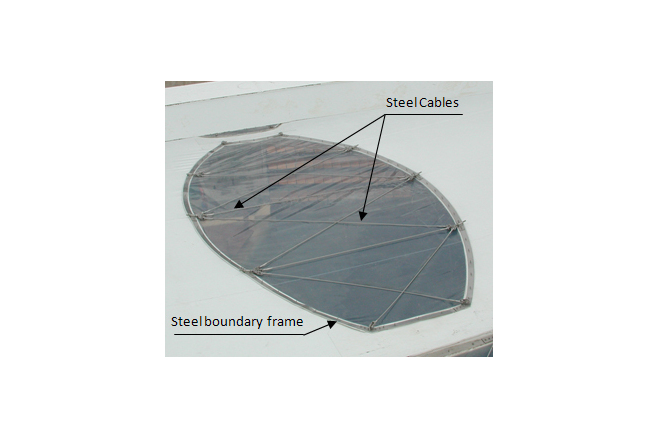

As it was told previously, one of the innovating and interesting aspects of the roof is the conjunction of PVC and ETFE membranes. The ETFE membrane, with a thickness of 200µm, has a different Young’s modulus from the polyester PVC coated membranes. For maintaining compatibility between the deformations of both materials, steel cables were introduced over the ETFE skylights. These cables were fixed to the connecting steel frame between the polyester PVC coated membrane and the ETFE foil.

But not only were the steel cables needed for achieving the high stress flow between the lateral sides of the membranes, it was necessary to reinforce the narrow corridors connecting both sides of the membrane.

Summarizing, the narrow corridors between the two sides of the membrane are high stress concentration points, solved by means of steel cables and membrane reinforcements.

The connection of the membrane to the steel arches was made using clamps, like it could be seen in the Stand membranes.

Conclusion

Comercial Marítima L&Z and Arenas & Asociados have projected and built an impressive roof that has fully satisfied the Property, Loro Parque, and that is enjoyed by the thousands of spectators visiting every day the Orca Ocean Show. A mixing of technology and beauty for an unequal environment and exceptional animals, like are Tenerife Island and the Orcas, respectively.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Material Fabric/Foil

PVDF Precontraint 1302T2

Main dimensions and form

-

Covered surface (m2)

6085

Duration of use

-

Temporary or permanent structure

Permanent

-

Convertible or mobile

Convertible

Involved companies

-

Architects

Arenas & Asociados

-

Engineers

Arenas & Asociados

-

Contractors

Comercial Marítima L&Z

-

Suppliers

SERGE FERRARI

Editor

-

Editor

Evi Corne