Landing Craft Tank: Tensile Fabric Canopy

General information

-

Home page

www.architen.com

-

Location address

Southend-on-Sea

-

Location country

United Kingdom

-

Year of construction

2020

-

Function of building

Historical buildings & monuments

-

Degree of enclosure

Open structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

mono-layer

-

Type of application of the membrane

covering

-

Primary function of the tensile structure

- Rain protection

Description

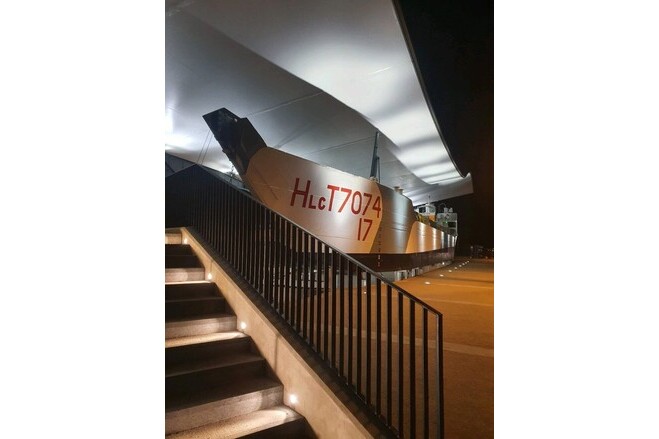

Tensile fabrics have long been associated with modes of transport, from sail boats to hot air balloons and even traditional caravan covers but it’s not every day that a tensile fabric structure is built to cover a landing craft tank.

Architen Landrell were approached by Pritchard Architecture on a nationally significant project to relocate the last remaining Landing Craft Tank (LCT) from the D-Day landings to Southsea, just outside the D-Day Museum. After the original singly ply roof with a timber soffit proved too expensive, the design team came to talk to us about designing a tensile fabric canopy to go over the ship, supported by a large, curved, cantilevered steel structure.

Key to the design intent was a slender, curved leading edge, flush white underside and grey top side and Architen worked with all the key stake holders including the National Museum of the Royal Navy and local authority to meet these design demands.

The desired clean lines were achieved by locating the tensile fabric membrane on the underside of the steelwork. This hid all of the structure above but posed a challenge for the drainage of rainwater. Our specialist tensile fabric design and engineering team developed a clever hopper detail around the posts to drain water effectively and ensure no leaks.

PVC coated polyester was an obvious choice due to the fact that it is available in a range of colours, offers a long lifespan, easy maintenance and also met the client’s tight budget. Further discussions determined that a blackout fabric would be preferable thus allowing the opportunity to project film or light on to the canopy in the future. Due to the strict planning restraints we had to find a black out fabric with white underside and a specific grey upper which led us to Sattler’s Polyplan Tent Manege 671 Dual Colour Type II.

Photographs courtesy of Peter Langdown

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Type (code)

Polyplan Tent Antiwickling

-

Material coating

PVC-coated polyester

Main dimensions and form

Duration of use

-

Temporary or permanent structure

Permanent

-

Design lifespan in years

21-30

Involved companies

-

Contractors

ARCHITEN LANDRELL

-

Suppliers

Sattler PRO-TEX GmbH

Editor

-

Editor

Amy Richardson