Saga Headquarters

General information

-

Home page

https://www.hopkins.co.uk/projects/workplace/saga-group-headquarters/

-

Location address

Sandgate, Kent

-

Location country

United Kingdom

-

Year of construction

1999

-

Name of the client/building owner

Saga Group Ltd.

-

Function of building

Multipurpose halls

-

Degree of enclosure

Hybrid structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Primary function of the tensile structure

- Daylight gains

- Rain protection

- Wind protection

Description

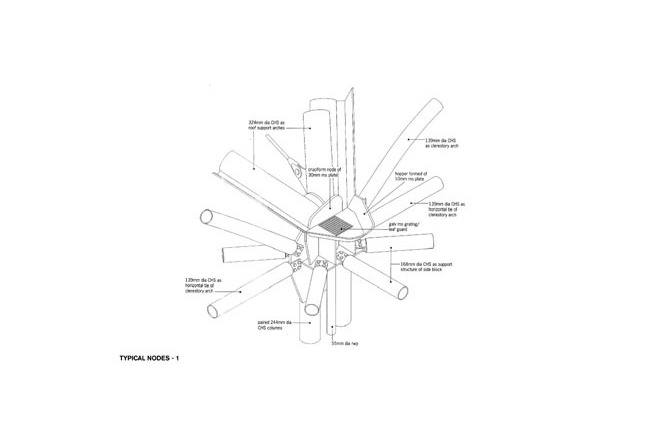

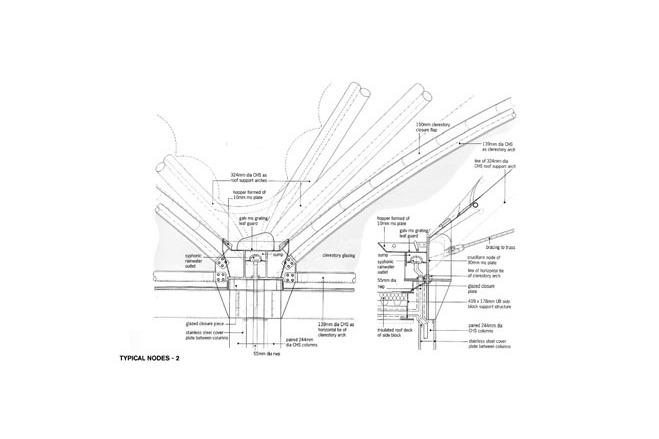

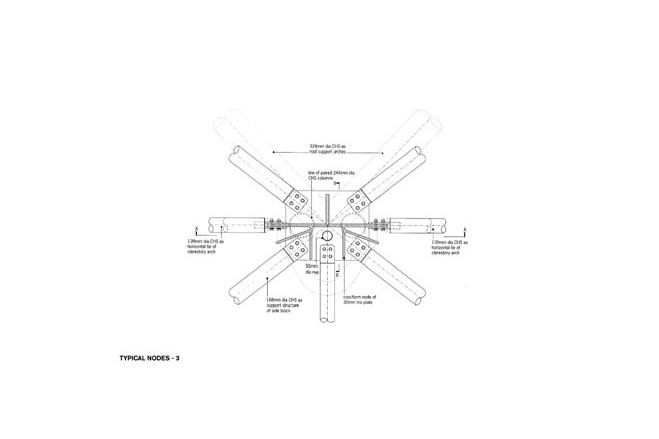

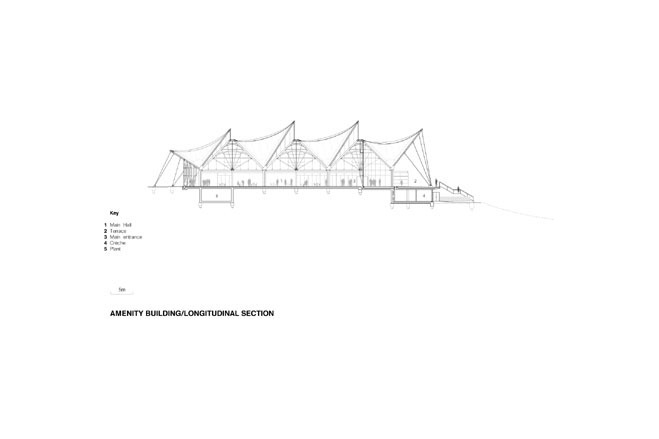

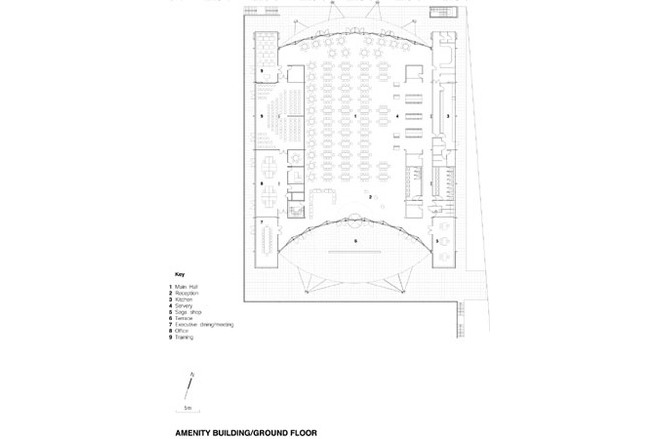

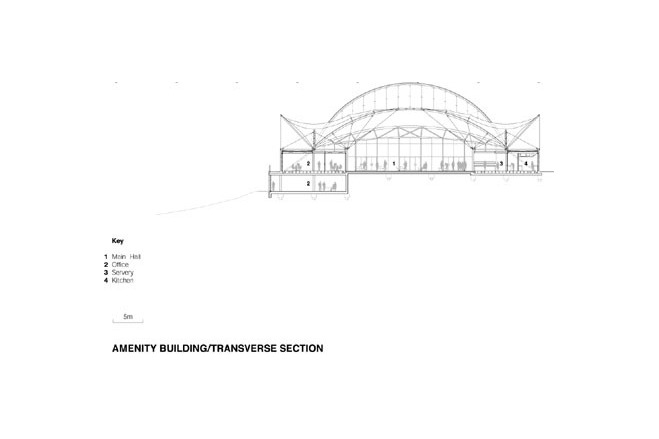

Office building & amenity building with canteen, meeting rooms & gymnasium. Amenity building has large PTFE/glass membrane panels tensioned between slender steel arches.

The Saga Group commissioned us to prepare a Masterplan for the phased development of their 28 acre steeply wooded seaside site at Sandgate near Folkestone for their new Group Headquarters.

The principal office buildings were designed to provide a naturally ventilated environment with low energy usage throughout its life. The main ground floor area is the workroom, accommodating the telesales area within a single large volume. The support offices are contained within the rear block which has five floors of office accommodation. The south elevation of the office building is constructed with a climate wall to give a buffer against the prevailing weather conditions and act as a conservatory space to the office proper.

The separate amenity building houses the training areas, a nursery, kitchen and restaurant areas as well as providing a large hall for private and public functions. The building consists of a large fabric covered central hall orientated towards the sea with side blocks of accommodation on the east and west elevations.

2012 - Saga is to close its Kent headquarters as a result of changes to working patterns following the pandemic.

Description of the environmental conditions

Low energy design as thermal mass keeps the offices comfortable & cuts fuel bills.

The 11ha wooded site, falling steeply from clifftop to sea, gives panoramic views over the Channel and has direct contact with the elemental forces of earth, air and water.

Winter

Electric infra-red radiant heaters mounted at high level above the side blocks provide an instantaneous ?top-up? of heat to meet demand on the coldest winter day.

Natural wind driven infiltration provides an adequate ventilation rate in winter.

Perimeter trench heating beneath the end wall glazing offsets some of the fabric losses in support of the underfloor heating.

Underfloor heating provides the base heating requirement, stabilises the internal environment, the cold radiant effect of the fabric roof.

Summer

The central hall is naturally ventilated in summer and mid season through large areas of openable doors and vents at very high level within the glazeline.

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Type (code)

B18059

-

Material Fabric/Foil

Glass

-

Material coating

PTFE

-

Weight (g/m2)

1450

Main dimensions and form

-

Covered surface (m2)

2000

-

Maximum height (m)

16

-

Total length (m)

57

-

Total width (m)

56

-

Form single element

Anticlastic

-

Form entire structure

Anticlastic

Duration of use

-

Temporary or permanent structure

Permanent

-

Design lifespan in years

21-30

Involved companies

-

Architects

Michael Hopkins & Partners

-

Engineers

Arup

-

Contractors

Koit High-Tex GmbH

-

Suppliers

Verseidag-Indutex GmbH

Editor

-

Editor

Marijke Mollaert