Mina Tent City Phases II and III

General information

-

Location address

Mina Valley, Makkah

-

Location country

Saudi arabia

-

Year of construction

2000

-

Name of the client/building owner

Ministry of public works and housing KSA

-

Function of building

Religion

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Arid - dry and hot all year

-

Number of layers

mono-layer

-

Primary function of the tensile structure

- Sun protection

Description

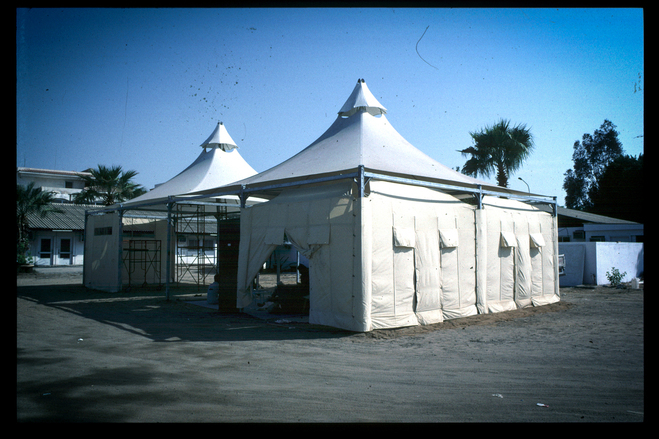

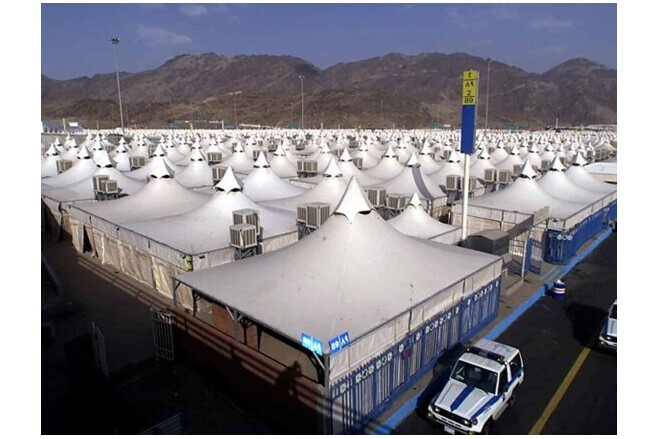

Tent city for two million pilgrims for the Hajj, built as non combustible Teflon coated glass fibre tents supported by a hot dip galvanized steel structure. The tent city is built of several types of tents, based on a 8x8 m standard tent module.

Amongst the most interesting of stressed textile projects in recent years has been the Mina valley project in Saudi Arabia. Every year two million followers of the Islamic faith make the Hajj pilgrimage to the holy city of Mecca. As part of the event these pilgrims travel to nearby mount Arafat, where they spend the night camping in the Mina valley. Following a series of fatal disasters culminating in a large fire in 1997, the Saudi government decided to replace the existing cotton structures with fireproof Teflon coated glass fibre tents.

Phase I of the project, which was carried out by Koch, SL and Tensys during 1997 and 1998, provided 25% of the planned 40 000 tents. Phases II and III were carried out by a different group with the membrane engineering provided by Technet GmbH. Over 30 300 tents covering approximately 1 875 000 m2 were built and installed during Phase II and III making this the world's largest lightweight structure project.

As with Phase I, the majority of the tents were constructed from six modular designs. These rectilinear structures ranged in size from 4x4m through 8x6m, 8x8m, 8x9m, 8x10m to 8x12m. They were patterned from four triangular fields. Unlike Phase I, the fields were fabricated from cloth strips with the textile weft parallel to the outer boundaries.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Material Fabric/Foil

Glass

-

Material coating

PTFE

Main dimensions and form

-

Covered surface (m2)

1875000

-

Form single element

Anticlastic

Duration of use

-

Temporary or permanent structure

Permanent

-

Design lifespan in years

11-20

Involved companies

-

Architects

SL Rasch GmbH

Werner Voss Architect Office

-

Engineers

technet GmbH

TTT

Tensys

-

Contractors

Obeikan Investment Group

-

Suppliers

Verseidag-Indutex GmbH

Editor

-

Editor

Marijke Mollaert