BERLIN'S OLYMPIC STADIUM

General information

-

Location address

Berlin

-

Location country

Germany

-

Year of construction

2004

-

Name of the client/building owner

City of Berlin

-

Function of building

Stadia

-

Degree of enclosure

Open structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Primary function of the tensile structure

- Daylight gains

- Rain protection

- Space defining elements

- Sun protection

- Wind protection

Description

Everything has been prepared for the final match in July 2005: the newly refurbished Olympic Stadium in Berlin, Germany, gives 74,000 spectators a clear, unobstructed view of the soccer field. The new lightweight roof construction, made of woven fiberglass membranes coated with Dyneon PTFE and Dyneon Fluorothermoplastics, ensures that everyone is protected from rain and other weather conditions.

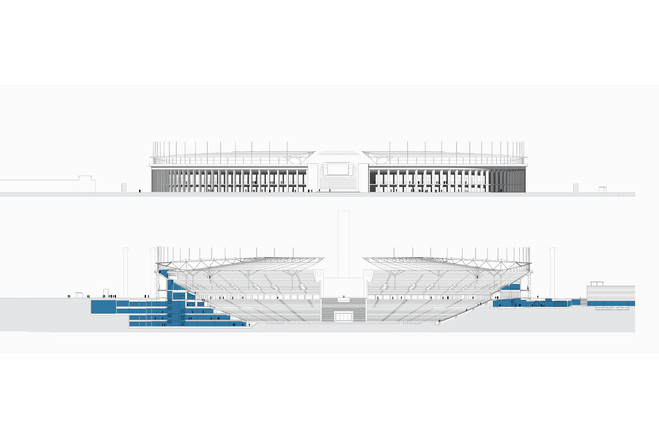

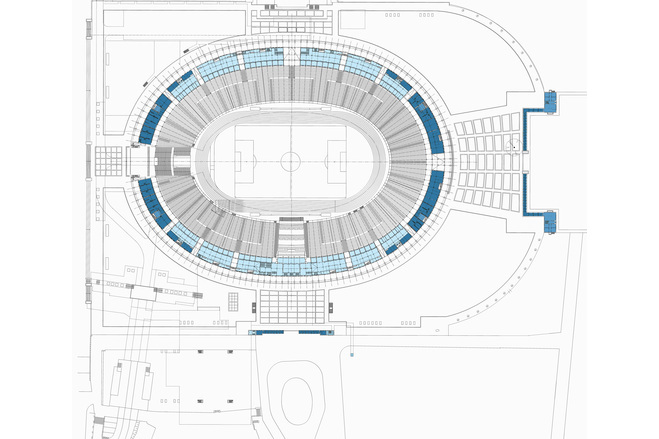

The conditions associated with the construction of the new roof of the Berlin Olympic Stadium were extremely challenging for the Berlin architects Gerkan, Marg and Partners: the entire structure of the roof was to stay within the boundaries of the ground plan of the existing stadium. Because it is classified as a historical monument, its original appearance was to remain as unaffected as possible. At the same time, the spectators? view of the playing field was to be as unobstructed by supporting structures and columns as possible. To make things even more complicated, all of the reconstruction work was to be accomplished without interrupting regular-season matches.

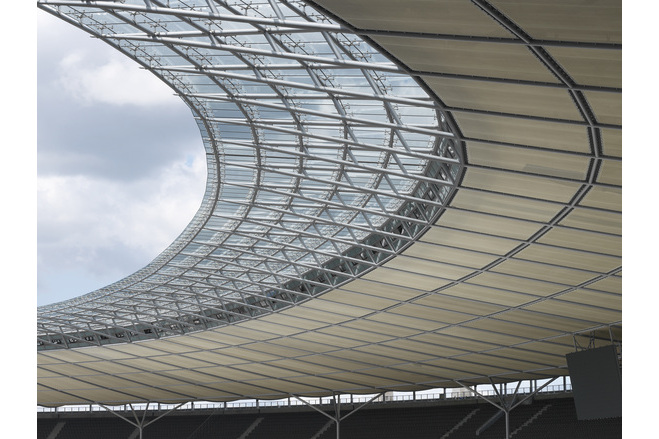

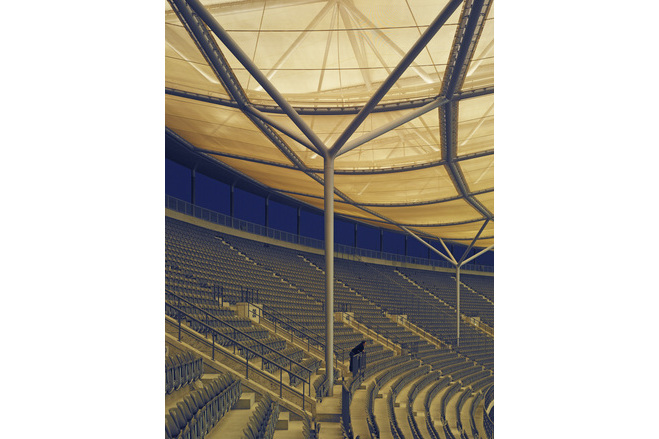

The architects decided on a lightweight cantilevered steel construction for the U-shaped roofing over the stands. It does not form a closed ring but remains open in the middle and in front of the historical Marathon Gate Arch, in order to preserve the view from the stadium seats to the Maifeld (May Field) and the Glockenturm (Bell Tower), all in line with the wishes of historical monument preservation. In the upper regions of the stands, 132 outer steel posts and 20 slender steel posts positioned in the stands, having a pedestal diameter of only 250 mm, are essentially all that is supporting the steel construction of the roof, which looks like it is floating over the stadium.

Hightex GmbH of Rimsting, Germany, a company that specializes in textile architecture, covered the outside surface of the supporting structure with 27,000 m² of woven fiberglass membrane in 77 membrane sectors. These membranes are made of coated woven fiberglass having a tensile strength of up to several tons per square meter, and they themselves weigh only one to one-and-a-half kilograms per square meter. The coating with Dyneon PTFE and Dyneon Fluorothermoplastics is what gives this material these all-important properties for heavy-duty use in architectural applications: the surface of the coating is very smooth and has a long-lasting resistance to varied weather conditions, which has been demonstrated in many years of use in very different climate zones. In addition, Dyneon PTFE possesses a nearly universal chemical resistance and exceptionally good mechanical properties.

A key advantage of PTFE coatings is that they require neither softeners nor stabilizers, which can evaporate over time and can cause the coatings to become brittle. The PTFE allows the membranes to remain elastic and smooth so that even after a number of years of service, dirt and contamination are unable to find cracks to settle into. Rain showers are typically all that is needed to clean the roof even after many years of use. The translucency of the woven material guarantees during daylight hours that the lighting conditions inside the stadium are ideal for both spectators and players.

Hightex GmbH also lined the lower side of the roof construction with a Dyneon PTFE coated, open-grid woven fiberglass matting. This lower side serves as maintenance gangways for the glare-free floodlight system installed under the roof, as well as for the sound system that has more than 150,000 watts of power. This installation technique eliminates the need for distracting masts around the borders of the playing field. The open-structured fabric of the lower side allows sound and light to pass through, while at the same time ensuring ideal pressure compensation through to the upper membranes under windy conditions, thus also helping to reduce the static load on the steel construction of the roof. Taken altogether, soccer fans visiting the Olympic Stadium will have a perfect view of the final match in July.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Material Fabric/Foil

Fiberglass

-

Material coating

PTFE

-

Weight (g/m2)

1500

Main dimensions and form

-

Covered surface (m2)

27000

-

Form single element

Anticlastic

-

Form entire structure

Flat appearance

Duration of use

-

Temporary or permanent structure

Permanent

Involved companies

-

Architects

Gerkan, Marg und Partner

-

Engineers

schlaich bergermann partner

-

Suppliers

Hightex GmbH

Editor

-

Editor

Marijke M. Mollaert