Chemical Research Centre in Venafro

General information

-

Location address

Venafro

-

Location country

Italy

-

Year of construction

1990

-

Name of the client/building owner

Guido Ghisolfi, Sinco Engineering S.P.A., Tartona

-

Function of building

Laboratories & research centres

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

mono-layer

Description

Design

Requirements

For over thirty years the M & G group has been working in the field of polymer research and polymer processing. In 1990 they decided to concentrate the different research activities at one location, at the enterprise M & G Ricerche SpS in Pozzilli in southern Italy, and at the same time to streamline their activities.

The centre consists of two areas: a technical area with pilot plants for the development of production and processing methods, and a chemical-physical area with labs for the synthesis and analysis of chemical products. The implementation of these chemical and physical largescale experiments has a varying space requirement which is predictable only with difficulty. From this fact resulted the requirement to create an open, column-free space as large as possible, which at the same time would allow for separate tests to be carried out in smaller protected units.

Concepts

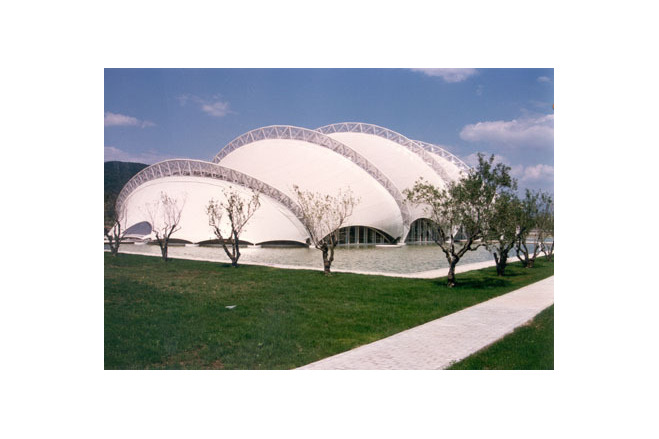

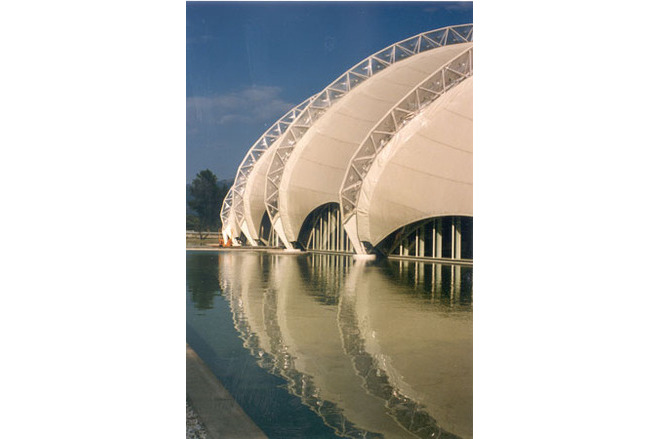

Considerations with regard to the optimal shape of the hall led to an elliptical plan; a lightweight, tent-like form appeared already on the first sketches and developed to an oval shape (85 x 32 m) as one large volume, covered by a lightweight structure with a height of 15 m, supported by symmetrical lattice arches and braced by six longitudinal stabilising cables. The outline of the service installations and the pilot plants led to the choice of the arch shape as a flat basket (three-centre) arch. The maximum height of the pilot plants and the apex height of the building compliment each other. The optimal span for the roof membrane lies between 12 m and 15 m and this determined the number of arches. Aspects like the bracing of the arches, the transfer of the membrane forces and the search for a balanced design caused the architects to arrange the arch planes so that they intersect at a point which at the same time is the centre of the circle connecting the apexes of the arches.

Functions

This space lit by the translucence of the roof membrane and through the glazed edge openings houses research areas. The spaces at the gable ends between the side membrane and research spaces serve as common rooms and reception areas for visitors. The floor space totals 2700m².

Structure

Arches

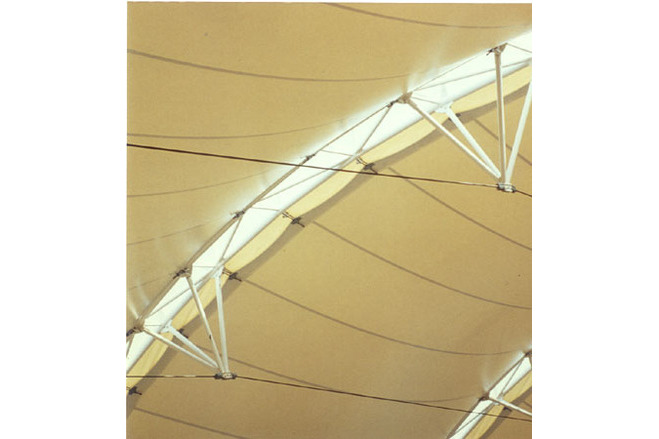

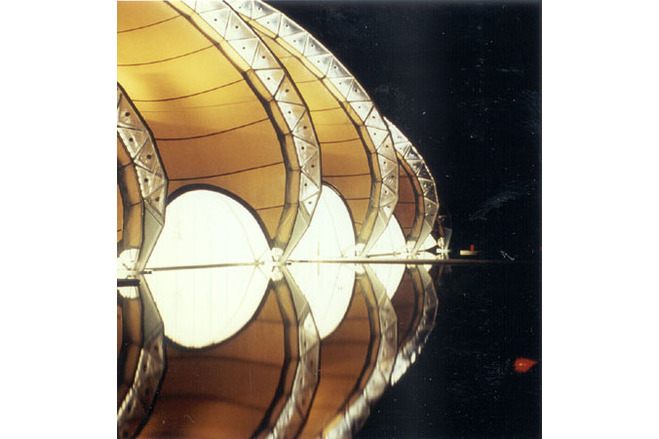

Six arches carry the roof membrane; they are three-chord lattice arches in the shape of a basket (three-centre) arch. Their triangular cross section varies over the arch length, with a maximum size at the apex, and tapers toward the arch support. They consist of 1764 single tubes in 441 different lengths and configurations. The arches are joined by six prestressed cables under the membrane. These stabilising cables are connected to the arches through pyramid-shaped outriggers to stay clear of the membrane curvature.

Substructure, foundations

The continous reinforced concrete ground slab with foundation pads and strips under the walls of the lab buildings and under the arches were designed for a live load of 20 kN/m². The arch feet are supported on the water level plain on reinforced concrete foundations, which are seperated structurally and visually from the ground slab.

Membrane

The membrane material of the roof is a PVC-coated polyester fabric with a tensile strength of 150 kN/m in warp and weft (fill) direction, which is equivalent to a type-4 membrane in the German classification.

The membrane is prestressed between the arches and the edge cables connecting the arch feet. The edge cables are run in membrane sleeves reinforced by webbing. At the arch supports they are connected with an adjustable connection made from a perforated flat steel plate. Along the arches the membrane is connected adjustably Through a garland cable with top and bottom cornerplates and threaded U-bolts. For waterproofing a membrane apron is connected to the roof membrane on the outside by a zipper along the bottom chord tube. The arches are covered by a transparant, prestressed plastic sheet, thus weather-protecting them economically and simultaneously keeping the arches visible and transparant membrane tensioned between roof membrane

Description of the environmental conditions

Building site - situation

The building is situated like an island in the middle of a rectangular pool and follows the outline of the foundations of a convent which once occupied this site; of the original buildings on the site a chapel and a dry-stone masonry aqueduct still exist. The artificial lake serves as a fire well and cools and animates the environment through natural evaporation and reflections. The lake, lines all around with old olive trees, is bridged over at the longitudinal sides of the building by two access ways, which form the main entrances to the building.

Services

Lighting

The truss arches are covered with a clear transparant PVC-membrane, providing additional natural lighting from above and keeping the arch structure visible at the same time. Cover strips and aprons are also made from transparant PVC-sheet. Due to the translucent membrane work is possible by day without artificial lighting. At night the building is lit by indirect halogen lighting against the roof membrane radiating from the balustrades of the lab buildings.

Ventilation, air-conditioning

For functional and safety reasons, the large air volume under the membrane roof must be airtight. By means of a simple ventilation system (on one longitudinal side the supply air comes in and on the other side the exhaust air is extracted), through shading by the roof membrane and due to the lake, an air-conditioning was not required despite the high outside temperatures. The inside temperatures correspond to ones under a free staning, naturally ventilated tent, I.e. the outside air temperature in the shade. Offices and lab spaces have independent air-conditioning.

[Soft Shells, Hans-Joachim Schock, p43-46]

General comments, links

Cost of the membrane circa 300000 lire/m2 (155 EURO/m2) in 1990.

Teil 9/21: Forschungszentrum in Venafro

Arch & Life 36/1990

Bouwen met staal

Canobbio

Verso un processo integrato

Research Laboratory Venafro, Pozzilli, Italy

Tensile Architecture in the Urban Context

Textile Components in Building Construction

Architectural Review 1992 March

Birdair Tensioned Membrane Structures

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Cable

-

Material Fabric/Foil

Polyester

-

Material coating

PVC

Main dimensions and form

-

Covered surface (m2)

2700

-

Total length (m)

34

-

Total width (m)

85

-

Form single element

Anticlastic

Duration of use

-

Temporary or permanent structure

Temporary

-

Convertible or mobile

Convertible

-

Design lifespan in years

11-20

Involved companies

-

Architects

Samyn and Partners

Setesco

-

Engineers

IPL Ingenieurplanung Leichtbau GmbH

-

Contractors

-

Suppliers

Verseidag-Indutex GmbH

Editor

-

Editor

Marijke M. Mollaert