San Nicola Stadium in Bari (Italy)

General information

-

Location address

Bari

-

Location country

Italy

-

Year of construction

1990

-

Name of the client/building owner

City of Bari

-

Function of building

Stadia

-

Degree of enclosure

Open structure

-

Climatic zone

Mediterranean - mild winters, dry hot summers

-

Primary function of the tensile structure

- Sun protection

Description

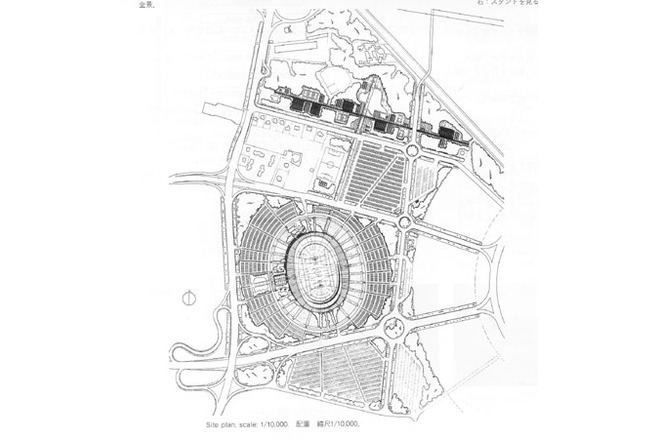

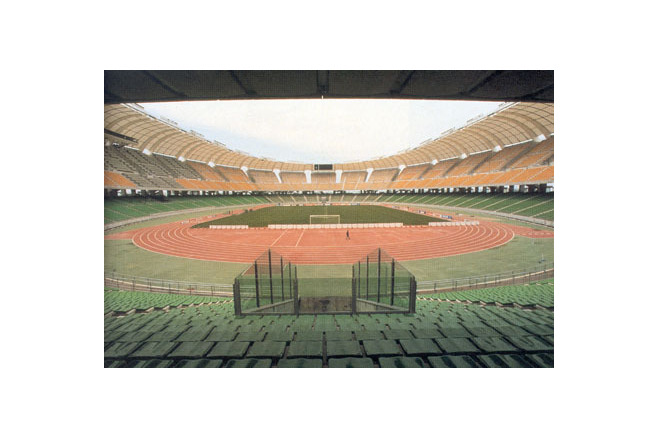

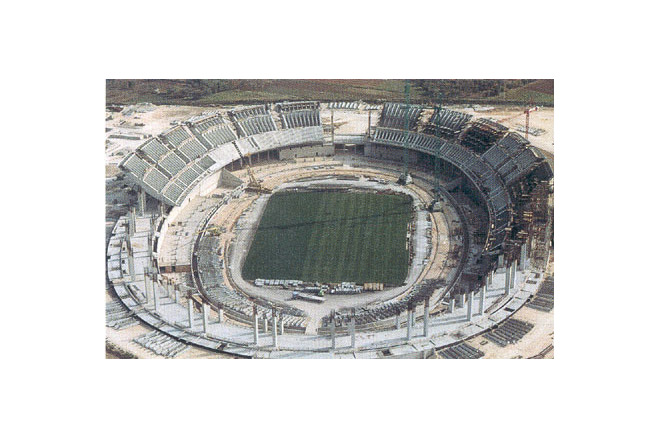

This is one of eight stadiums constructed for the World Cup held in Italy in 1990.

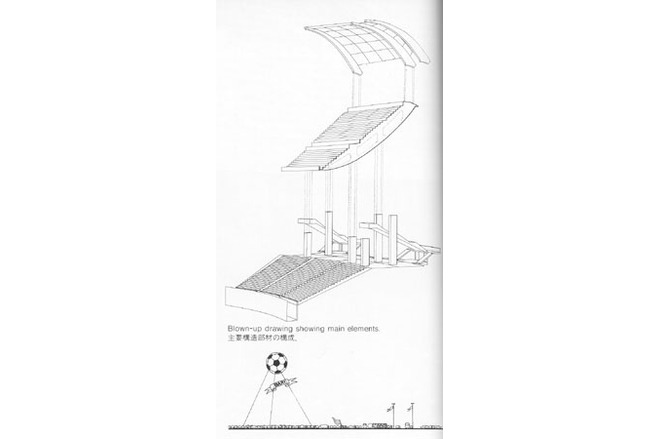

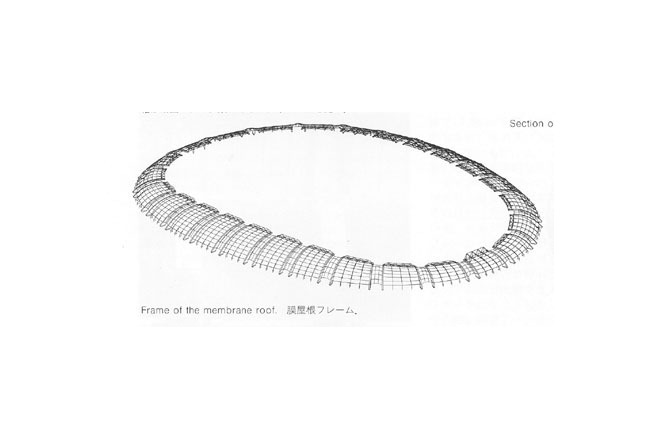

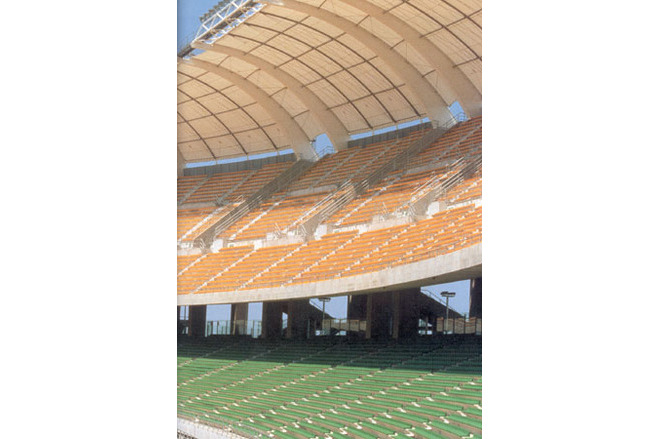

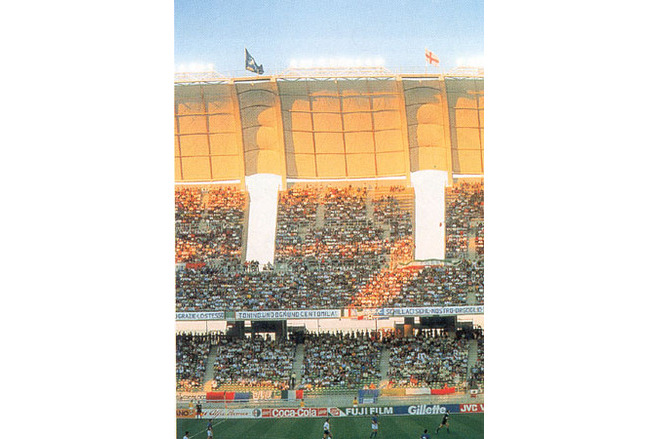

The spectators seats, which form an oval, were built by assembling on the site 310 crescent-shaped precast concrete beams. The upper spectators seats are divided into 26 enormous 'petals'. The slits between the petals make the building seem lighter and point out circulation areas, facilitating entry and exit and assuring safety for spectators. Computer simulation assured a clear field of vision for all seats. To protect the spectators from the hot sun and rain, a PTFE coated glass fiber roof membrane was designed in collaboration with Ove Arup & Partners.

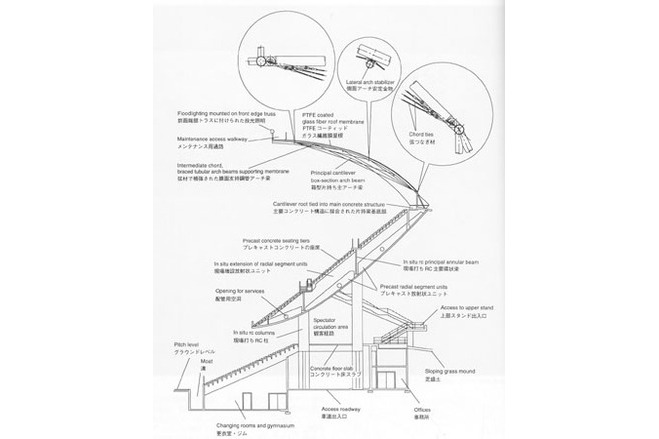

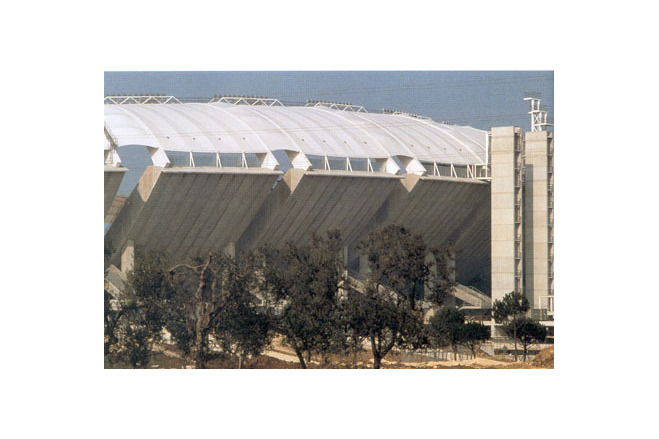

The principal structural members of this roof are box-shaped beams cantilevered from the top of he upper spectator seats, and the secondary members consist of a truss on th efront edge of the roof to support floodlights and a truss assembled from steel tubular arches and cables. The result assures the entire membrane surface will e under tension. To make certain that neither games nor spectators are disturbed by strong winds, wind tunnel experiments were undertaken at the Department of Aeronautical Engineering, Bristol University, using several of Arup's computer programs (such as the Fablon Program and the General Structural Analysis Program), and design was carried out with great care.

(Shunji Ishida, Renzo Piano Building Workshop)

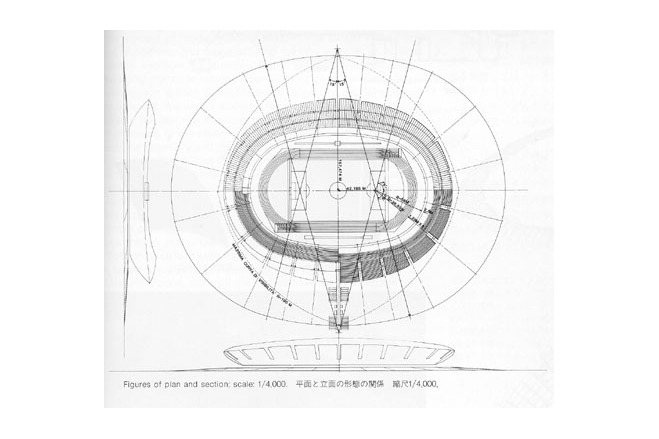

The roof consists of 26 large panels that individually cantilever from the concrete framework of the upper seating tiers. Between these are smaller panels which act as "structural springs" and close off the large slots between the upper seating tiers. The total area covered is 13250 m². Allthough the elevation of the upper tier and the cantilever span of the roof are constantly changing around the stadium, a degree of geometric repetition and systematization was achieved for the manufacture of the steel framework.

The cantilever span varies from 27 m to 14 m and at the edges of each roof panel are curved tapered box beams fabricated from steel plate. These are in effect a direct continuation of the concrete framework of the upper tiers.

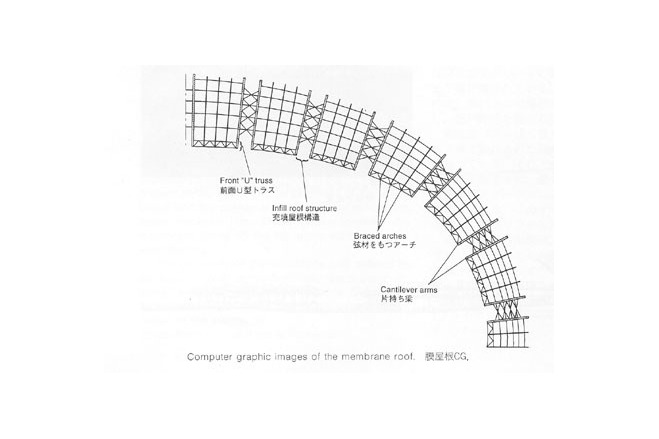

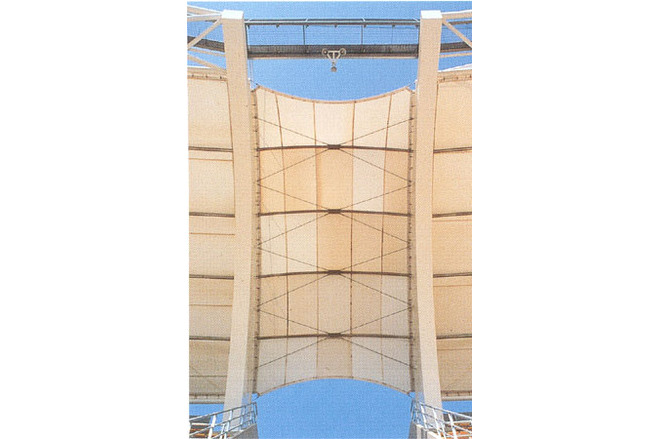

Linking the tips of these cantilevering box beams are a series of "U"-shaped trusses. These support the stadium floodlighting and provide an access route all the way round the whole roof. Each roof panel is further subdivided by 3 slender arch ribs which span between the back of the concrete stand and the "U"-shaped truss. To obtain extreme slenderness in these ribs their "in-plane" stiffness is enhanced by a fan of tie-rods emanating from each end.

Each roof panel in effect is a rib cage over which a prefabricated membrane panel can be streched. Each membrane is clamped down continuously on all 4 sides and held in contact with the 3 internal ribs by the biaxial prestress of the membrane and the presence of an external hold down cable between ribs. These cables pevent the membrane lifting off the rib in the worst cases of wind loading.

The geometry of the membrane was defined as an equal biaxial stress field and each panel installed within 408 kgf in both directions. Ove Arup & Partners also produced the cutting paterns on behalf of the contractor.

(Brian Forster, Ove Arup & Partners)

[Membrane Designs and Structures, Kazuo Ishii, p80, 82]

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Material Fabric/Foil

Fiberglass

-

Material coating

PTFE

Main dimensions and form

-

Covered surface (m2)

13250

-

Total length (m)

27

-

Total width (m)

14

Duration of use

-

Temporary or permanent structure

Permanent

-

Convertible or mobile

Convertible

-

Design lifespan in years

00-05

Involved companies

-

Architects

Renzo Piano Building Workshop

-

Engineers

Arup

-

Suppliers

Verseidag-Indutex GmbH

Editor

-

Editor

Marijke M. Mollaert