Open air theatre Tecklenburg - refurbished

General information

-

Home page

https://www.form-tl.de/en/project/open-air-theatre-tecklenburg-d/

-

Location address

Tecklenburg

-

Location country

Germany

-

Year of construction

1993

-

Year of replacement of membrane

2018

-

Name of the client/building owner

Freilichtbühne Tecklenburg e.V.

-

Function of building

Theatres & cinemas

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

double-layer

-

Type of application of the membrane

covering

-

Primary function of the tensile structure

- Rain protection

- Sun protection

Description

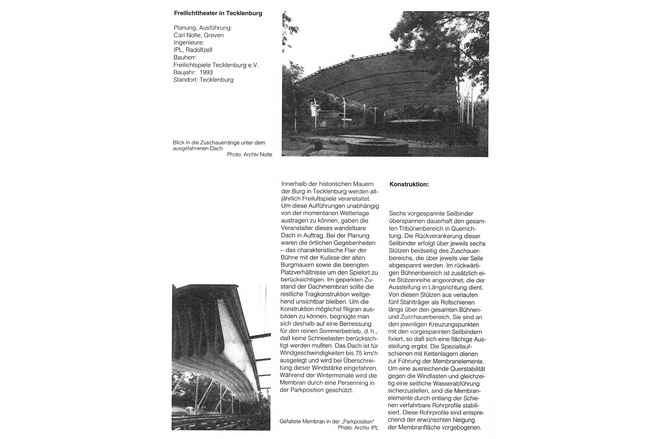

Membrane structures are often used as an interim measure and therefore rarely survive longer than 20 years or so. Textile structures in particular stand out in this context du to their special aesthetics and their demolition often means that some true engineering works of art are lost. One exception is the roof of the open-air theatre in Tecklenburg – it is a fine example of just how durable lightweight constructions can be showing the potential inherent in such structures. 25 years ago,

Freilichtbühne Tecklenburg e.V. wanted a rain canopy for its annual summer festival. A retractable roof was developed by consulting engineers IPL, from which the formTL engineering office emerged in 2004.

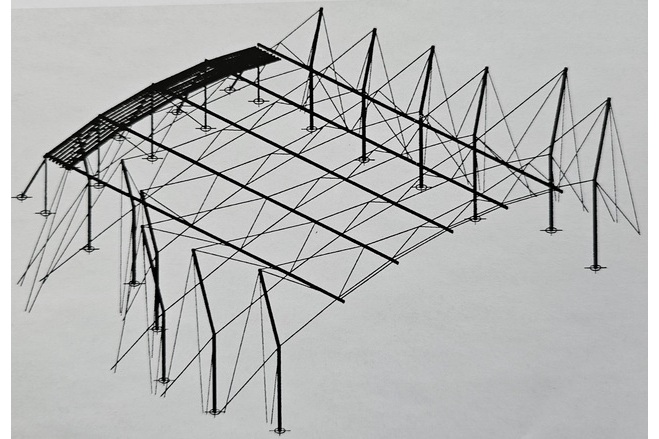

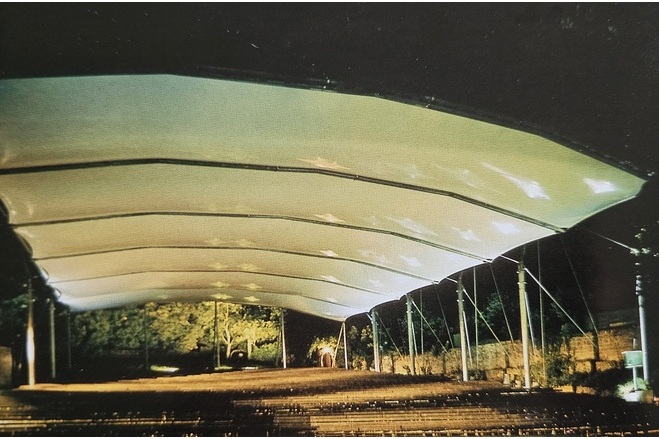

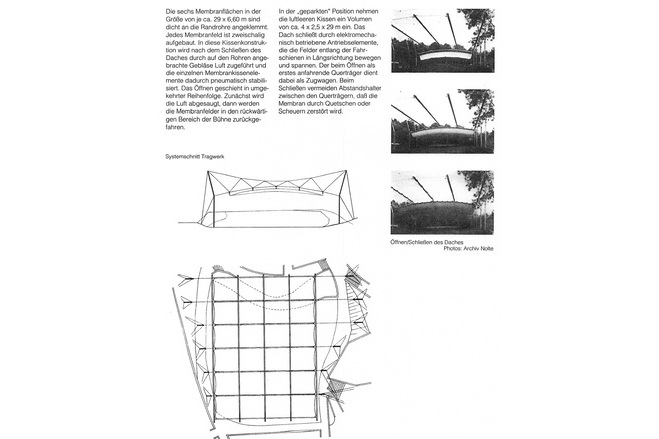

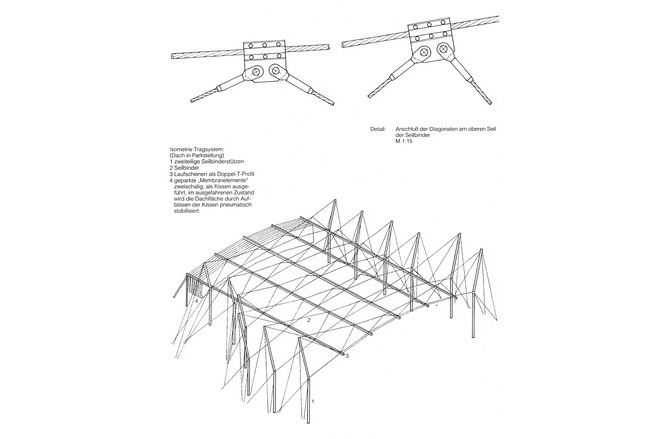

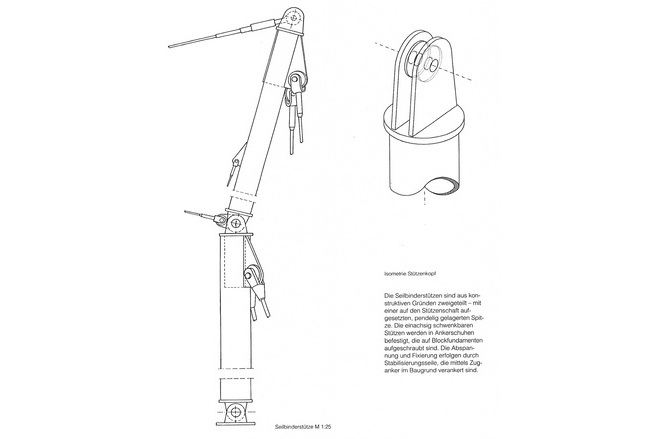

In poor weather the roof can be extended to shelter both the audience and the stage while in dry weather it allows a clear view of the sky. The structure consists of six filigree cable girders from which five longitudinal rails are suspended. Six steel aches with a carriage to which the double layered membranes are attached move along these rails. As soon as the roof is extended, the membranes are inflated into cushions, so making them wind-resistant, covering an area of 29x40m. When retracted, the membranes become parked in a type of garage which protects them from bad weather. This unique structure – there are only a few comparable structures of this kind – continued to win over the clients even after over 20 years of operation with its timeless design and high functionality. The society therefore decided to maintain and renovate the cushion canopy.

Membranes age at different rates: fixed structures usually have a service life of between 15 and 30 years. In the case of mobile structures, a service life of around 10 to 15 years may be expected as movement wears out the coating and fibres, so reducing the strength of the fabric more rapidly.

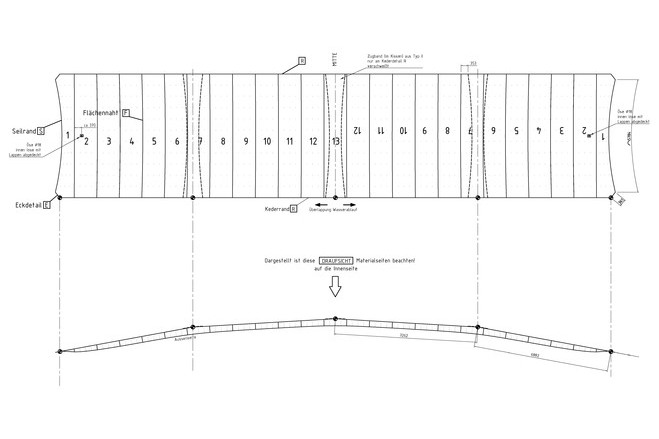

An inspection carried out in 2010 revealed that only the membranes needed to be replaced. Together with CENO Membrane Technology, who had already constructed the canopy in 1993 under the company name of Carl Nolte, formTL developed the refurbishment. One big advantage was that the project had already been designed 25 years before in 3D and all the documents, from the drawings to the analysis, to written correspondence, were kept in formTL’s digital archive. This meant that all that was necessary was to carry out a comparison of the measurements of the disassembled membranes and fittings with the old plans. As only a few discrepancies were found, formTL produced the cutting patterns which were adapted to the new folding membrane material within a month.

An optimized material was used for the highly stressed cushions which withstands more than 100.000 folds. The correspondingly manufactured membranes were transported to the site and were easily and quickly

installed. During the course of the refurbishment, not only the service life of the structure was extended but also the process of opening and closing the roof was accelerated with more powerful suction and pressure blowers.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

Main dimensions and form

-

Form single element

Synclastic

Duration of use

-

Temporary or permanent structure

Permanent

-

Convertible or mobile

Mobile

-

Design lifespan in years

21-30

Involved companies

-

Architects

IPL Ingenieurplanung Leichtbau GmbH

-

Engineers

form TL ingenieure für tragwerk und leichtbau gmbh

-

Contractors

Ceno Membrane Technology GmbH

-

Suppliers

Ceno Membrane Technology GmbH

Editor

-

Editor

Evi Corne