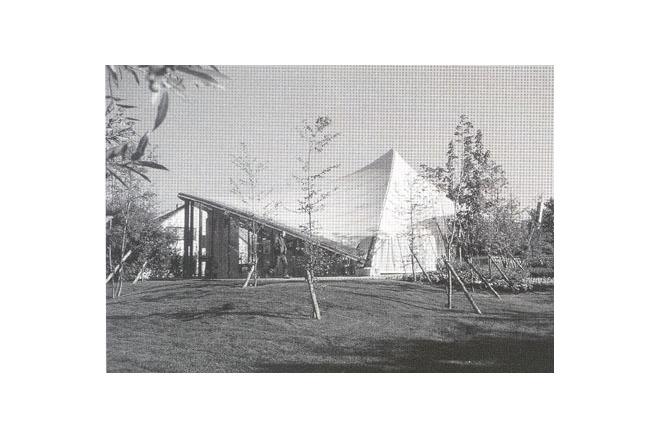

Butterfly House in Berlin (Germany)

General information

-

Location address

Berlin

-

Location country

Germany

-

Year of construction

1982

-

Name of the client/building owner

Prof. Dr med. Klaus-Werner Wenzel

-

Function of building

Entertainment & recreation

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

mono-layer

Description

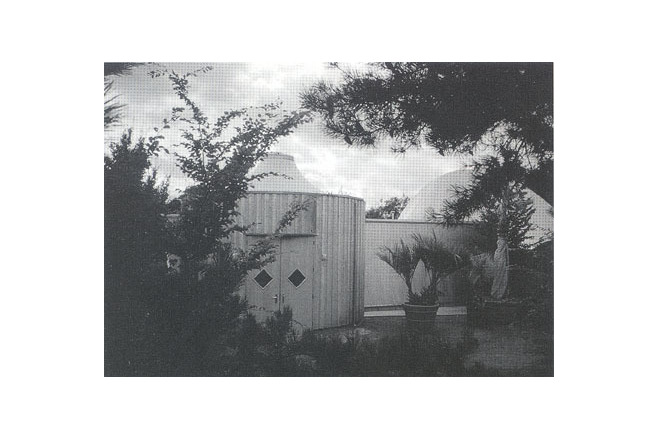

For the federal garden exhibition BUGA 1982 in the Britz district of Berlin a "church in the green" was built as a membrane structure. In 1993 it was converted for semi-commercial use as butterfly house and extended by several rooms. After 1982 the church remained unused for a long time and was ultimately destroyed through vandalism. In the years 1991 to 1992 a physician and butterfly lover searched for a location for a butterfly house and through the park and garden administration had this building recommended to him. Because of its dilapidation and the weathering of the membrane and due to the special climatic requirements of a butterfly house only the old primary structure was used and a new, thermally insulated membrane roof was planned by the same architect who designed the original BUGA "church in the green".

Brief

The brief contained:

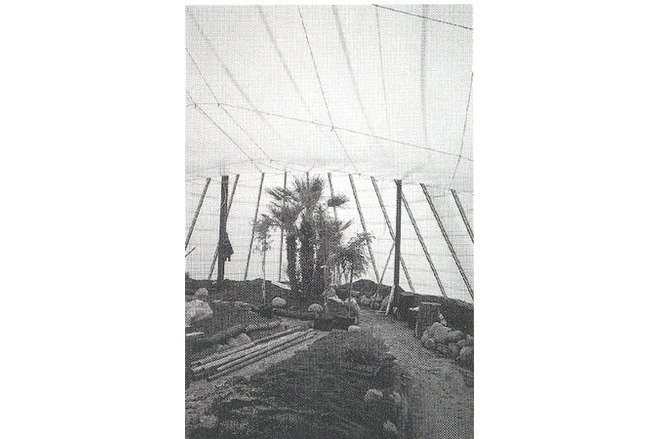

- a central area for the large flight room with visitor's paths and planting;

- an entrance lobby with cloakroom, ticket office and cash register;

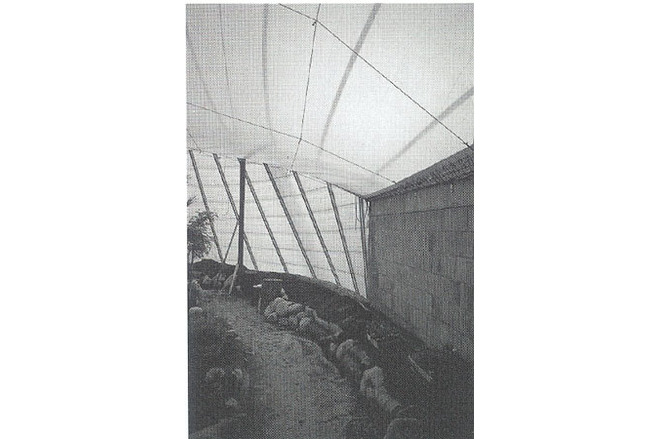

- a large showroom with displays o books, pictures and replicas of exotic butterflies - but no pinned butterflies (!); set in the room divider separating it from the large flight room are tubular perpex (acrylic glass) butterfly incubators where visitors can observe hatching;

- various ancillary rooms as well as

- an outside heating and climate container with a gas tank next to it.

Design

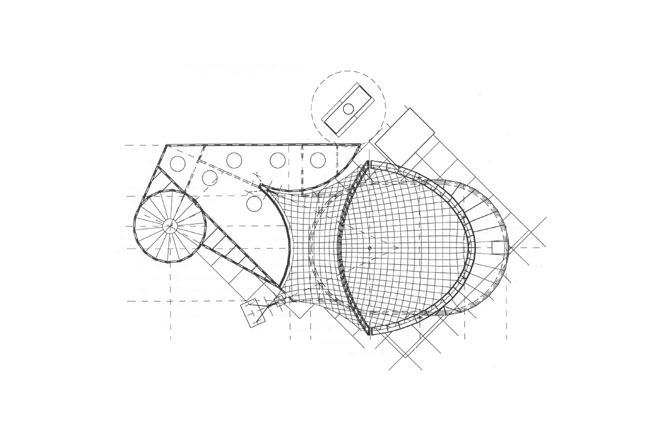

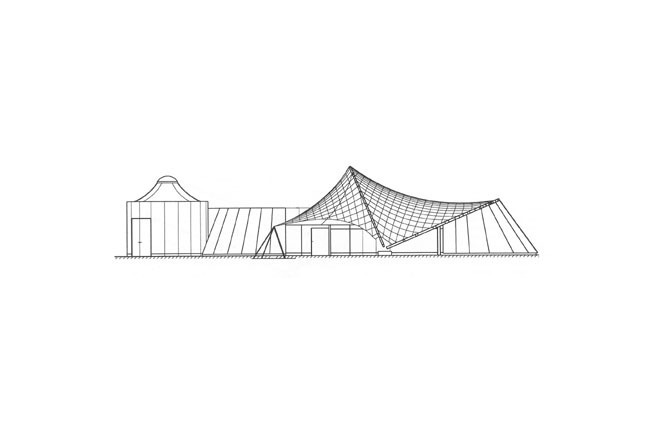

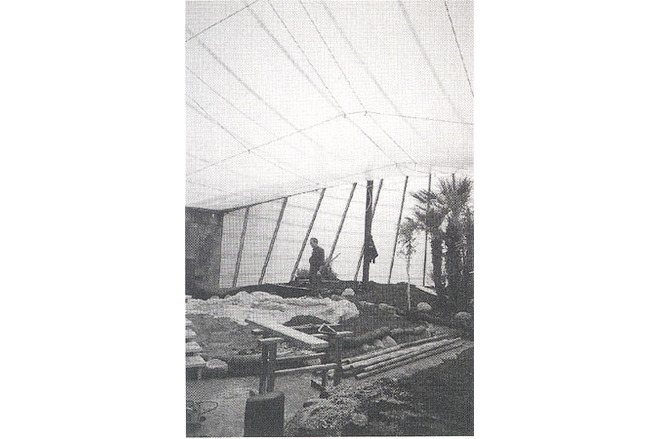

The refurbishment was in fact virtually a new construction but keeping two of three of the original glue-lam arches and the rear foundations. The existing oval plan shape of the hypar roof was added to by various extensions so that in plan it resembled a formal combination of the wings, body and head of a butterfly. Refurbishment and new construction were carried out allowing for the particular climatic requirements for raising and keeping exotic butterflies using modern building materials. Special importance was given to the room climate in the flight room with a required inside temperature of 26°C and a relative humidity of 86%. In addition a roof skin permeable for UV radiation was required to create a healty, pest-free climate for plants and animals. This was achieved through special roof and wall components: a clear double layer UV-permeable roof skin in the unit area, a thermally insulated, opaque membrane on the shaded north-west roof, and a hard cladding of transparent and thermally insulating polycarbonate twin web panels in the curved steep wall area under the outer glue-lam arch, all fulfilling the U-value requirements. The rear wall cladding forms a warped, transparent and thermally insulating polycarbonate surface.

Structure

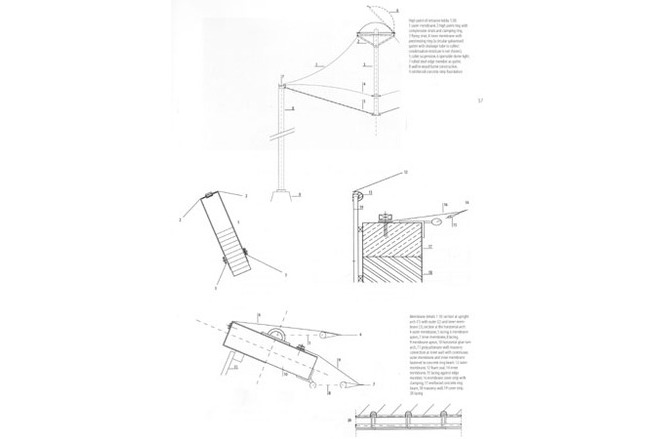

Two arches with differing cant form the main structure. Above it in the main area a double-layer membrane is stressed and is guyed towards the front entrance by an edge cable and support struts. The horizontal arch is supported by four vertical columns made from rectangular hollow sections. The polycarbonate glazing is fastened to sloping tubular mullions, which are pin-supported at the foundation and are fixed to the arch above though a movable tube sleeve, so that no vertical loads are carried into the foundations. The ancillary rooms have a wood frame structure with a flat roof. The structure of the entrance lobby consists of a wall in wood frame construction supporting a double-layer membrane roof and a suspended flying strut supporting the high point.

Description of the environmental conditions

Membrane

The outer roof of the butterfly flight room consists of an open weave glass fibre fabric with a mesh width of 5 mm, laminated on both sides with a 100um, high translucency and a UV-permeability of 80%. The smaller roof consists of PVC-coated polyester fabric, which was laminated with PVC foam for better thermal insulation. The edge of the outside roof exterior is formed by a movable tube frame to safely apply the prestressing forces, which are relatively high for this type of fabric. The connection to the arch is formed by a membrane apron. The membrane strip is streched by hand during installation and fastened under tension. This is a critical method which is not always recommended. It was chosen because the jacking distance was very short. Its success depends on the skill of the assemler; a re-tensioning is impossible.

[Soft Shells, Hans-Joachim Schock, p55-56]

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Cable

-

Material Fabric/Foil

ETFE-foil

Main dimensions and form

Duration of use

-

Temporary or permanent structure

Temporary

-

Convertible or mobile

Convertible

-

Design lifespan in years

00-05

Involved companies

-

Architects

IF Ingenieurgemeinschaft Flächentragwerke

-

Contractors

Editor

-

Editor

Marijke M. Mollaert