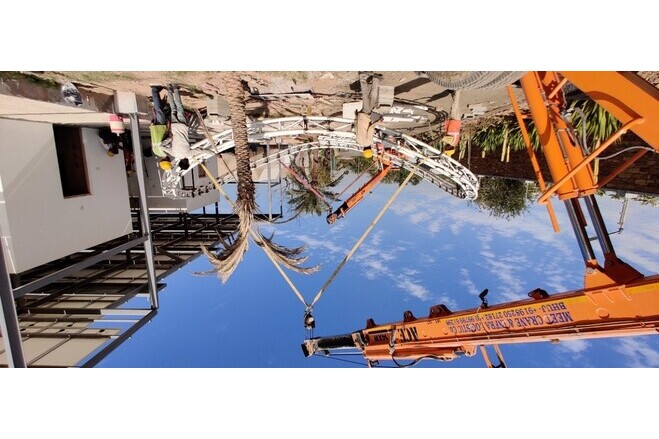

Entry Canopy for Kanchan Bungalow

General information

-

Location address

Kanchan Bungalow, Bhuj, Gujarat

-

Location country

India

-

Year of construction

2020

-

Name of the client/building owner

Agrocel Industries Ltd., Mr. Dipesh Shroff

-

Function of building

Houses

-

Degree of enclosure

Open structure

-

Climatic zone

Tropical - hot and wet all year

-

Number of layers

mono-layer

-

Type of application of the membrane

covering

-

Primary function of the tensile structure

- Rain protection

- Sun protection

Description

Design

A firm belief of Schafbock Design Workshop is that not every “great project” has to be big, cost a fortune or be for the purpose of “public service”. When it is designed by someone who masters the fundamentals of surface tensile structures, understands how forces flow through a system, blends physics and mathematics in simulation and unlocks the beauty of the natural forms, where all forces are “simply” in equilibrium, it results in something beautiful, inspiring, timeless and inspirational. Along with demonstrating these principles it needs to be designed with acute detailing and with understanding of the flow of water over the system (so that there are no ugly drips over a period or corrosion marks); in addition the choice of materials is something that was specially of interest and a challenge for this project, as the land is prone to fungal attack and corrosion due to the sparse landscape.

The Design was conceptualized simply as a typical “pringle chip” shape using a 12m diameter structure as the centerline. Everything was extrapolated from the system. Due to the fact that LS-Dyna, ixCube 4-10, Rhinoceros 3d and Grasshopper was used for various aspects of the job, it was of utmost importance that all the software spoke the same language. This was achieved by using “mathematics”. All information flow between the software happened through numbers, be it in terms of connectivity of members, exchange of prestress forces or geometry coordinates. IxCube 4-10 as a software was very helpful in developing the information flow. Using ixCube 4-10 also helped in developing accurate cutting patterns which significantly reduced production time and errors on site. A 3d site survey that was undertaken on site after finishing the steel structure, gave a very small deviation from the original design: this stands testimony to the fact that the quality check, design detail geometry, quality of work and continuous monitoring of the structure during production really paid off in the long term.

Challenges

To be able to translate a trigonometric curve onto site, is an arduous task, especially while dealing with craftsmen who are illiterate and depend on two dimensional drawings to be able to fabricate work. Therefore, programs were written, multiple sampling and testing were carried out for cables, junctions as well as the fabrication protocol, to ensure that the structure geometry would not pose any surprises when it was assembled on site. The Software ixCube 4-10 had a big role in simplifying the process, thanks to its flexibility and ease of operation.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Hybrid

-

Type (code)

Sattler 745 Polyplan Tent Light

Main dimensions and form

-

Covered surface (m2)

130

Duration of use

-

Temporary or permanent structure

Permanent

Involved companies

-

Architects

Vipul Mehta

-

Engineers

SCHAFBOCK DESIGN+WORKSHOP

-

Contractors

SCHAFBOCK DESIGN+WORKSHOP

-

Suppliers

Sattler PRO-TEX GmbH

Editor

-

Editor

Evi Corne