Carlos Moseley Music Pavilion in New York

General information

-

Location address

New York

-

Location country

United States

-

Year of construction

1991

-

Name of the client/building owner

New York Philharmonic and the Metropolitan Opera

-

Function of building

Entertainment & recreation

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

mono-layer

Description

Design

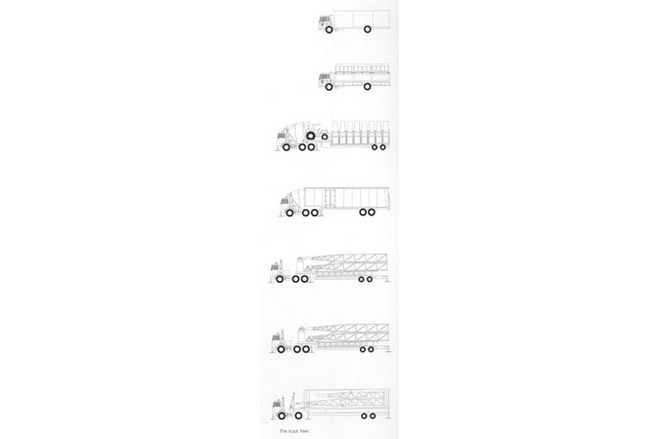

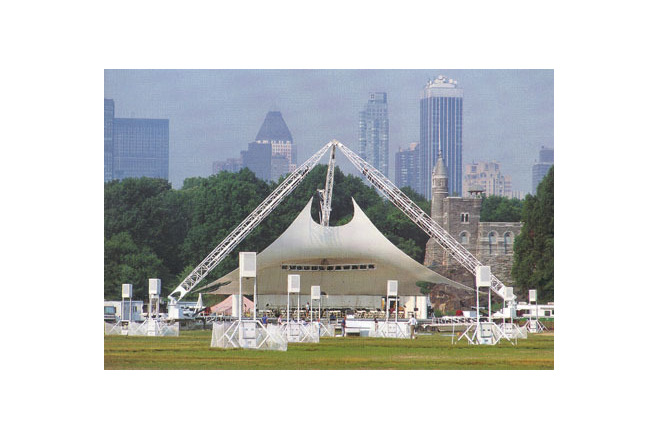

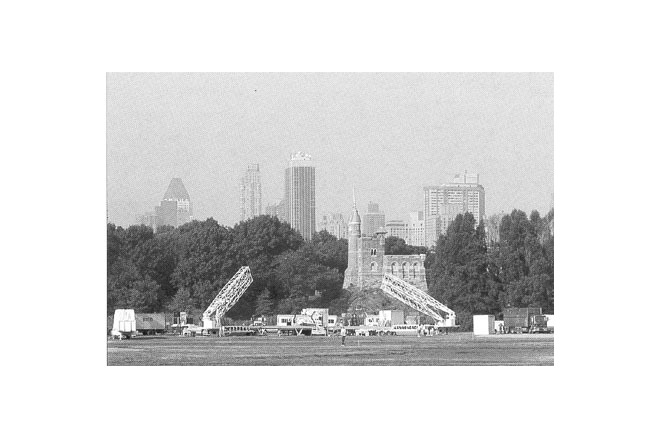

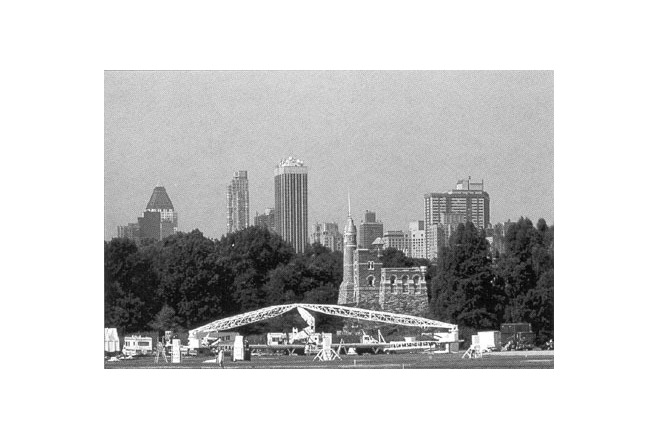

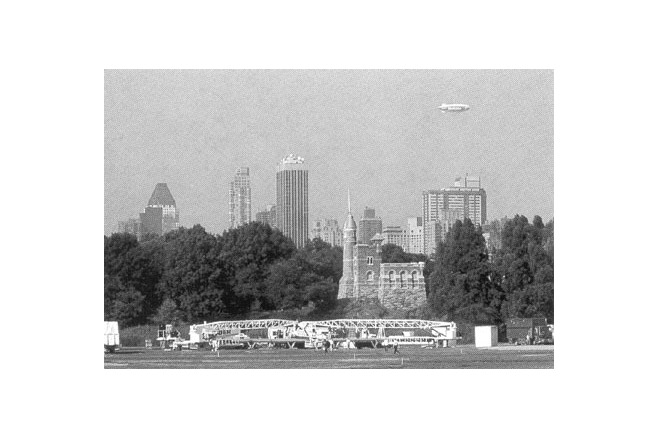

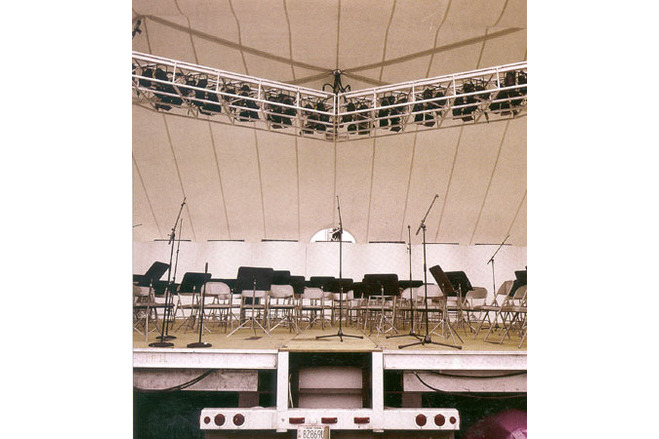

With an audience distributed over many different boroughs, New York City traditionally has used portable stages for outdoor summer concerts. The new $3.4 mill. Carlos Moseley Music Pavilion - named after the chairman of the New York Philharmonic who, in 1965 introduced free summer concerts in the park - was to be used in the first summer for 30 concerts and performances in 16 parks in five boroughs. It is a newly developed, fully mechanised tensile structure, which is erected from five semi-trailers, two trucks and their loads and offer a stage large enough for a full orchestra and chorus. Provided there is firm ground and vehicle access, speaker towers, amplifier plant, stage and membrane roof can be set up within six hours. After a performance the 288m² large open air-stage (276 m² of it under cover) can be disassembled and loaded in the same time, transported to the next location and to be set up again the following day.

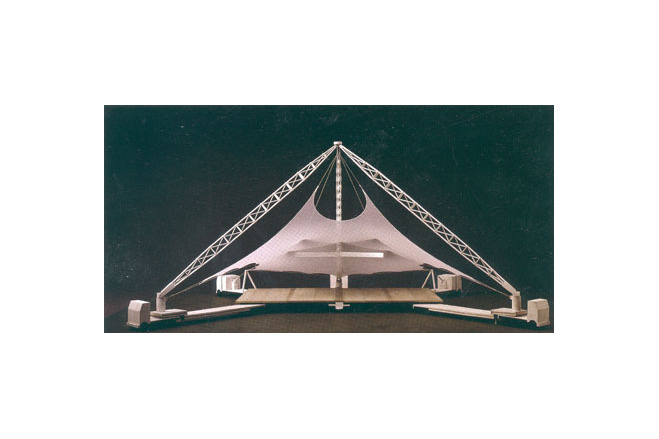

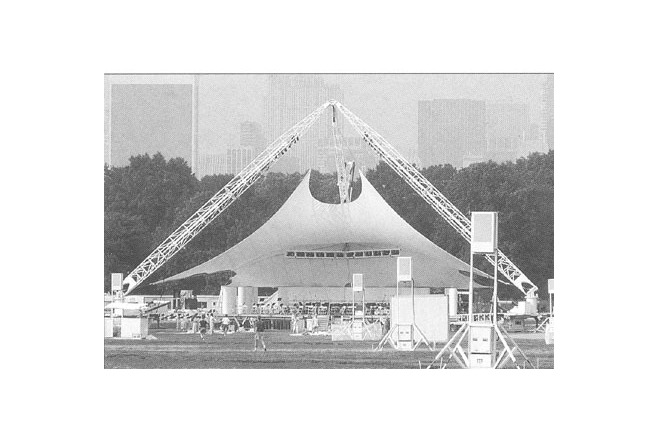

To avoid obtaining special authorisation each time the stage is moved, weight and dimensions of the vehicles had to correspond to the US highway regulations, which stipulates a maximum height of 3,95 m and a length of 13,7 m for a tractor trailor bed and its cargo. Because of its rotating and hydraulically unfolding girders it also had to be approved by the department for Cranes and Derricks, the authority responsible for movable buildings. Without permanent foundations it did not come, however, within the responsibility of the Department of Buildings. The design strategy was to allow the shape and geometry of the structure to be completed determined through technology. The roof membrane received its form from the requirements for sound reflection and rain protection for the stage. The architectural quality was designed into the proportions and the interaction of the different elements. When the pavilion is illuminated at night, the sructure disappears; only a hovering canopy remains visible, as a coloured backdrop for the performers on stage.

Technical installations, equipment

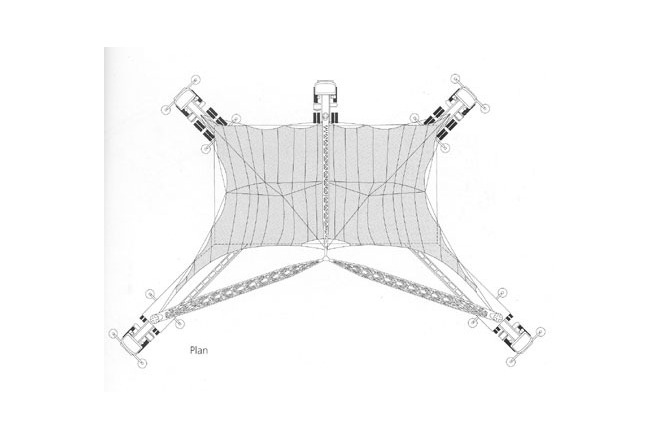

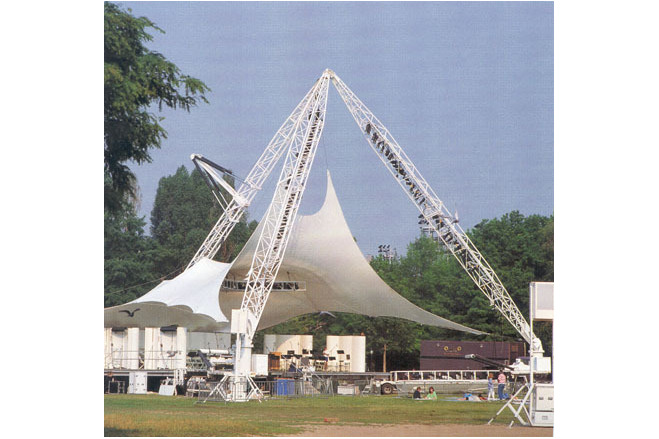

For images and subtitle projection an inflatable, circular membrane screen (Ø 4,8 m) is suspended above the membrane. The tripod trusses in front simultanously serve as rigging for the theatrical lighting with fixed wiring; an additional aluminium truss for overhead lighting is suspended from a hanger cable, supporting also the membrane at mid-section.

Acoustics

The audio system claims to produce outdoors the acoustics of an actual concert hall. The sound system was developed by Jaffe Acoustics exclusively for this project. The sound is transmitted via radio from an audio-visual control located 60 m from the stage to 24 speaker towers, set up in a semicircle of concentric rings in front of the stage. The battery-powered speakers, each on four collapsible legs are unfolded and raised telescopically to a height of 4,5 m and produce an almost ideal sound distribution and consistent sound level. The acousticians calculated and installed a delay of a fraction of a second in broadcasting music, corresponding to the time needed by the soundwaves to travel from the stage to the front speaker row. So the illusion is produced, that the amplified sound comes from the stage. The central speaker is the loudest, focusing attention on the stage. A slight delay in the sound transfer from the rear speakers simulates the reverberation of sound, which a listener would hear from the rear wall of an enclosed concert hall. Similarly the side speakers produce the effect of sound reflecting off the walls to the left and right.

In addition the saddle-shaped membrane, tied to the rear and the sides of the stage, reflects the music, and is supported in this by a semi-circulair wall of aluminium reflector panels with plywood backing, standing on the stage.

Description of the environmental conditions

Structure

Stage

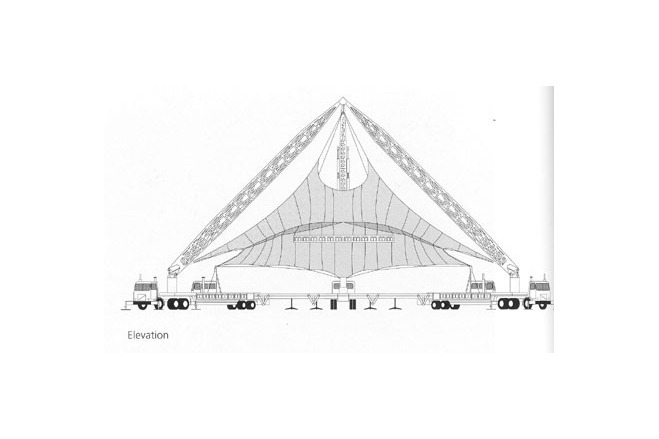

The hinged stage floor (12,3 x 23,7 m) of eight marine plywood panels is carried by six lightweight aluminium beams, transported folded like an accordion and opening automatically with the aid of hydraulic pistons. The corners and the rear centre of the stage rest on a 21,3 m long and 35,9 m wide substructure set up beforehand.

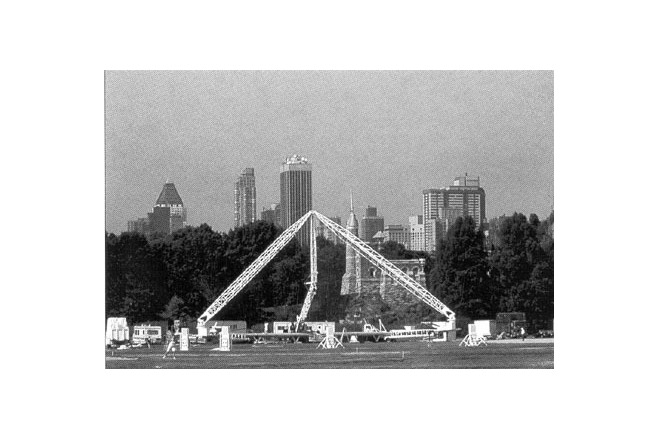

Roof

The tripod trusses consist of a painted four-chord tubular truss: the two front trusses have a length of 26,4 m; a rear girder acts as a hydraulic hoist lifting the front trusses. The front girders are first unfolded to their full length; then fastened to the rear girder. As the rear girder unfolds with the aid of a hydraulic hinge, it raises the entire tripod to a maximum height of 20,7 m. Once fully elevated, a sliding steel pin locks the hinged truss into a stable tripod structure.

Foundations

Without requiring foundations or fixed anchorages to the ground, the trucks can be weighed with concrete ballast to counteract the thrust of tripod and tensile membrane. For the stage retractable foot pads are unfolded hydraulically and adjusted in height to provide suitable support points on uneven ground.

Roof membrane

The roof skin consists of a PVC-coated polyester fabric (Ferrari type 10025 with Fluortop T) with a dirt-repellent PVDF-topcoat and it has a tensile strength of 3,92 kN/5 cm in warp and 3,80 kN/5 cm in fill direction. Due to large variation in erection the prestress of the membrane varies between 3,5 kN/m and 17,5 kN/m in warp and fill direction. The seams are high-frequency (Hf-)welded.

The roof is assembled from six individual panels. Its 52 cutting pattern strips have a nominal width of 1,67 m. The total membrane surface is 339 m².

For maximum rain protection multiple edge cable scallops along the sides and the rear make it possible to draw the roof membrane and its corners as close to the stage edges as possible. Kevlar ropes (Ø 19 mm) were used for the edge. Due to their flexibility and high strength they can remain in the edge cable pocket when the membrane is rolled up for storage, thus cutting at least 45 minutes from the otherwise required installation time, compared with the stiffer steel cables used for hangars and guys which had to be re-inserted into the edge cable sleeves each time.

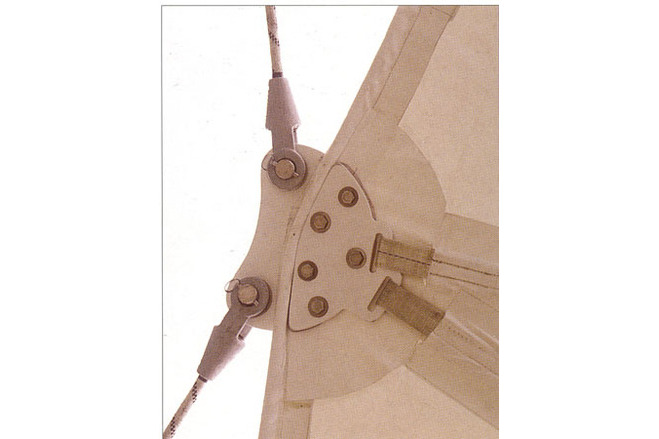

Aluminium corner plates and an additional membrane reinforcement at the corners serve as connection with the guy cables, anchoring the membrane in the structure. Man-made fibre webbing installed in pockets under the membrane surface and so caters for sufficient curvature.

The kevlar ropes will probably have to be replaced every two years, while the membrane has a service life of well up to twenty seasons depending on its handling by the construction crew, trained specially to raise and strike the pavilion.

Assembly

One truck transports the fabric membrane and lighting, a second one the electrical distribution and the stage equipment. One of five semitrailers carries the stage and the rear truss girder, two others the two front griders and a forth the speaker towers. The fifth semitrailer contains folding beams, which open to provide the stage structure; from it hydraulic pistons unfold hinged panels, forming the stage surface.

The translucent membrane of the acoustics sail is transported rolled up in a protective ground sheet.

A forklift with special balloon tyres for minimal impact on the lawn places the twenty-four speaker towers around the site.

[Soft Shells, Hans-Joachim Schock, p168-170]

General comments, links

Cost: $3,4 million

Music Pavilion in New York

Le tensostrutture a membrana per l'architettura

Carlos Moseley Music Pavilion

Mobile Bandstand, NewYork, USA

FTL Happold: Carlos Moseley Music Pavilion, New York

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Material Fabric/Foil

Polyester

-

Material coating

PVC

Main dimensions and form

-

Covered surface (m2)

276

-

Total length (m)

12.2

-

Total width (m)

23.7

-

Form single element

Anticlastic

Duration of use

-

Temporary or permanent structure

Temporary

-

Convertible or mobile

Convertible and mobile

-

Design lifespan in years

06-10

Involved companies

-

Architects

FTL Associates

-

Engineers

Buro Happold

-

Contractors

Fabric Structures Inc.

Editor

-

Editor

Marijke M. Mollaert