Revealing cover for the EU Presidency - Amsterdam

General information

-

Location address

Amsterdam

-

Location country

Netherlands

-

Year of construction

2015

-

Name of the client/building owner

Neptunus Structures

-

Function of building

Office buildings & congress centres

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

mono-layer

-

Type of application of the membrane

covering

-

Primary function of the tensile structure

- Space defining elements

Description

Context

The EU Presidency will be hosted in the Netherlands from January until June 2016. A temporary convention center has been installed at a former navy base in Amsterdam. DUS Architects designed the façade for the main entrance. A sail-like design which refers to the history of the location as well as revealing the future showing large 3D-printed elements (Fig. 1).

Concept

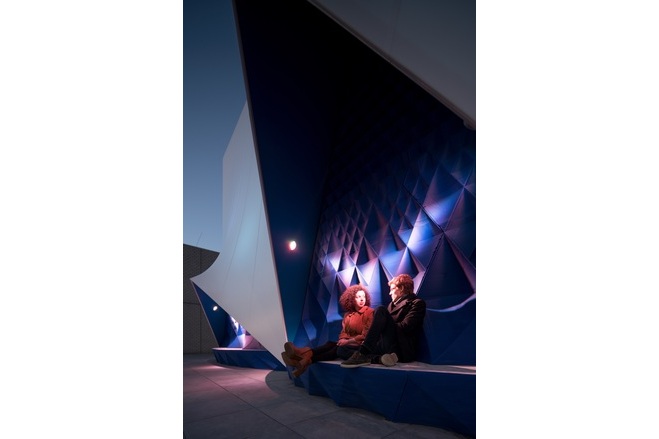

The façade gives image to the complex. The white screen is lifted up by invisible strings to open the building visually and physically to the public. This creates overhang, covering the entrance of the complex and creating alcoves for people to meet informal. The white screen is gradually lit at night by pulsating lights (Fig. 2).

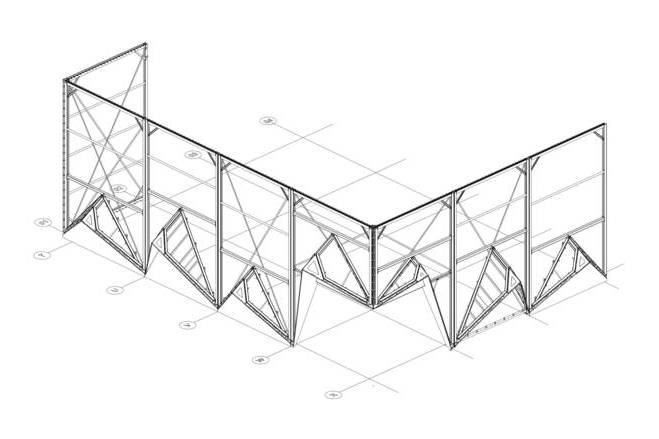

The sail elements have been carefully detailed to appear as clean and sharp as possible, no connections or tensioning devices are in sight. Along the overhang, the fabric is folded around the edge and clamped onto the steel frame. Side and top edges of the fabric fold around the steel frame and is tensioned to the back of the frame using springs. The structure of the façade is temporary and re-usable. It consists of eight different steel frames, easily installed and placed in front of the aluminium structure behind.

The benches show a pattern varying in shape and size, depicting the variety and community of the EU countries. They are designed parametrically and are fitted in precisely inside the alcoves. They are a commercial spin-off from the 3D Print Canal House project, a project of DUS architects, Tentech and other collaborators. For this project Tentech advices and validates the structural components produced by DUS’ \"Kamermaker\"; a life-size printer which can print elements up to 2x2x3,5m. The prints are made of a specially developed linseed oil-based bioplastic.

The area is open to public and will be take place from January 1, to June 30, 2016. [From TensiNews 30]

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Cable

-

Type (code)

Ferrari, Precontraint 502

-

Material Fabric/Foil

PVC - coated polyester fabric

-

Material coating

PVC

Main dimensions and form

-

Form single element

Anticlastic

Duration of use

-

Temporary or permanent structure

Temporary

-

Convertible or mobile

Mobile

Involved companies

-

Architects

DUS Achitects

-

Engineers

Tentech BV