Los Teros de Melilla

General information

-

Location address

Montevideo

-

Location country

Uruguay

-

Year of construction

2000

-

Name of the client/building owner

Los Teros de Melilla

-

Function of building

Multipurpose halls

-

Degree of enclosure

Hybrid structure

-

Primary function of the tensile structure

- Space defining elements

- Sun protection

Description

Description

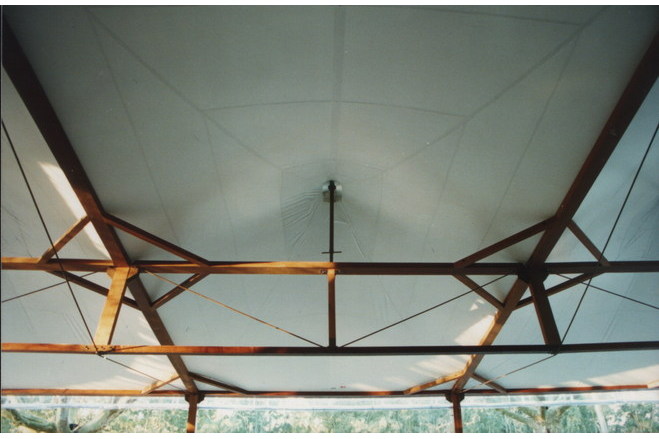

The project is composed of a pitched roof with a 15° slope that covers an 11m (36ft) space with a repetitive 6m (20ft) module. It is made of hardwood trusses and conic-shaped membranes in PVC, pre-stressed by means of central regulating masts, with lateral scrollable closures.

The membranes are screwed to the structure by means of wood screws with small aluminium plates.

The formal solution resembles the existing wooden construction. It was integrated on one of its sides to the main building.

Background Information

Los Teros de Melilla is an estate located on a farm near the city of Montevideo, dedicated to agriculture and cattle-breeding activities, but whose premises can be engaged for hosting parties and events of all sorts.

Objectives of the Roof

1. Eliminating direct solar radiation that can disturb ongoing activities.

2. Allowing entrance of natural light, at least 7%, so the indoor area is not darkened.

3. Rain protection.

4. Low building costs, so as to keep investment risks low, and not generate considerable losses should the enterprise not prosper.

5. Easy installation.

6. Special design to provide distinctive design quality.

8. Integrating with the existing building, without distorting the existing construction.

Reasons for Choosing a Prestressed PVC Membrane

1. It strictly complies with all the objectives.

2. When compared to other traditional systems such as glass, plastic, metal or concrete construction, these traditional systems do not meet all the requirements. Furthermore, some of them add new problems, such as increasing internal heat, blocking light completely, and more importantly, not offering the aesthetic and formal opportunities PVC membranes have to offer.

Design

The roof was generated with a lateral pitch for rain drainage to one side beginning at the height of the existing buildings. The roof is composed of three 11mx6m (36ftx20ft) independent conical shapes, so as to cover the area with the least amount of structural elements.

Design Process

Once the main design parameters were defined, there was special attention to avoid making the conical shapes too high-rising, and that at the minimum height the membrane could perform its functions correctly regarding tensions, as well as properly draining rainwater to prevent unwanted ponding.

The membrane was designed with the force-density method, and the cutting patterns defined by triangulating the surface.

The wooden elements were designed according to the tensions transmitted by the membrane, every detail studied in 3D solving all junctions with the metal fittings, which were specially designed for each node.

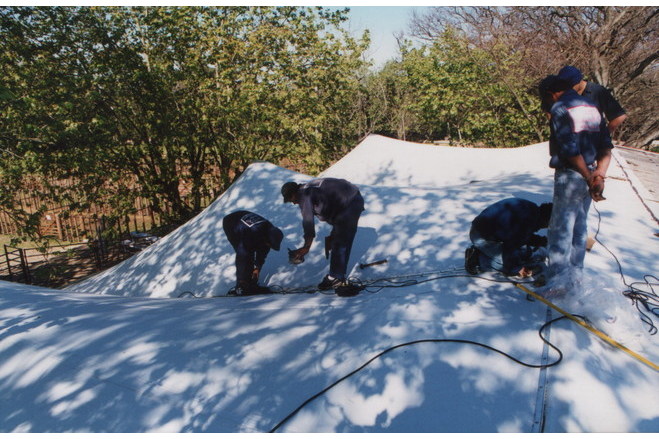

Building Process

All the woodwork was prepared at the carpenter's workshop, and the ironwork at the blacksmith's, the parts were then set up on site by means of a crane.

Next, the membranes were fixed to the perimeter with plates and wood screws, and ultimately the conical shapes were pre-tensed with the specially designed regulating masts.

Prestressing

The pre-tensioning of the membranes was done manually by means of three telescopic central masts with regulation bolts at their base.

Materials

The structure is made of 4x8" Patagonian Walnut (Lapacho), with painted metal fittings, anchored to the ground through concrete bases.

The membranes are made of polyester fabric PES HT 1100dtex, 5x5 threads per cm (12 threads per inch) with PVC coating, UV protection on the outside, a weight of 800gr/m2 (230oz/sqyd) and a breaking load limit of 30daN/cm (167lbs/inch).

Conclusions

The objective sought after by the roof was achieved to perfection, accomplishing an enjoyable space for holding events.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Type (code)

Polyester PVC-coated UV protection PES HT 1100dtex

-

Material Fabric/Foil

Polyester

-

Material coating

PVC

-

Weight (g/m2)

800

Main dimensions and form

-

Covered surface (m2)

200

Duration of use

-

Temporary or permanent structure

Permanent

Involved companies

-

Architects

Roberto Santomauro & Patricia Pinto

-

Engineers

R & R Fuchs

-

Contractors

Sobresaliente

Editor

-

Editor

Thomas Van der Velde