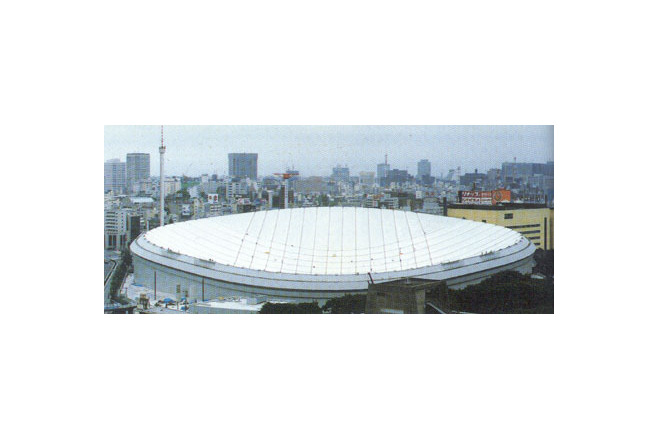

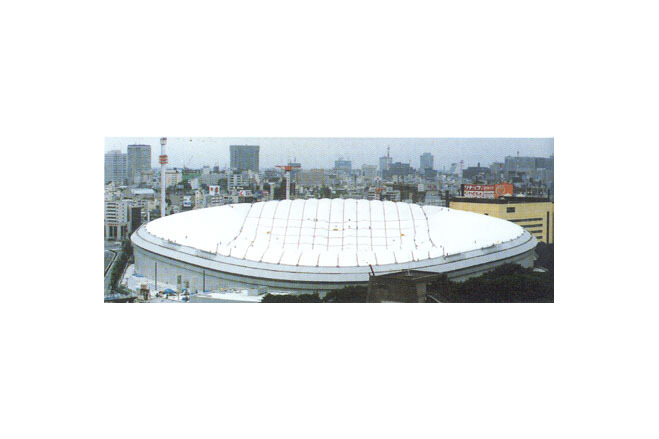

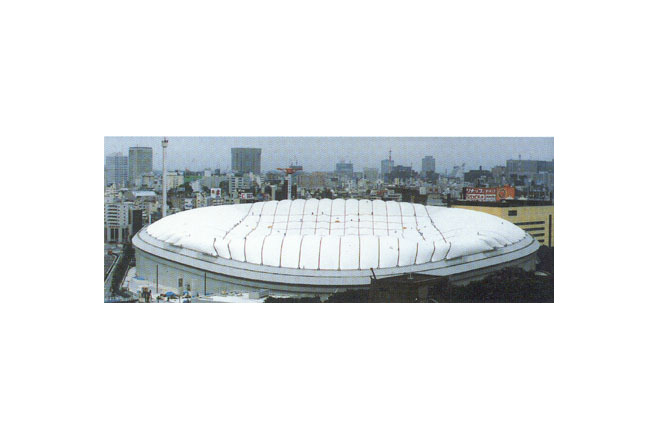

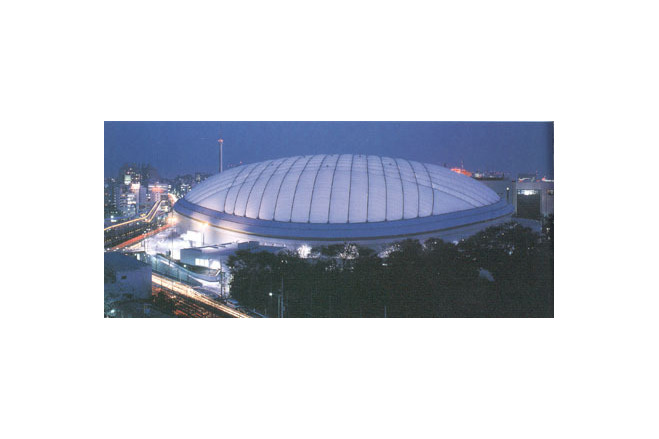

Tokyo Dome 'Bigg Egg'

General information

-

Location address

Sotobori and Hakusan avenues Tokyo

-

Location country

Japan

-

Year of construction

1988

-

Name of the client/building owner

Tokyo Dome Corp.

-

Function of building

Stadia

-

Climatic zone

Temperate - cold winters and mild summers

Description

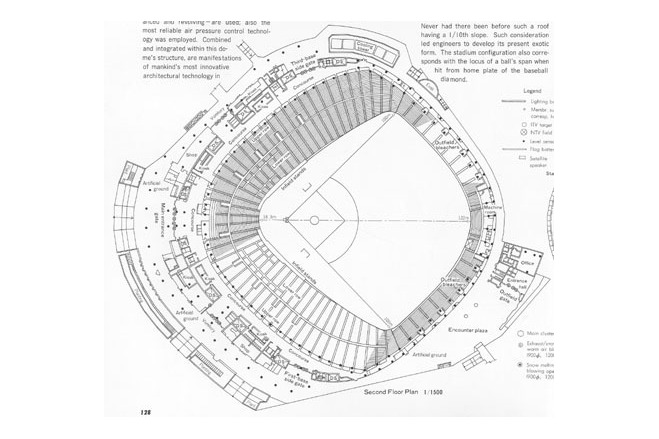

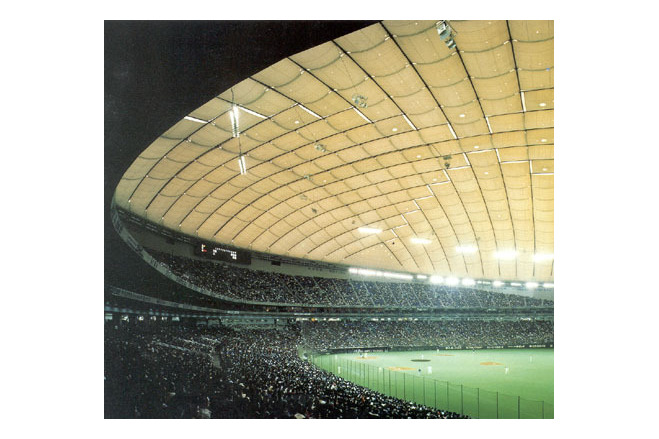

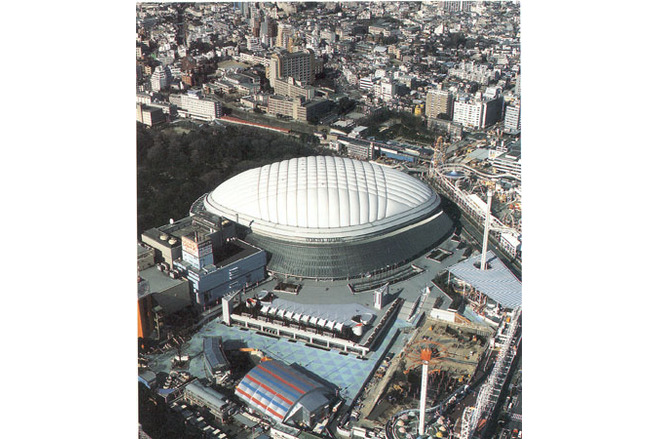

This building, surrounded by Sotobori and Hakusan avenues and Ushigome-Koishikawa Metroppolitan Road and situated close to Suidobashi Station on a Japan Railway line and Korakuen and Suidobashi subway stations, is ideally located for a large-scale spectator facility. An amusement park, a convention hall, a gymnasium and restaurants also share the site, forming a comprehensive recreation center. Around it is an existing urban area of office buildings and small and medium-sized stores, and next to it on the north side is the Koishikawa Kurakuen Garden, which has been designated a Cultural Asset.

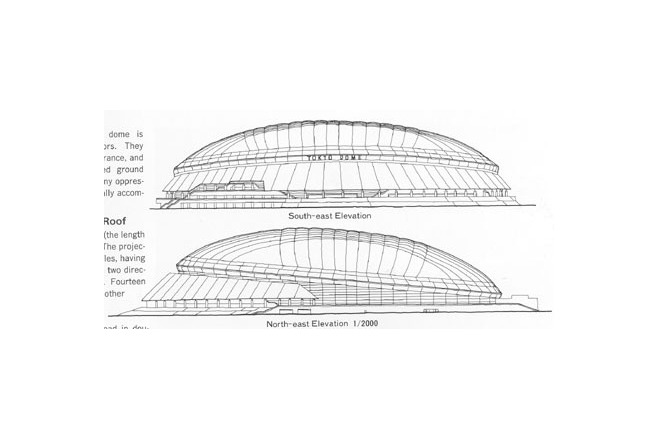

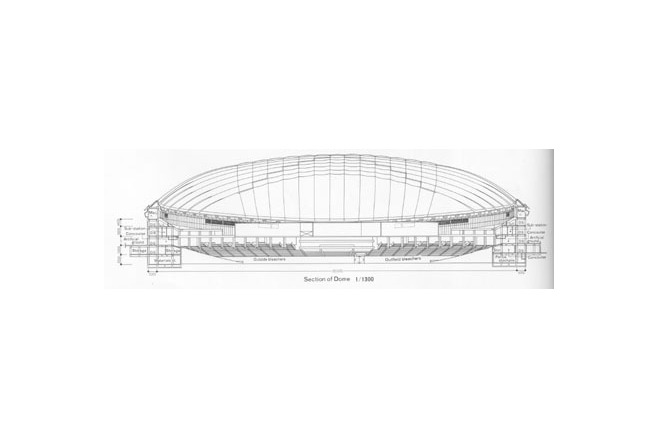

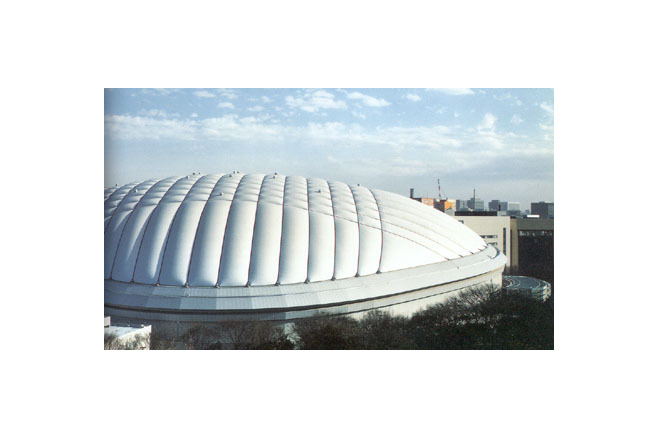

To adapt a large dome to this environment, the edge of the roof on the north side has been made 20 m lower than the edge of the roof on the south, producing an inclined membrane roof. A large glass canopy was added to the large wall on the south side to provide protection from rain and to give the building the scale of the neighbouring streetscape. The field is 5 m below ground level. A deck 5 m above ground level circles the facility. This facilitates the circulation of large numbers of spectators and makes the building seem even lower.

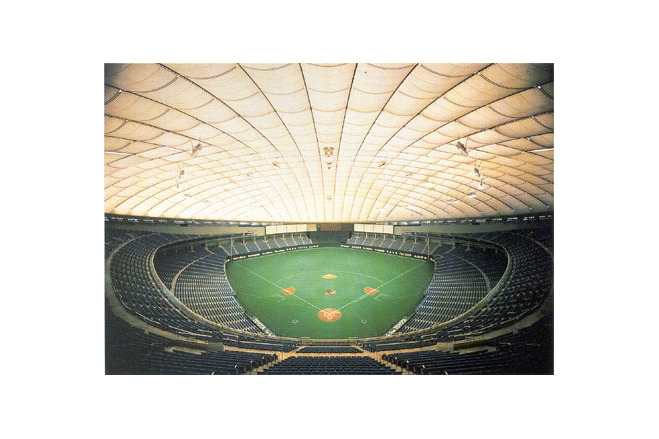

An AI (artificial intelligence) system has been established to manage the pressurized inflation and control supporting the membrane roof. Anemometers and instruments for measuring snowfall and displacement of the roof continually and automatically measure atmospheric conditions outside, and the system automatically adjusts the inflation pressure accordingly. The system automatically manages all elements related to inflation blowers that are in operation, the degree of opening of dampers, and the number of air balance doors that are open. It is also equipped with a manual control system for responding to special situations.

(Yoshio Tanno, Takenaka Corporation)

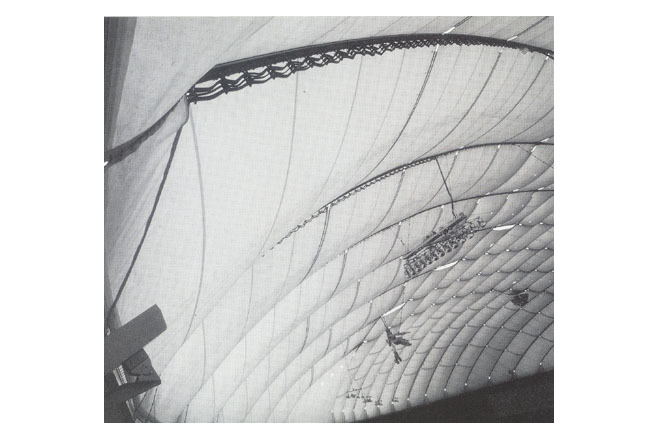

The roof in plan is a squarish oval which can be inscribed in a square 180 m to a side and whose maximal diagonal span is 201 m. The entire roof has a slope of 1/10 and the roof edge is kept low on the west side because of environmental concerns about the adjacent Koishikawa Korakuen Garden. The span-rise ratio is 0.124 compared to the sloping surface of the ring. The cables are structural spiral ropes with a diameter of 80 mm. There are 14 cables at a pitch of approximately 8,5 m in each diagonal direction, or 28 in all. The average fixed load on the roof, including fixed loads installed on the roof surface, is about 14kgf/m². Under ordinary conditions, the pressurized inflation system maintains inflation by raising the internal pressure 30mmAg (30kgf/m², or approximately 0,3 % of atmospheric pressure) above the external pressure, and in times of strong winds or accumulated snow, the internal pressure can be raised in stages to a maximum of 90mmAg in response to the level of the external force. In addition, a snow melting system reduces the snow load on the roof surface.

With respect to the construction of the air-supported membrane structure, work was undertaken in a deflated condition and at the end, the structure was pressurized and reached its inflated condition in a short period of time. During this process, the roof was in an unstable condition and the cables underwent considerable bending. The ends of the cables and the hardware fixing the membrane material to the cables had to be sufficiently flexible to permit these changes and were an important consideration in designing details.

(Yoshio Tanno, Takanaka Corporation)

[Membrane Designs and Structures in the World, Kazuo Ishii, p 237, 239]

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Cable

-

Material Fabric/Foil

Fiberglass

-

Material coating

PTFE

Main dimensions and form

-

Covered surface (m2)

116460

-

Total length (m)

202

-

Total width (m)

202

Duration of use

-

Temporary or permanent structure

Temporary

-

Convertible or mobile

Convertible

-

Design lifespan in years

00-05

Involved companies

-

Architects

Nikken Sekkei and Takanaka Corporation

-

Engineers

Nikken Sekkei and Takanaka Corporation

-

Contractors

Taiyo Kogyo Corporation

-

Suppliers

Chukoh Chemical Industries, Ltd.

Editor

-

Editor

Marijke M. Mollaert