US Embassy in London

General information

-

Home page

https://www.birdair.com/birdairs-durable-transparent-facade-sails-add-unique-flair-to-us-embassy-in-london/

-

Location address

33 Nine Elms, London

-

Location country

United Kingdom

-

Year of construction

2017

-

Name of the client/building owner

US Department of State

-

Function of building

Office buildings & congress centres

-

Degree of enclosure

Open structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

mono-layer

-

Type of application of the membrane

attached

-

Primary function of the tensile structure

- Sun protection

Description

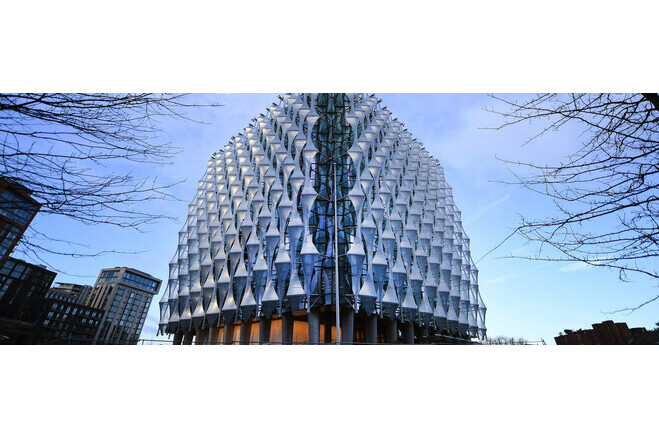

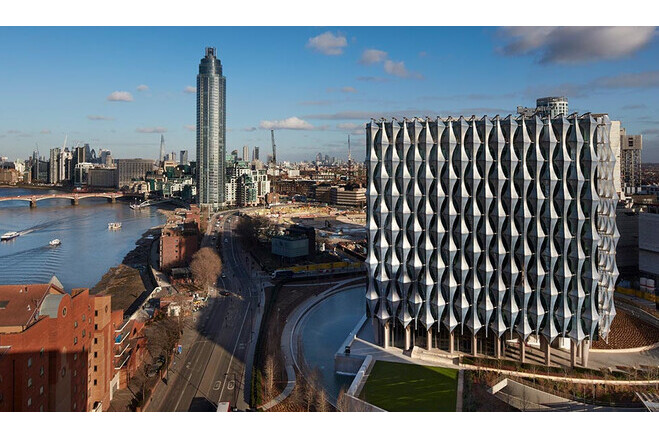

The new building, designed by Kieran Timberlake architectural office, found the balance of transparency and the requested high security. The building is a 65m tall glass cube cladded by a flexible translucent ETFE second skin, allowing a splendid view to the River Thames. 12-storys provide sufficient room for 800 staff and approximately 1.000 visitors per day.

The architects summed up their design idea as follows: “How can we build an embassy that reflects the core values of democracy - transparency, open- ness, and equality - and is welcoming, secure, and highly sustainable? 1 They solved this task perfectly: With high sensitivity and precise knowledge of the materials used, they designed a pioneering envelope for the building with a double-shell façade: The inner shell is made of solid multiple-layer laminated glazing. It guarantees the security required for this utilization. The outer shell, constructed as a curtain façade, consists of a large number of or- ganically shaped flexible sail surfaces made of ETFE-foils and a light sup- porting structure made of steel ropes, aluminium rods and carbon steel. Since both, the inner and the outer shell, are transparent, the view from in- side to outside remains intact despite the double shell structure.

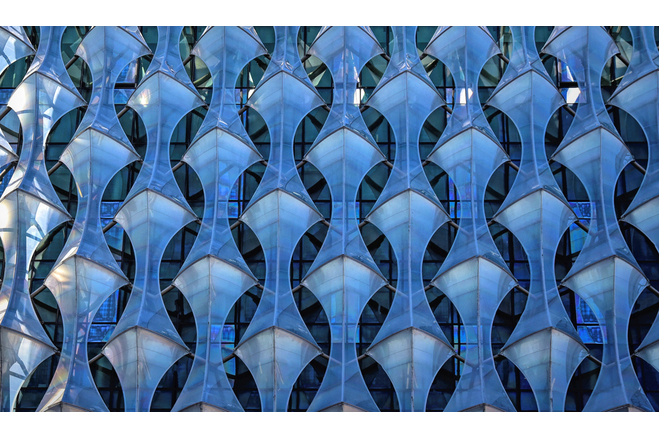

For the 399 sail surfaces the TensoSky-System from TAIYO was selected. The very thin film (here 250μm) made of the fluoropolymer material Ethy- lene Tetrafluoroethylene (ETFE) offers many advantages: it is transparent, light weight, elastic, flame retardant and weatherproof. As a rule, it does not require any special cleaning, as the rain washes away dirt particles from the smooth surface. In addition, the material is largely resistant to chemical and biological exposures. As a thermoplastic material, the clear ETFE foil can be 100% recycled. At the end of its lifetime the film can be completely re- turned to the material cycle. However, it is mostly reused in form of other products, rather than foils for architectural applications.

The sails have a special function here: The ETFE foils are printed with different grades of silver patterns, letting only a part of the sunlight pass. The printing reduces the glare from the sun and minimizes the heat gain of the building. Despite the printing, one can look through the film as long as it is lighter on the other side than on the side of the viewer. The spectrum of visible light is hardly changed by the films. As a result, the colours behind ETFE foils remain almost unchanged. Since the north facade is not exposed to direct sunlight, it has no ETFE sail area. Even without the north façade, the sails form a total surface of 8.125m². They are held in place by a light supporting structure made of steel ropes, aluminium rods (180t) and carbon steel “headmounts”. The supporting structure transfers the wind loads and the dead weight of the curtain facades into the building structure.

Detailed design, execution planning and assembly of the curtain façades were done by a joint collaboration of two companies of Taiyo Group: BIRDAIR Inc. (in North America) and TAIYO EUROPE GmbH. The assembly of such membrane structures, i.e. technical fabrics and foils, requires precise design engineering, high quality in fabrication and full knowledge of the re- spective construction methods and materials used. The installation on site must be carried out by specially trained climbers. Such installations follow a precise plan of positioning the elements of the supporting structure and the stretching of foils and steel ropes, component by component. The installers do this work while hanging on a climbing rope and secured with personal protective equipment. It is a sophisticated job for professionals.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Foil

-

Material Fabric/Foil

ETFE-foil

Main dimensions and form

-

Covered surface (m2)

8125

Duration of use

-

Temporary or permanent structure

Permanent

Involved companies

-

Architects

Kieran Timberlake

-

Engineers

Arup

-

Contractors

Birdair Inc.

Taiyo Europe

-

Suppliers

NOWOFOL

Editor

-

Editor

Evi Corne