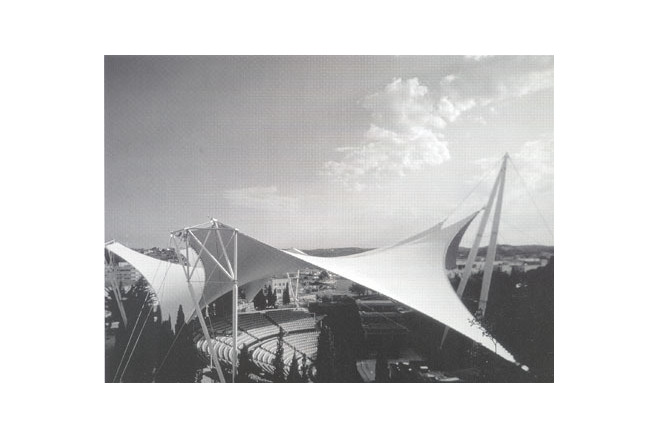

Auditorium roof CAMP DE MART in Tarragona (Spain)

General information

-

Location address

Tarragona

-

Location country

Spain

-

Name of the client/building owner

Ayuntamiento de Terragona

-

Function of building

Theatres & cinemas

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Mediterranean - mild winters, dry hot summers

-

Number of layers

mono-layer

Description

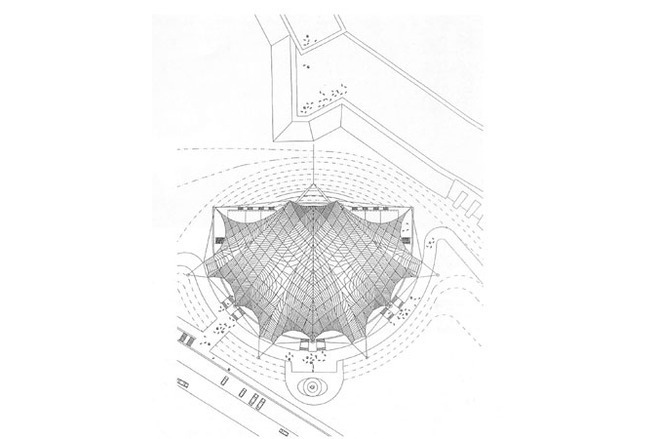

Structure

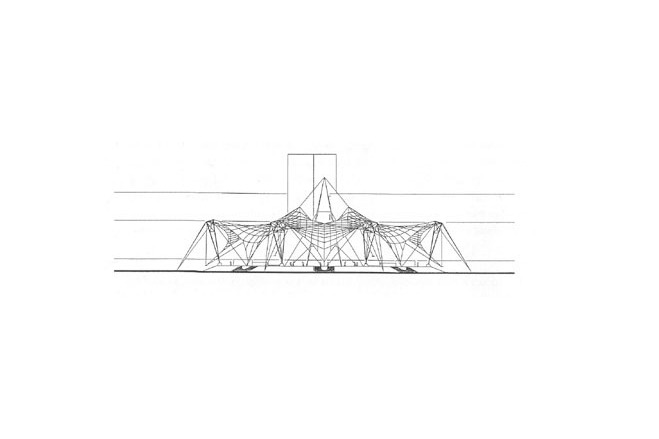

The main structure, nearly semi-circular in plan, consists of a roof membrane, strengthened at the edges by steel cables. It is supported by four V-shaped mast trestles around the edge, and by one A-shaped main mast on the axis of symmetry behind the stage. It is anchored at five guy cables between the lower V-masts, fastened to ground anchors as well as by one large guy cable on the axis of symmetry holding the main mast.

Despite the flat membrane shape there is just sufficient surface curvature available at each point. To avoid large displacements under snow load a system of snow cables was introduced in the middle of the roof.

A continuous ring cable joins the high and low points; its function is to hold the V-masts laterally, which are only guyed by three cables converging onto one base point. The roof drains naturally to the low points into floor inlets there. A gutter at the membrane edge is not provided; when rainfall is light, the clamping section along the edge acts as rain deflector, when rain is heavier, the water can overshoot the edge. The structure was analysed for the load cases of dead weight, snow and wind. An evenly distributed snow load of 40 kg/m² and a wind load of 110 kg/m² (corresponding to a maximum wind speed of 151 km/h) were assumed.

Membrane

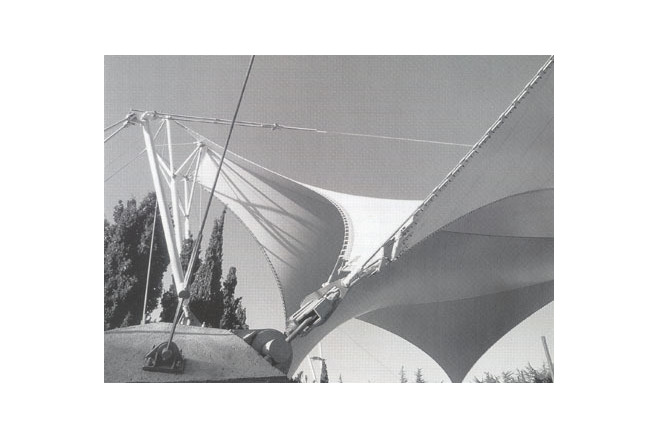

The roof shape can best be described as a modified symmetrical high point membrane. Along the edge there are five high points with different heights, he highest one lies on the axis of symmetry. At five intermediate low points the membrane is tied down. To avoid large heights and long membrane tips the high points were 'modified', i.e. dissolved into two points with a short edge cable lying between them. The high points are either anchored in V-shaped twin columns or connected by two tension ties to the tip of the A-shaped mast with an inter- mediate guy between them proceeding down to the ground.

The membrane consists of a high-strength PVC-coated polyester fabric (Ferrari Precontraint-1502-Fluotop) with a tensile strength of 8/7.8 kN/5 cm (warp/weft). The material is classified as 'difficult to ignite' (class 2 to Italian, class M2 to French standard). It is coated with Fluotop, a strong PVDF-polymer coating thus extending its service life. The coating forms anti-adhesive protection film against smog and other air pollutants and so visually prolongs the life span of the membrane.

For the membrane and their textile additions, edge cable pockets, membrane aprons etc., a reduction and safety factor was required between four and five to guarantee a very long service life. (The safety factor applied for coated fabrics on the short-term strength determined in load tests is made up of a real safety factor, allowing for a variation of the manufacturing quality and the applied loads as for conventional building materials, steel, concrete, and one reduction factor, which allows for the decrease of the fabric strength due to long-term loading, ageing and effects from handling, transport and erection. By selecting a higher reduction factor a longer design life of the membrane may be achieved.)

Along the edge the web membrane is held and reinforced by clamping strips. Due to the large membrane forces - the membrane strength corresponds approximately to a type V - and because of the corresponding size of the edge cables (max. Ø 42 mm) and the associated fittings the edge was executed as a clamped edge with a steel boltrope. The clamping section is intermittently fastened to the edge cable by sheet metal straps in short spacing. he boltrope has a threaded fitting at its end and is anchored in a tube sleeve welded to a transverse steel plate onto which the membrane is also connected at the corner by means of sheet metal straps.

Description of the environmental conditions

Situation

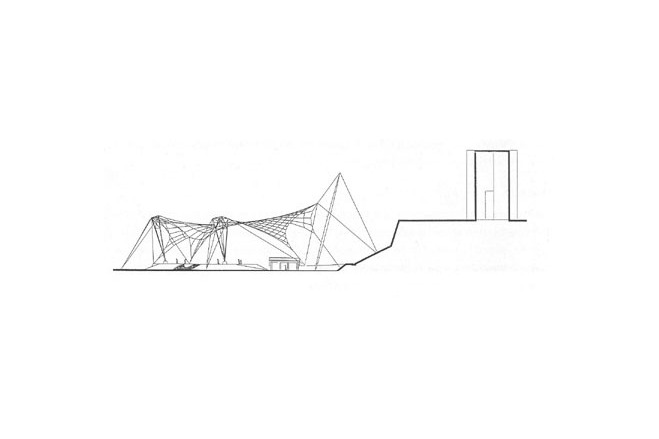

The auditorium with its semi-circular plan has the form of an amphitheatre with steeply rising seats. The entrance is from above, through a circular access path on the level of the access road in front of the theatre. The stage is hexagonal; on its left and right stage houses are erected in conventional reinforced concrete construction.

Masts

The large A-mast as a structural system is a tripod (h = 38.4m) with two intermediate guys. Two pin-supported masts joined at the top, with a dumbbell-shaped cross section (h =1.2m), consisting of two steel tubes (2 Ø 323.9 x 8.35 mm) connected by a twin web with variable height, are tied to the outside by a main stay on the axis of symmetry and also by two additional guy cables on both sides connected at intermediate points along their length. They consist of three modules and one head piece; these modules are joined by bolted flange connections for easier handling during assembly. Where the intermediate guys are connected to the masts a horizontal tie cross-bracing consisting of steel rods (Ø 24mm) joins the mast tubes. The mast base is formed by a steel ball joint (Ø 320 mm).

The head of the main mast consists of a welded steel plate assembly and circular tubes. The guy cables and other ties are either connected with fork fittings and conical sockets at the head plates or they pass through a tube sheath where they are anchored with nuts and counter nuts. To simplify transport the mast head assembly is joined with a bolted flange connection to the mast members.

The heads of the smaller v-shaped edge masts (h = 16m, tube Ø 353.9 x 6.3/7.1 mm) were developed into a space frame consisting of three tetrahedrons (3.2m x 6.0m, h = 4.4m). It consists of steel tube compression members (Ø 168.3 x 4.5 mm, Ø 159 x 3/4.5 mm, Ø 108 x 3/4 mm) and horizontal round steel tension ties (Ø 45 mm) and serves as a fixing point for two membrane tips and a ridge cable between them. To avoid bending of the mast (i.e. due to the difficulty of carrying bending moments across the spherical nodes of the space truss) two additional cables (outside Ø 26 mm, inside Ø 36 mm) were introduced, leading to the mast base. To the outside the edge masts are guyed by three cables (Ø 36 mm + 2 x Ø 19 mm). The head structure of the smaller v-shaped edge masts is connected to the lower mast tubes by a spherical space frame node. For this purpose the mast tube cross section is reduced in diameter by a welded steel cone, held at the node by a welded tubular sleeve and secured by bolts. The lower compression members of the space frame are attached to conically turned steel parts secured by bolts. The turned steel parts are fastened at the node by bolts coaxial with the member.

At the upper nodes of the head structure, which is a welded assembly of steel plates and tubes, the upper space frame struts are connected via steel plates and pins. The horizontal tension ties are either connected with fork heads and bolts or are furnished with threads, passing through a welded tube sheath and being secured there with nuts and counter nuts.

The four inner compression tubes at the head of the smaller edge masts are connected with the welded nodes by a bolted flange with a diameter equal to that of the connected tubes.

The detailing of the bases of main and edge masts is similar: Two converging tube sections penetrate each other at the base and are either welded to a transition piece made from steel plates (main masts) or connected with a bolted flange (V-shaped edge masts).The transition piece transfers the mast forces to a spherical steel bearing, whose bottom shell is fastened on the foundation with anchor bolts. A cover plate fastened with bolts onto the bottom part protects the bearing.

The steel parts of the main structural elements are galvanised and painted.

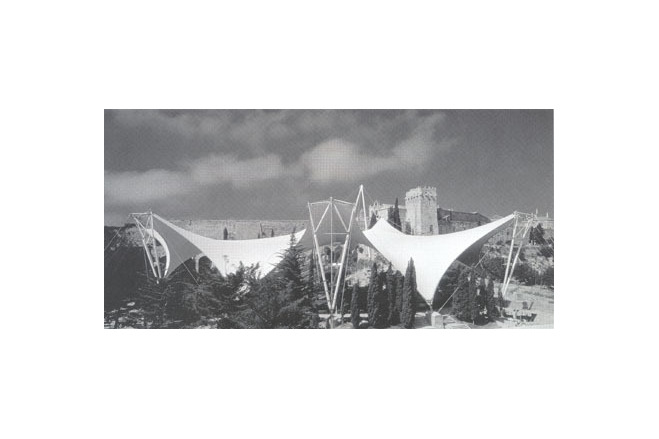

General comments, links

Design

This roof over an open-air theatre with 3000 seats situated at the edge of the old city centre of Tarragona has some special features, which distinguish it from others of its kind. It lies underneath the city walls and below a monumental tower in a natural bowl forming the amphitheatre at the foot of a steep embankment. Tower and city wall serve as backdrop for the open-air theatre, whose membrane roof with its fascinating form has become the landmark of this part of town.

The allusion of a manta ray from the sea, of which the roof form is reminiscent, emphasises the connection of the city with the Mediterranean. The view of the passing access road, the Avenida de Maria Cristina, and onto the tower and the ancient city wail remain unchanged.

The axis of symmetry of the amphitheatre and of the structural axis coincide and lead onto the monumental tower. The masts of the structure rise up high and lean toward the tower. In a common frame of reference the tip of the V-shaped main mast becomes the visor point, redirecting the view onto the tower. The structure appears to be tied in with measure and proportion between membrane roof and tower. Seen from inside the natural backdrop is emphasised by the steel tubes acting as a picture frame. At the same time the translucent roof creates a light-filled space without strong shadows, giving a feeling of openness, of being in the open.

Ropes, guy cables

The guy cables are connected adjustably with a conical socket with female thread and with two threaded extension bars at a solid round steel transom flattened above and below, which is fastened to a welded universal joint made from two crossing bearing pins. The tension ties are galvanised steel cables with cable fittings and prestressing devices with the following dimensions:

- hanger cables at the main mast Ø 52 mm,

- guy cables at the main mast Ø 52 mm + 4 x 2 Ø 26 mm, - membrane corner guys Ø 52 mm, Ø 42 mm, Ø 26 mm, edge cables Ø 42 mm to Ø 20 mm,

snow cables in membrane surface Ø 64 mm to Ø 36 mm, ring cables Ø 36 mm to Ø 19 mm.

The large edge cables, furnished with fork fittings with a built-in universal joint, are anchored together with a transverse bearing plate with turnbuckles and with the valley or ridge cable with its end socket in a welded steel corner element.

The version of the corner plate assembly without valley or ridge cable is much simpler.

Foundations

Due to the flat curve and the high loads the supports and guys of the tensile structure suffer relatively high tension or compression forces. A geological survey showed very unhomogeneous soil conditions, so that the foundation design was adjusted according to the particular situation. For tension piles and compression foundations the same pile type was used, namely steelmicropiles (injection piles of the type Ropress/Tubfix). According to ground type and load, up to 16-m long injection piles were used, for the compression piles to reach a load-bearing stratum, free of mud inclusions or for the tension piles to activate a sufficiently large earth volume to be used as ballast weight.

Assembly

The steel structure was assembled and erected within 16 days, for installation and prestressing of the membrane a further 25 days were required. The installation proved extremely difficult due to the problematic terrain conditions at the rear edge of the amphitheatre, where a mobile crane could only be used with difficulty. Only a mobile crane with a capacity of 15 t could be used, the A-shaped main mast however weighs 20 t and is positioned in an inaccessible location underneath the wall. It had to be divided into parts, assembled on the construction site and pulled up the sloping terrain and into its final position with tirfors. Scaffolding had to be erected on the slope and a chute, on which the mast was dragged with tirfors horizontally to its foundations, without loading the crane with the full mast weight.

[Soft Shells, Hans-Joachim Schock, p147, 150-152]

Auditorium roof CAMP DE MART, Tarragona, Spain

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Cable

-

Material Fabric/Foil

Polyester

-

Material coating

PVC

Main dimensions and form

Duration of use

-

Temporary or permanent structure

Temporary

-

Convertible or mobile

Convertible

-

Design lifespan in years

00-05

Involved companies

-

Architects

Studio Tensoforma

-

Contractors

Tensoforma Trading S.R.L

Editor

-

Editor

Marijke M. Mollaert