Lord's Cricket Ground

General information

-

Home page

http://www.basestructures.com/portfolio/projects-case-studies/lords-cricket-ground/

-

Location address

Westminster, London

-

Location country

United Kingdom

-

Year of construction

1987

-

Year of replacement of membrane

2005

-

Name of the client/building owner

Marylebone Cricket Club

-

Function of building

Stadia

-

Degree of enclosure

Open structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

mono-layer

-

Primary function of the tensile structure

- Rain protection

- Sun protection

Description

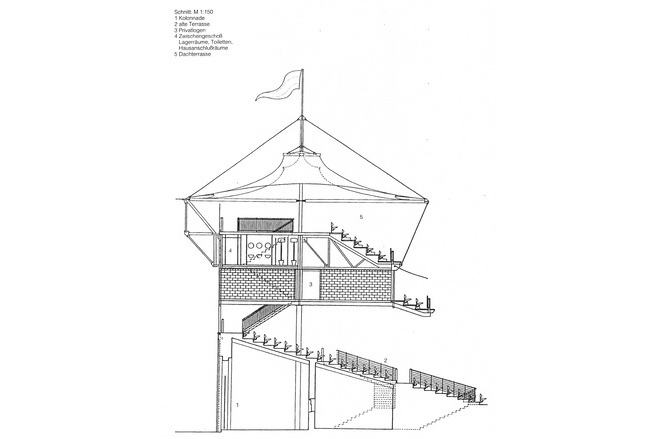

Our second major fabric structure was the Mound Stand at Lord's Cricket Ground, London 1987. This is an umbrella structure, an open-air space, evoking the atmosphere of sunny afternoons of cricket interspersed with tea in a marquee. Each layer of this building records a period in the history of building technology. The base comprises load-bearing brick arches, the next level is steel framing with concrete block infill, above that is a floor built as a steel box, and then finally one arrives under the membrane cones with masts and cables. There is a progressive sophistication and lightening of the construction floor by floor.

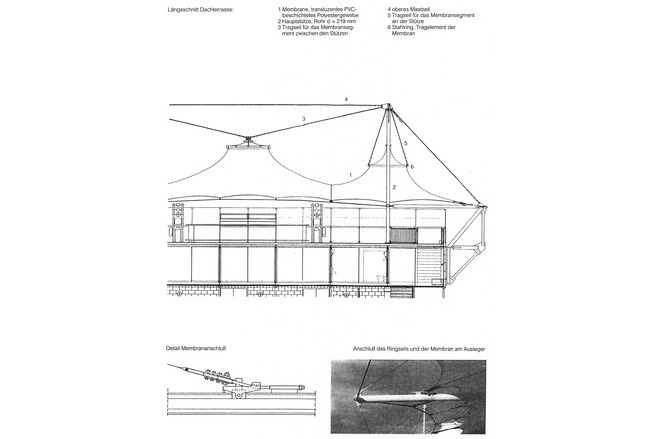

The six masts, extended from the columns below, support truncated fabric cones with bases roughly twice the width of a structural bay. Between these are a series of larger cone which sit slightly higher, generating a rhythmic pattern of major and minor peaks and troughs. The fabric is PVC coated polyester fibre in panels with clamped joints. The pick-up is made by means of a steel ring at the top of each cone which spreads the load into the material.

From each of the masts horizontal booms project forwards and backwards beyond the edge of the fabric roof. Because the masts are placed eccentricity under their load, with the side facing the cricket being heavier, no cables are required to be tied down into the public seating area where they might interfere with a view of the game. At the back graet brackets of steel tubes tie down to the plate girder rear wall of the floor below. From the extremities of the booms the edge cables are pulled into a horizontal catenary by the tension of the fabric, giving the roof its festive wavy edge.

(Michael Hopkins and Partners)

Part of the success of this structure is that it appears to float over the Mound Stand supported as it is by only 6 masts, each 18,3 m apart, with tubular steel booms reaching forward and back. From the top of the mast, cables support fabric pickup rings at column positions and at midspan. The front and rear edges of the fabric are attached in 3,66 m scallops to external boundary cables which connect to the boom ends. Valley cables pass over the fabric from the front to the rear catenary between the pick rings and pull it into shape with the curvature needed in these areas. The front booms are tied down by cables to the front of the upper promenade while the rear frames resist transverse forces from the wind and out-of-balance loading. They must also resist the overall force towards the pitch caused by the longitudinal tension in the fabric passing around the curve.

The ends of the roof are held out y booms radiating from the end masts and tied together at their ends. Thus all the booms are connected around the perimeter. Lazy cables from the mast heads support the ends of the booms if the fabric should fail. The longitudinal tension in the roof is resisted by end frames which cantilever up from the ends of the spine beam.

All the steel work joints are pinned apart from those at the base of the masts. This allows the structure to change its geometry and so to maintain equilibrium under changing load. The cables linking the tops of the masts continue down to the end frames and resist out-of-balance loads between bays and also give an alternative load path should the fabric or its supporting cables fail.

The fabric is PVC coated polyester treated with PVDF on the upper surface to improve durability. The roof came as seven panels, one for each 18,3 m bay and two end panels. They were joinedby aluminium clamp plates. The final erection was carried out by fixing the boundary ponts and then pulling the rings up to the correct level. All the cables and boundary tubes were provided with adjustment as were most of the fabric attachement points. A total of 130 different cutting patterns were calculated for this roof to account for the slightly irregular plan shape of the Mound Stand.

(Brian Forster, Ove Arup & Partners)

[Membrane Designs and Structures in the World, Kazuo Ishii, p56, 59]

Description of the environmental conditions

In 2005

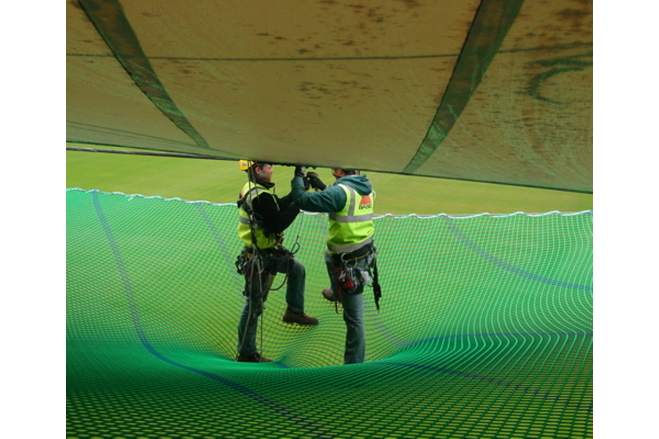

After 19 years in service the original membrane looked dirty as the surface treatments in those days were based on acrylics. Since the Chelsea/Marlyborne area contains very exclusive boroughs, there was no possibility to obtain a new building permit, the original structure had therefore to be rebuilt strictly identical to the original one.

> Dismantled in Dec. 2005 in ONE DAY

> Re installed in Dec. 2005 in SEVEN DAYS

• Removal of the original iconic Mound Stand Canopy

• Replication and installation of replacement canopy

• New fabric specification ensures longer life span than original

• Review and redesign of fixtures and fittings to bring up to current design and best practice standards

• Working Platform Nets enable project completion below budget and ahead of schedule

• Old canopy recycled at specialist facility

New material PRECONTRAINT 1002 T2

The original membrane was recycled with the TEXYLOOP TECHNOLOGY

General comments, links

www.hopkins.co.uk/projects/3/94/

www.armadilloengineering.com/portfolio.asp

Teil 9/21: Mound Tribüne, Lord's Cricket Ground

Hopkins, the work of Michael Hopkins & Partners

Verso un processo integrato

Stade de cricket a Marylebone, Londres

Mound Stand, Lord's Cricket Ground, London

Michael Hopkins Architects. Projects and realisations

Lord's Cricket Ground, Mound Stand

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Material Fabric/Foil

Trevira high tenacity polyester

-

Material coating

PVC

Main dimensions and form

-

Covered surface (m2)

1380

-

Total length (m)

20

-

Form single element

Anticlastic

Duration of use

-

Temporary or permanent structure

Permanent

-

Design lifespan in years

31-..

Involved companies

-

Architects

Michael Hopkins & Partners

-

Contractors

Koit High-Tex GmbH

-

Suppliers

SERGE FERRARI

Editor

-

Editor

Marijke M. Mollaert