Schlumberger Cambridge Research Centre

General information

-

Location address

Madingly Road Cambridge, Cambridgeshire

-

Location country

United Kingdom

-

Year of construction

1984

-

Name of the client/building owner

Schlumberger Cambridge Research Ltd., Cambridge

-

Function of building

Laboratories & research centres

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

mono-layer

Description

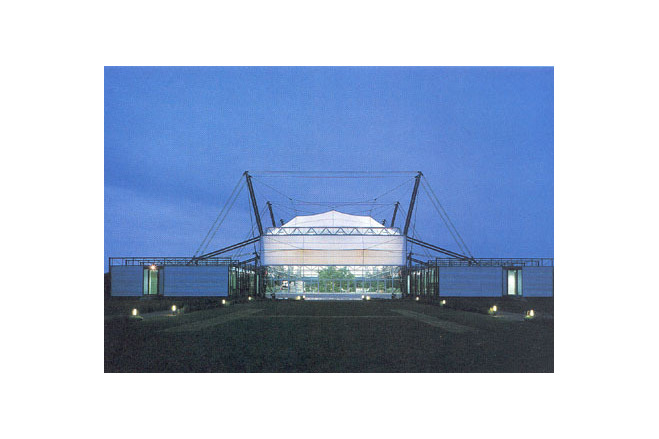

The research building for Schlumberger in Cambridge, England, completed in 1984, represents the first large-scale example of the use of a Teflon coated, glass-fibre membrane in the UK. Although the setting of the building is far from urban, the project contributed to the development of tensile architecture by successfully demonstrating how a membrane envelope could be combined with more conventional, rectilinear construction. The brief required a facility for research into aspects of oil exploration, to include a drilling test station, laboratories, offices and staff facilities. The building also had to provide opportunities for contact between scientist and research staff and provide spaces for meetings with university personnel.

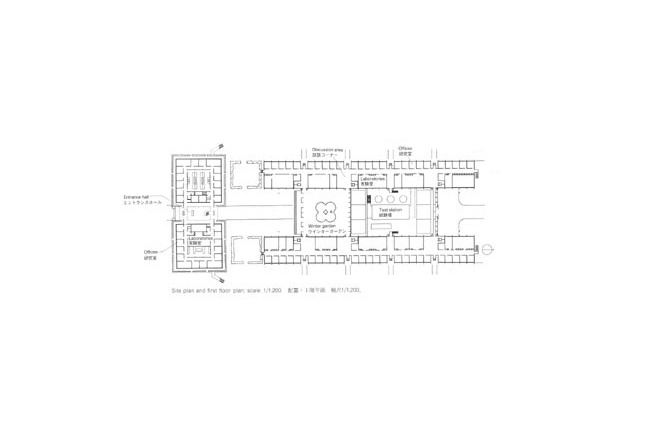

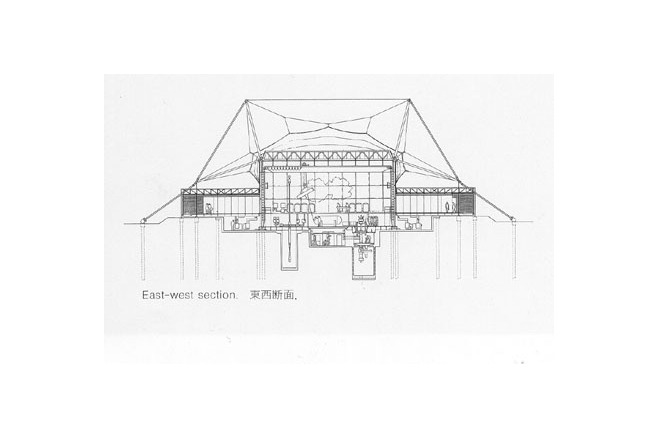

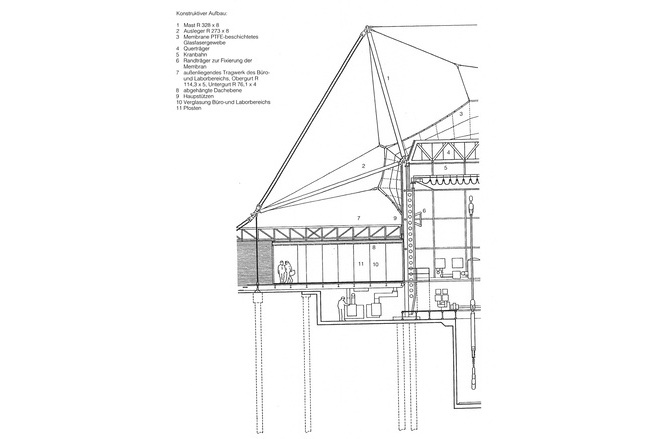

Through a clear separation of the facilities into those serving largescale use and those requiring smaller, subdivided spaces, a simple and logical plan form has been produced. Two single-story wings running north-south are seperated by a 24 m wide space which is covered by the single-skin membrane. The central space is divided into three bays, two of which house the drilling test station. The drilling rig requires only basic shelter and is thus suitable catered for by the large space enclosed by the membrane roof. The third bay is used for a winter garden where the staff restaurant and library are located. The restaurant and library areas, whiich require a greater degree of environmental control, benefit from being flanked by the single-storey offices and research facilities, which act as tempered buffer zones. Both spaces underr the membrane roof benefit from the natural daylighting that permeates the membrane fabric, which has a 13 % translucency. In addition, the prismatic trusses that span the central space and separate the membranes are glazed, affording views of the sky and letting a proportion of direct sunlight into the centre of the deep plan.

The combination of direct and diffuse sunlight gives the central spaces a unique quality of light that would be difficult to achieve if more conventional roof had been employed. At night these spaces are lit by uplighters, fixed to the internal steel structure, using the surface of the membrane to reflect light down onto the spaces below.

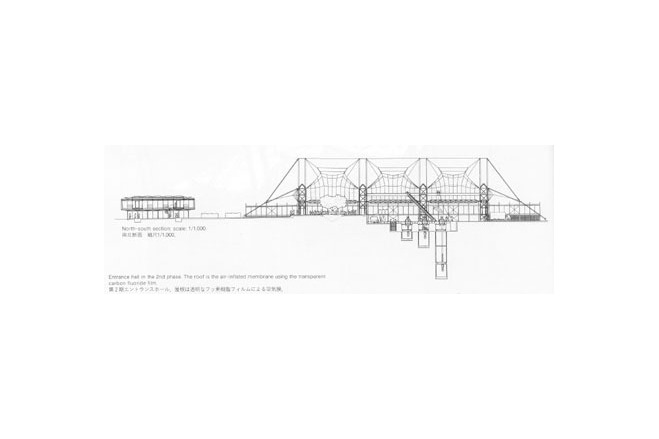

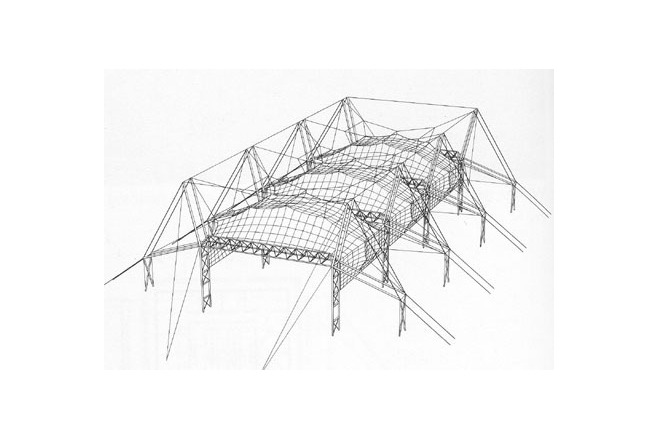

Roof structure

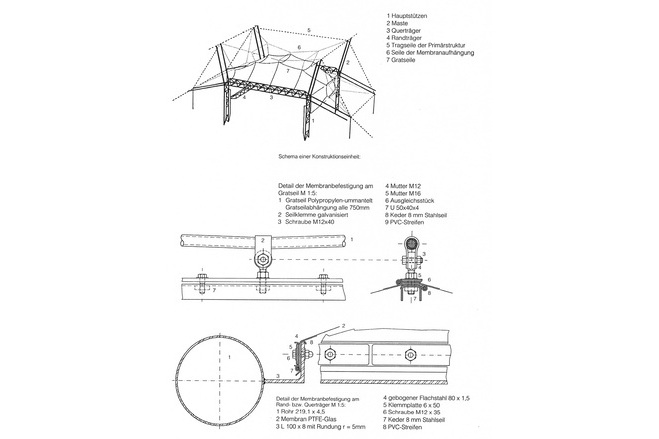

The seperation of the roof membrane into three main sections corrsponds to the 18 x 24 m structural bays. In addition individual tensioned fabric panels are employed at both ends of the building. In each situation the boundary of the membrane is clamped to a rectilinear framework, which is seperated from the main structure with glazed infill panels. The suspension and tensioning of the membrane is achieved fron the outside by means of steel cables, hung from eight pairs of tubular steel masts. These masts are supported on steel lattice frames 2,4 m wide and 19,2 m apart. The frames are linked by 1,5 m deep by 24 m long prismatic trusses forming portals that span the central spaces. Aerial booms, connected to the main masts by tension rods, complete the exterenal framework that holds the membrane in its required doubly curved shape. Once the membrane had been installed and clamped in place, it was pre-stressed by shortening the links betweenn each ridge cable and its corresponding aerial cable.

[Tensile Architecture in the Urban Context, Rudi Scheuermann & Keith Boxer, p114, 116]

Description of the environmental conditions

General comments, links

The project has won several awards: Financial Times Awards Joint Winner - 1985, Structural Steel Design Award Commendation - 1988, RIBA Award Winning Buildings - 1988, Civic Trust Award Winning Buildings -1988

Teil 9/21: Schlumberger Forschungszentrum

Centre de Recherche Schlumberger

Schlumberger Cambridge Research Centre

Michael Hopkins and Partners

High Tech Architecture

Hopkins, the work of Michael Hopkins & Partners

Verso un processo integrato

Toiles composites pour architecture légère

Research Facilities for Schlumberger, Cambridge

Schlumberger Cambridege Research Centre

Schlumberger Cambridge Research Center

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Material Fabric/Foil

Fiberglass

-

Material coating

PTFE

Main dimensions and form

-

Covered surface (m2)

2160

-

Total length (m)

18

-

Total width (m)

24

-

Form single element

Anticlastic

Duration of use

-

Temporary or permanent structure

Permanent

-

Design lifespan in years

31-..

Involved companies

-

Architects

Michael Hopkins & Partners

-

Engineers

Arup

-

Contractors

Stromeyer Ingenieurbau GmbH

-

Suppliers

Verseidag-Indutex GmbH

Editor

-

Editor

Marijke Mollaert