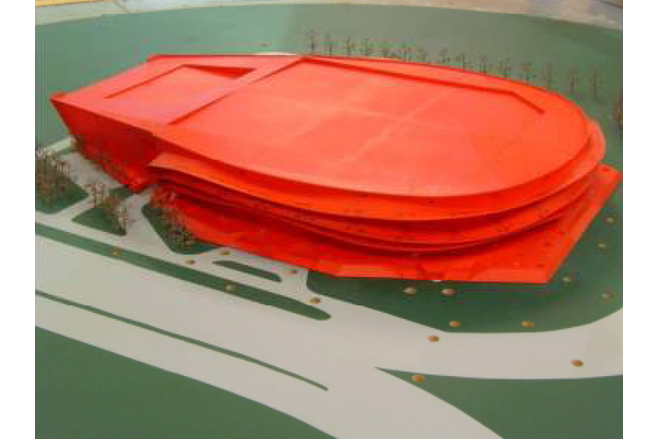

Arena of Baku

General information

-

Home page

http://tensileevolution.com/baku

-

Location address

Baku

-

Location country

Azerbaijan

-

Year of construction

2015

-

Name of the client/building owner

Pasha Insaat, Baku, Azerbaijan

-

Function of building

Sport

-

Degree of enclosure

Open structure

-

Number of layers

mono-layer

-

Type of application of the membrane

attached

-

Primary function of the tensile structure

- Daylight gains

- Space defining elements

- Sun protection

Description

The use of tensile surface structures as an additional building envelope has reached an ever growing acceptance in architectural and engineering offices in recent years. They are used as visual, thermal or acoustic filters and create fluid spaces that mediate between the interior and exterior. Creative planners are thus able to apply membranes not just as temporary or permanent gigantic billboards, which is the most common use of textile fabrics in modern architecture.

The history of textile ribbons starts with the long tradition of textile canopies as independent elements that offer shade and rain protection. It is the combination of this old idea with the modern technology of textile envelopes that introduces new options to the field of architectural creation. Once the structural challenge has been solved, it becomes possible to combine shade and transparency in a fascinating new way. The building can be partly revealed and partly covered; sun-rays can be deflected, reflected, diffused or filtered with the help of undulating textile ribbons; and last but not least, the building´s appearance at night can be highlighted through sophisticated led illumination systems either from within or from behind the ribbon´s structure.

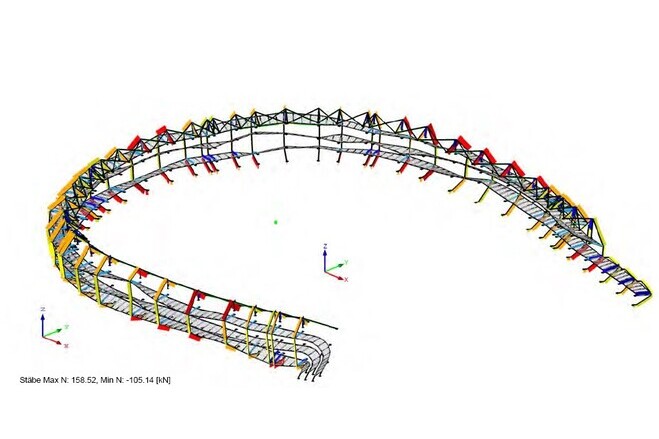

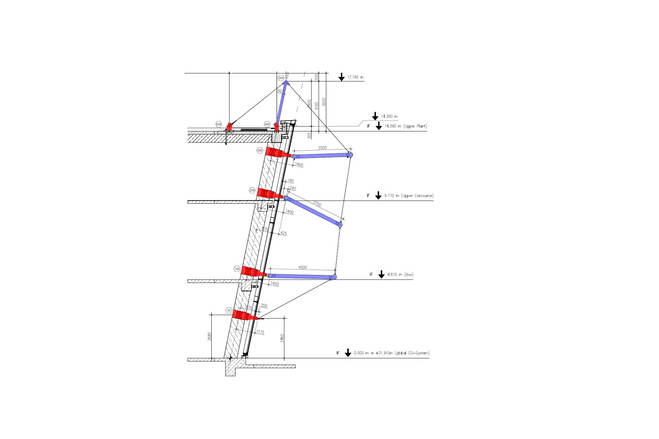

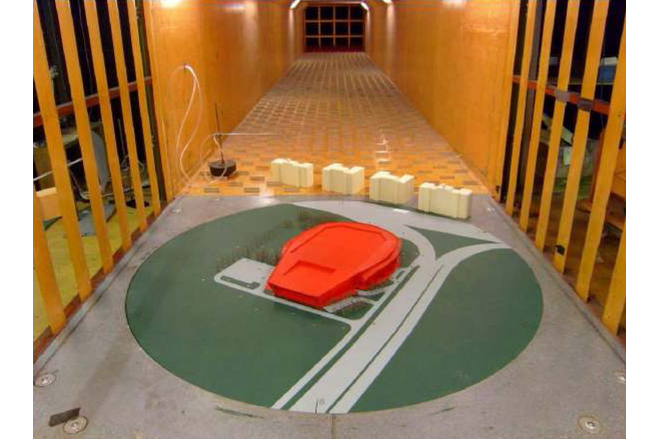

The National Gymnastics Arena in Baku is a key part of Azerbaijan´s bid for the 2024 Summer Olympic Games and Broadway Malyan, an international architectural firm, has been selected to design the competition level center for rhythmic and artistic gymnastics. IF-Group, a well known German engineering company whose roots lie in the design and calculation of tensile surface structures, participated from the beginning in the elaboration of workshop drawings and the structural calculation of the inclined curtain wall of the new center. In a second phase, for the approved final design, IF-Group designed the supporting steel ladder of the textile ribbon structure and the bracketry fixed to the inclined concrete pillars behind the glazed façade. Its contribution to the new building also included form finding of the textile membrane, cutting pattern generation and the method statement of the complete structure.

The first design of the Textile Ribbon Façade consisted of three horizontal ribbons in the colour of the Azerbaijan flag. As well as the functional task of controlling solar radiation gains, the idea was inspired by the ribbons used in rhythmic gymnastics exercises. However, the chosen coloured bands would have been nearly opaque because of the reduced translucency of coloured PVC coated polyester. In order to achieve a powerful nocturnal lighting together with a diffused solar radiation, therefore it was decided to use a plain white membrane Type II with a relatively high translucency of about 10%.

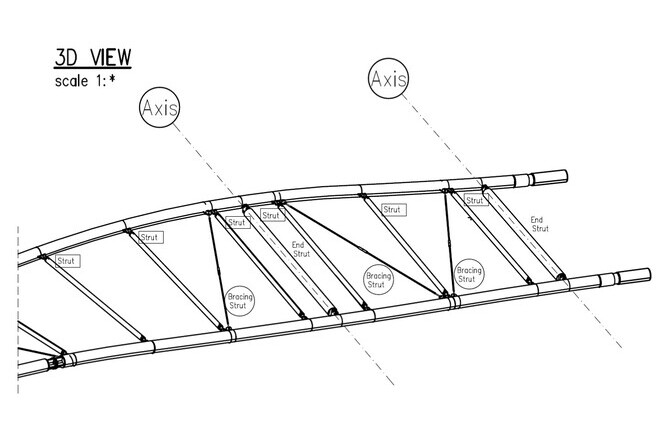

The steel structure of the Textile Ribbon Façade had to be suspended from the roof top. For this purpose, inclined struts with their tie-down rods were located above the primary steel mullions of the glazed façade.

Once the prefabricated ladder sections of the textile ribbons were in place the membranes could be fixed and tensioned from either side. The result is a continuous band of textile that completely covers the undulating steel structure. The process of fabrication of this complex three-dimensional form, made of circular hollow sections, was a challenge and required IF-group to send an engineer to the Turkish steel contractor in order to oversee the bending and welding process. Before transporting the elements to Baku, the final assembly process also had to be monitored. The building, including illumination, was finished in 2014.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Type (code)

FERRARI 1002 S

-

Material Fabric/Foil

Polyester

-

Material coating

PVC

Main dimensions and form

-

Covered surface (m2)

7700

Duration of use

-

Temporary or permanent structure

Permanent

-

Design lifespan in years

21-30

Involved companies

-

Architects

Broadway Malyan Limited

-

Engineers

IF Ingenieurgemeinschaft Flächentragwerke

-

Contractors

Asma-Germe

-

Suppliers

SERGE FERRARI

Editor

-

Editor

Marijke M. Mollaert