Mobile Building System for Exibitions 'AIC-Tensoforma'

General information

-

Home page

http://www.tensoline.com

-

Location address

Bergamo

-

Location country

Italy

-

Year of construction

1987

-

Name of the client/building owner

Tensoforma Trading, Bergamo

-

Function of building

Exhibition

-

Degree of enclosure

Hybrid structure

-

Climatic zone

Mediterranean - mild winters, dry hot summers

Description

Membrane structures, including tents,usually have guys, which carry the tensile forces from the roof membrane down into theground; anyone who has everstumbled over tent chords and pegs on a campground wiII know this. If a modular, additive building system is desired, the task is especially troublesome.The membrane building system described here manages without external guys.

Design

Aesthetics and style were of great importance in the design.The architects see their modular arch structures as a modern analogy of Romanesque cross vaults. However that may be the simple, classical lines and consistent technical detailing of these structures fit into almost any surroundings.

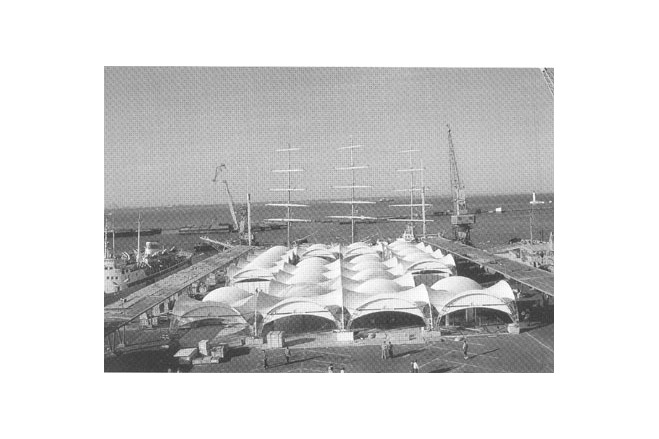

At the beginning there was the self-imposed task of developing a building system, which was mobile, i.e. capable of being erected and dismantled with simple means, and which was modular, i.e. capable of being added to in two directions. Above it the membrane roof was to be square in plan (10m x 10m). Later it was developed into a modular system with square, hexagonal and triangular modules.

Form

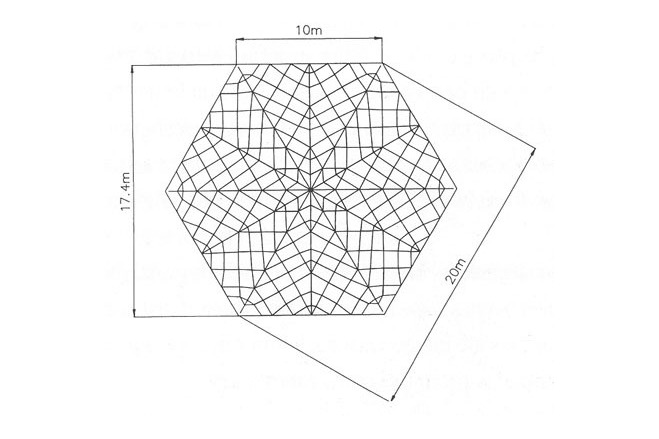

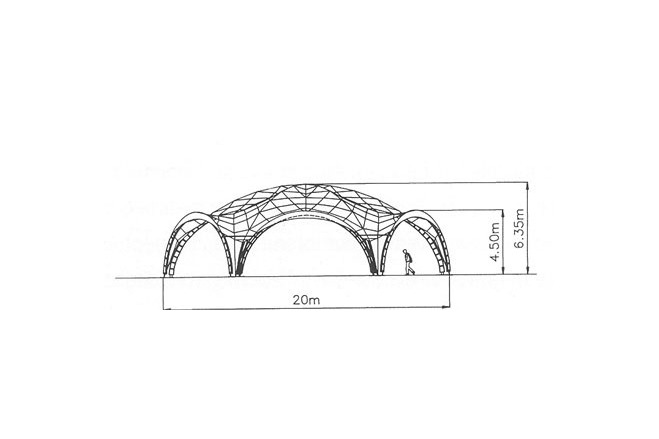

The system includes three basic modules, square, hexagonal and triangularwhich can be set up alone or in combination. Numerous combinations of the three basic modules are possi ble, as the edge arches have equal dimensions.The versions for short-term and permanent applications have the same standard dimensions.

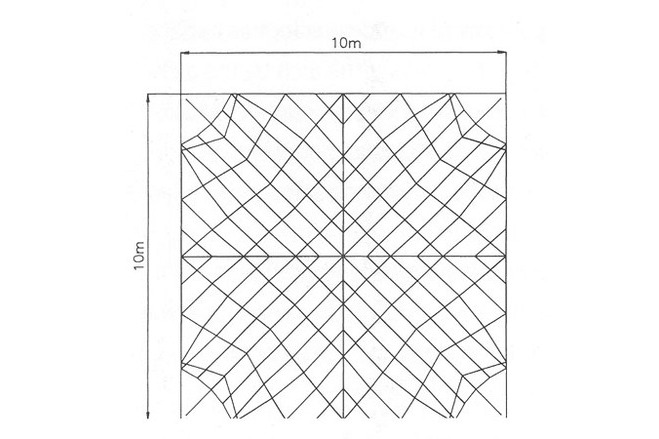

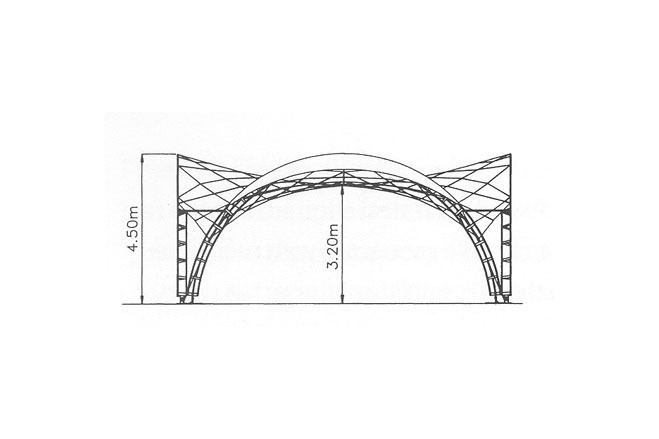

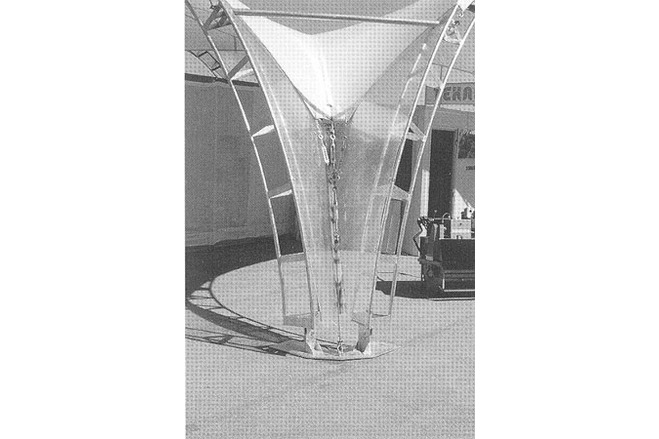

The square module has a saddle-shaped roof membrane over four circular edge arches with valley cables diagonal in plan. Geometrically the form can also be interpreted as a section of a vertical square prism with two HP surfaces penetrating each other at a right angle. Four semi- circular arches in this case replace the parabola-shaped edge arches of the HP surface.

The triangular module is set up similarly. The form of the hexagonal module is a composite surface of six saddle shapes between vertical edge arches and three radial inner arches.

Structure

Depending on the type of application the four semi-circulars edge arches are three-chord trusses with curved round steel diagonals or a three-chord Vierendeel arch with gusset plates, the latter being simple to make, but it is stressed in bending and therefore heavier. The arches are connected by bolts at the apex and at the quarter points and pin-connected at the arch base with a steel-base plate, where also the diagonal valley cables are anchored. The temporary version is anchored at the ground with earth nails and the permanent version with rawlplugs or resin anchors in concrete foundations or a ground slab. The temporary (summer) version is only designed for wind load;while the ones for long-term application are designed for wind and snow loads.

Square module

The square modules available in four sizes (6 x 6, 8 x 8, 10 x 10 and 12 x 12 m) consist of a roof skin of PVC-coated polyester fabric over four vertical steel edge arches with two diagonal valley cables as membrane reinforcement.The arches are connected with each other by four diagonal struts,fixed at 2/3 of the arch height, so that the stability of the arch is not dependent of the membrane. In the plane of the arch the structure works as a two-pin arch, perpendicular to it as a space structure with bending and torsion. The building is braced in the plane of theThe building is braced in the plane of the arch by the arch itself, and perpendicularly to it by tubular members in tension or compression connected at half-height across the corner between adjacent arches.Two valley cables diagonal in plan transfer the wind uplift forces directly to the base-plates, without loading the arch.

Hexagonal module

The elements of the hexagonal module have an edge length of 1O m; each module covers a base area of 260 M2 Three radial and six edge arches carry the membrane.The edge arches are joined with each other by six diagonal struts, whereby the stability of the arch is maintained without use of the membrane.

[Soft Shells, Hans-Joachim Schock, p160-163]

Description of the environmental conditions

General comments, links

Development

In the seventies the office of AIC in Stuttgart developed a membrane building system with four braced arches carrying a roof membrane over a square plan.This system was taken over under license by Studio Tensoforma, an Italian planning office for membrane structures, and devel- oped into an exhibition building system in co-operation with the AIC. It offers an installation floor, inside drainage as well as planar and curved space enclosing membrane walls. Marketed bytensoforma Trading, it was used successfully on numerous sites in Italy, France, Russia and Spain.As required for a building system, all essential aspects of storage,transport and erection were optimised in a long-time development and in the course of various project applications.

[Soft Shells, Hans-Joachim Schock, p160-163]

Mobile Building System for Exibitions 'AIC-Tensoforma'

Tensostrutture modulari ad archi

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Foil

-

Material Fabric/Foil

Polyester

-

Material coating

PVC

Main dimensions and form

-

Form single element

Anticlastic

Duration of use

-

Temporary or permanent structure

Permanent

-

Convertible or mobile

Convertible and mobile

-

Design lifespan in years

06-10

Involved companies

-

Architects

AIC Architekten und Ingenieure Coop.

Studio Tensoforma

-

Engineers

AIC Architekten und Ingenieure Coop.

-

Contractors

Tensoforma Trading S.R.L

Editor

-

Editor

Marijke M. Mollaert