Hamlet Collective Residence

General information

-

Location address

Tokyo

-

Location country

Japan

-

Year of construction

1989

-

Name of the client/building owner

Hiroshi Omi

-

Function of building

FLats & appartements

-

Climatic zone

Temperate - cold winters and mild summers

Description

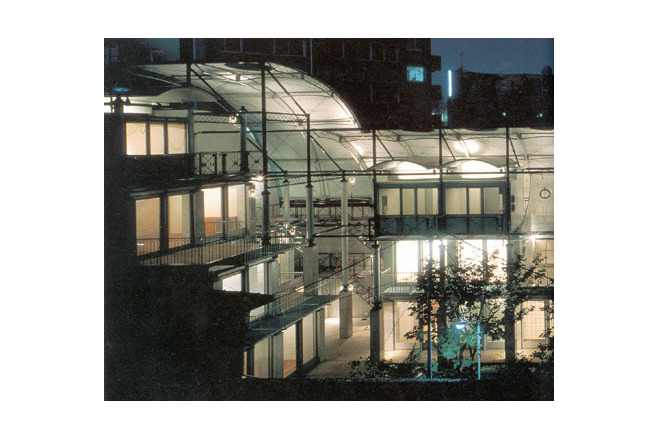

Doesn't a membrane roof seems to possess a mysterious power? Imagine that there were several buildings : large and small, standing independently and in dissarray. Once covered by a membrane roof, they could appear as components of a single building and compliment each other.

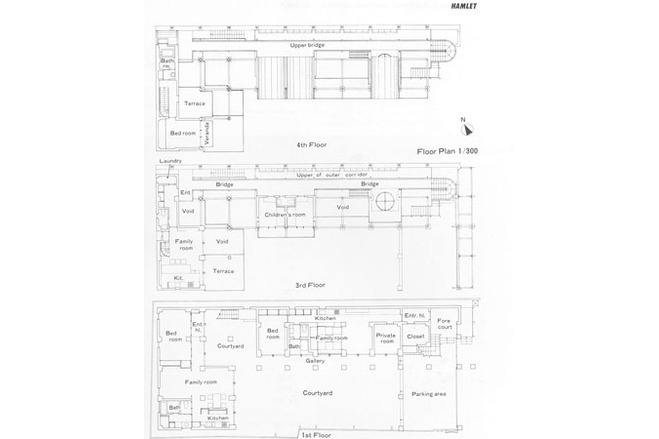

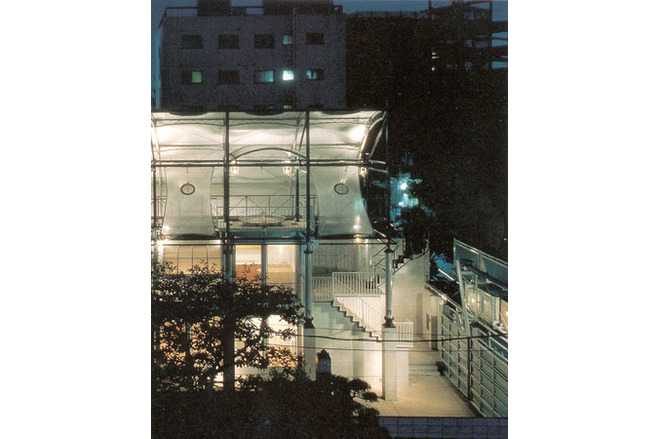

<HAMLET> is this sort of a building. It houses three generations of people from four families. On the first floor are the residences of one parent and her youngest son and his family. On the second floor dwells the eldest daughter and her family. On the third and fourth floors live the eldest son and his family. Each portion of this family's residence is seperated from the others. In this sense they are independent from each other. On the other hand, their children's rooms are positioned, one upon the other, so as to appear as a children's tower from outside.

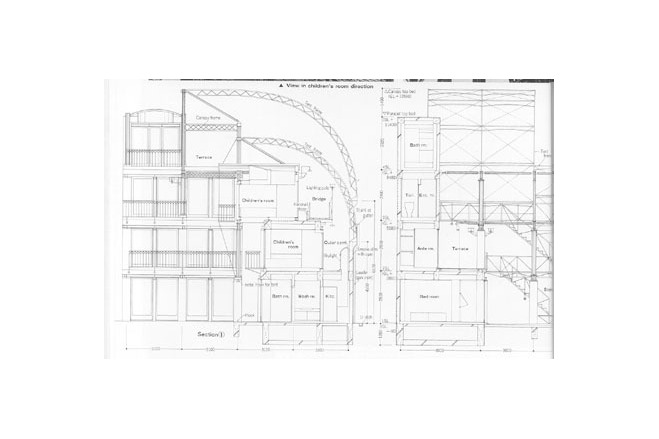

The whole building is covered by a semi-vaulted membrane roof. Each floor has its own additional membrane roof. From the entrance, it all appears as one roofed surface. This building has a rather erratic construction, but it also possessess a quality of organization situated under one membrane roof.

In this structure two kinds of tent-like coverings are used. One is a half-vaulted roof which covers the whole building; the other is a tensed membrane which is used for privacy and shade. The upper roof is made of a PTFE-coated glass fiber membrane with the same tension introduction method that was used on membrane material in the <ROTUNDA>. To make the edge of membrane roof look sharp, it was fastened to a flat, aluminium bar. This bar was immidaitely fastened with bolts to steel angle frames which had several holes incorporated for future tension adjustment.

The openings in the upper roof are windholes, designed to alleviate wind pressure. They have been reinforced by Kevlar ropes to prevent tearing from tension. Blinds and shades are made opolyester fiber fabric. Originally they were intended to be spread out in a flat position. In such a position, it was very difficult to overcome fluttering. Eventually, a three dimensional tension structure with a curved surface was developed. This was the simplest solution: to elevate the central portions of several membrane sections.

[Membrane Structure in Japan, Kazuo Ishii, p302-303]

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Cable

-

Material Fabric/Foil

Fiberglass

-

Material coating

PTFE

Main dimensions and form

Duration of use

-

Temporary or permanent structure

Temporary

-

Convertible or mobile

Convertible

-

Design lifespan in years

00-05

Involved companies

-

Architects

Riken Yamamoto and Field Shop

-

Engineers

SIGRO Engineering Association

-

Contractors

Taiyo Kogyo Corporation

Editor

-

Editor

Marijke M. Mollaert