Gottlieb-Daimler-Stadium

General information

-

Location address

Mercedesstrasse Stuttgart

-

Location country

Germany

-

Year of construction

1993

-

Name of the client/building owner

City of Stuttgart (Landeshauptstadt Suttgart)

-

Function of building

Stadia

-

Degree of enclosure

Open structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

mono-layer

-

Type of application of the membrane

covering

-

Primary function of the tensile structure

- Rain protection

- Space defining elements

- Sun protection

Description

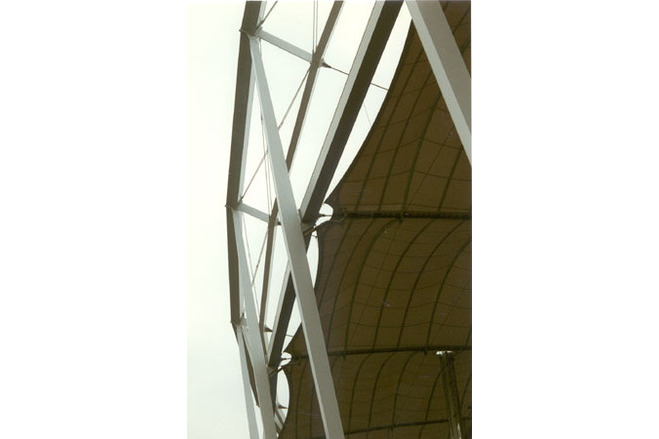

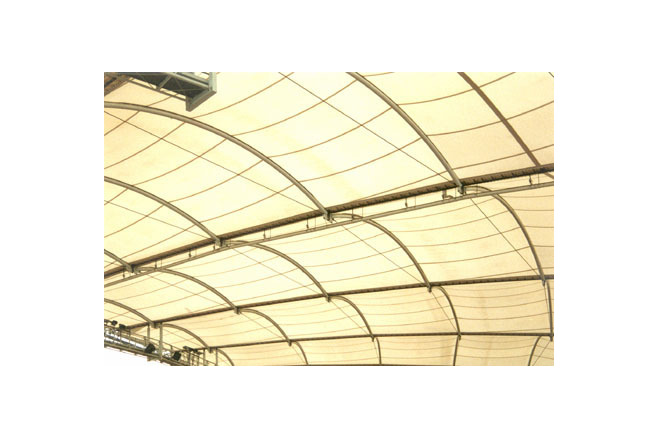

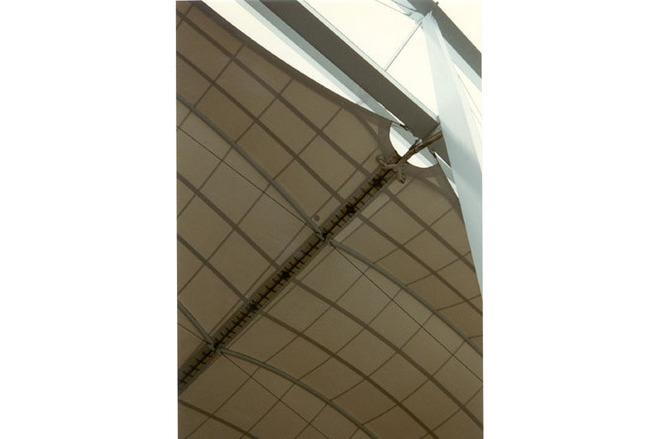

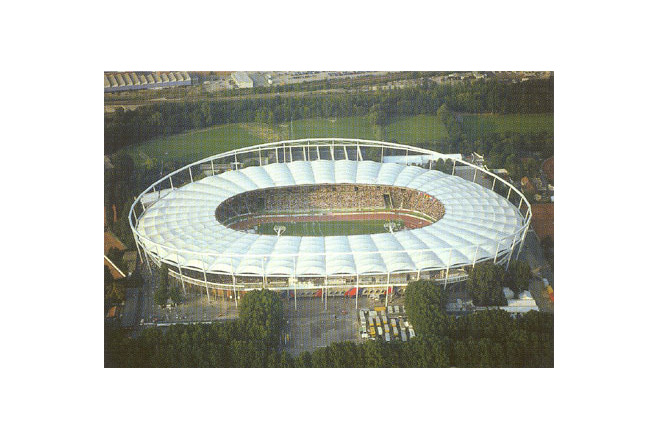

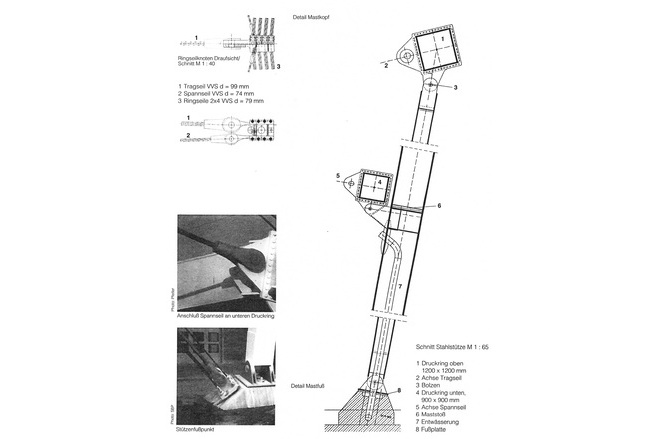

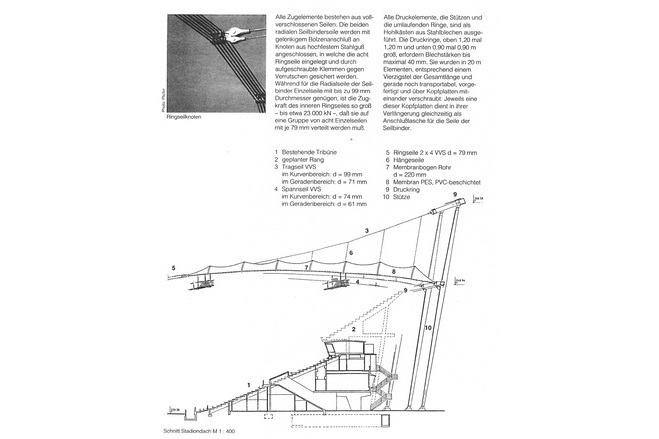

In August 1993 the Field and Track World Championships were held at the Gottlieb-Daimler Stadium in Stuttgart. For this event Schlaich and Bergermann together with the architects H. Siegel und Partner and Weidleplan were comissioned to design a roof to completely cover the grandstands. The task was challenging. Time and money were strictly limited, and it was required to interfere as little as possible with the continuied functioning of the sports venue. The site near the river was composed of poor soil, but the conventional response of driving piled foundations was ruled out because of concern over the purity of the groundwater supplying the famous mineral water wells in the locality. The partnership chose to use a spoked-wheel type of structure because it was ideally suited to the situation, being entirely self-contained from a structural point of view and thus transferring only vertical loads to the ground. As a result, only small spread footings were needed at the bases of the columns, and there was no need for back-stays or ties which would have required bulky anchor blocks or tension pile anchorages. The sparse structural system of masts and cables was economical and simply erected. Within 18 months, the partnership had designed the largest membrane roof in Europe and construction had been completed on budget and on time.The outer edge of the roof is elliptical in plan with main axes of 280 and 200 metres and consists of two steel box compression rings supported by 40 steel box columns. The rings undulate in elevation to follow the varying heights of the grandstands. A steel-cable tension ring is suspended above the inner edges of the grandstands with 40 radial cable-girders stressed like spokes between the inner tension ring and the outer compression rings.The cable-girders consist of upper and lower cables which are connected and prestressed against each other by vertical suspender cables. The tension in the upper cables increases under snow load, while that in the lower cables increases under wind suction (uplift). The width of the roof between the outer and the inner rings is a constant 58 metres. The roof is divided into 40 panels, each bounded by two adjacent lower radial cables, the lower compression ring, and the inner cable. The total area of membrane is 34000 square metres. Each panel is supported by seven parallel tied arches running in the circumferential direction and spanning between the lower cables of adjacent cable-girders.The columns and compression rings were first erected with the aid of cranes. The tension cable ring, consisting of eight locked coil ropes, was then laid out on the ground in the stadium and lifted into position using the (extended) radial cables of the cable girders. The tied arches could then be installed and the membrane laid over them. No temporary supports were needed for this process and there was no interruption to the scheduled sports activities in the stadium.

Description of the environmental conditions

General comments, links

Die Membranüberdachung für das Gottlieb-Daimler-Stadion

Stadium in Stuttgart, Stahlbau-Konstruktionen

Am Neckar

The new Cable-membrane Structure for the Neckarstadium Roof in Stuttgart

The Art of Structural Engineering: The Work of Jörg Schlaich and his Team

Teil 9/21: Stadiondach Gottlieb-Daimler-Stadion, Stuttgart

Projects / References: Gottlieb-Daimler Stadium Stuttgart

Gottlieb-Daimler Stadium

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Hybrid

-

Material Fabric/Foil

Polyester

-

Material coating

PVC

Main dimensions and form

-

Covered surface (m2)

34000

-

Total length (m)

58

Duration of use

-

Temporary or permanent structure

Permanent

-

Design lifespan in years

31-..

Involved companies

-

Architects

schlaich bergermann partner

Siegel und Partner

Weidleplan

-

Engineers

schlaich bergermann partner

-

Contractors

Koit High-Tex GmbH

Pfeifer Seil- und Hebetechnik GMBH

Editor

-

Editor

Marijke Mollaert