Designer Outlet Village, Ashford - modification works & replacement of the membrane

General information

-

Home page

https://www.architen.com/articles/modifying-an-existing-fabric-structure/

-

Location address

Ashford, Kent

-

Location country

United Kingdom

-

Year of construction

1996

-

Year of replacement of membrane

2014

-

Name of the client/building owner

The Ashford Investor

-

Function of building

Shops and stores

-

Degree of enclosure

Open structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

mono-layer

-

Type of application of the membrane

covering

Description

Just like any piece of architecture, tensile fabric structures are built to meet a need at the time of construction, but what happens if the use of the building changes? Or an extension is built? Or a new owner wants to update the design?

Adapting and changing existing fabric structures is becoming more common as the lifespan of technical fabrics increases but it is a complicated process. Often integral to the stability of the canopy, fabric panels cannot be cut out or changed without an experienced team carrying out a full assessment of the impact on the wider membrane structure. So when the chance to modify one of our largest tensile fabric canopies arose, we jumped at the chance to be involved.

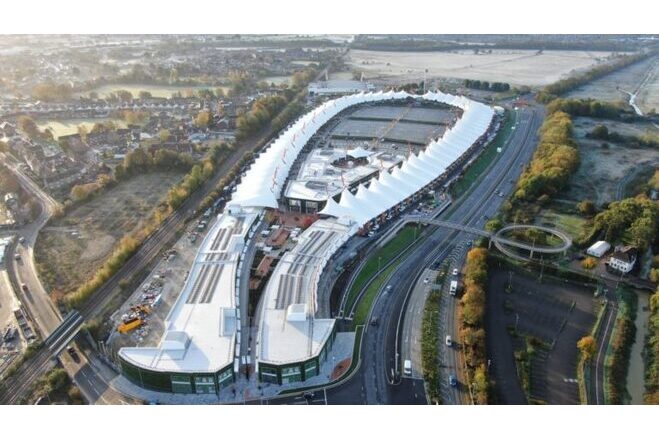

Originally built in the late 1990s and designed by Richard Rogers Partnership, the canopy at Ashford Designer Outlet is a true tensile canopy. The original teardrop shape is created by a series of tensile fabric panels, large and small steel masts and a network of boundary, tie back and hanger cables which all work together to ensure a stable structure. The removal of any one area would have huge implications for the rest of the membrane canopy.

In 2017 owners McArthur Glen embarked on the construction of a brand new extension. However, the new mall buildings clashed with the existing food court and it was clear that the area of canopy over the food court would need to be removed.

A challenging procedure

Using computer modelling software to analyse the existing canopy and the new form proposed by the project design team, various scenarios could be virtually played out to see how the membrane would behave. But once settled on an achievable design, the reality of removing a large portion of the canopy, whilst keeping the retained fabric membrane roof both intact and structurally stable through installation and beyond, was a challenge. As we had built the original canopy 18 years before, McArthur Glen and contractors McLaren Construction returned to Architen Landrell to draw on our extensive experience and long history with the site.

With design and installation teams working hand in hand, significant analysis was carried out during the design stage to establish the safest way to stabilise the structure, dismantle the old canopy and install the new one. Working to the highest safety standards, our highly experienced installation team used temporary rigging to hold the canopy in position whilst the food court area was dismantled. Continuous testing was carried out on site during the installation period to ensure that the temporary works were performing and that the remaining portion of the canopy was behaving as anticipated.

Once the food court canopy was removed, temporary rigging remained in place until the new canopy section was attached to the existing membrane and to the newly installed support structure. Only when the newly configured structure was determined to be performing was the temporary rigging removed.

The modifications have breathed new life into the tensile fabric canopy and integrated it into the current shopping centre design seamlessly showing that fabric architecture can successfully evolve and grow with the surrounding buildings!

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Material Fabric/Foil

VALMEX MEHATOP F1 FR 1000

Main dimensions and form

-

Covered surface (m2)

35000

Duration of use

-

Temporary or permanent structure

Permanent

-

Design lifespan in years

31-..

Involved companies

-

Architects

Chapman Tayler

-

Engineers

Tensys

-

Contractors

ARCHITEN LANDRELL

-

Suppliers

Mehler Texnologies

Editor

-

Editor

Evi Corne