Haj Terminal of the Jeddah International Airport

General information

-

Location address

Jeddah

-

Location country

Saudi arabia

-

Year of construction

1982

-

Function of building

Airports

-

Degree of enclosure

Open structure

-

Climatic zone

Tropical - hot and wet all year

-

Number of layers

mono-layer

Description

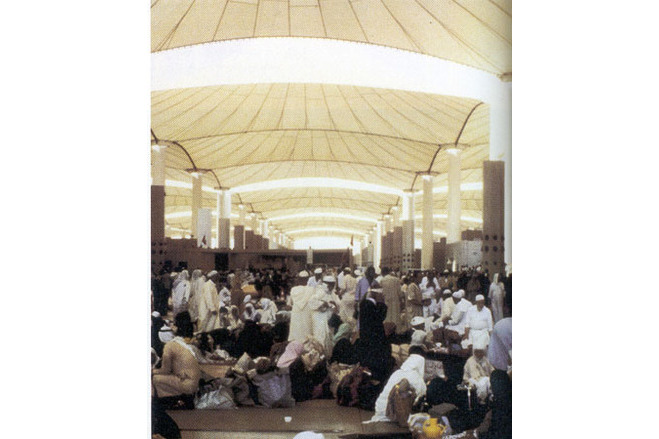

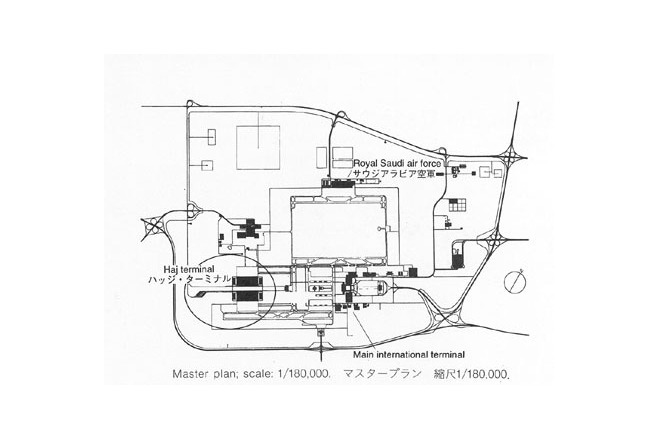

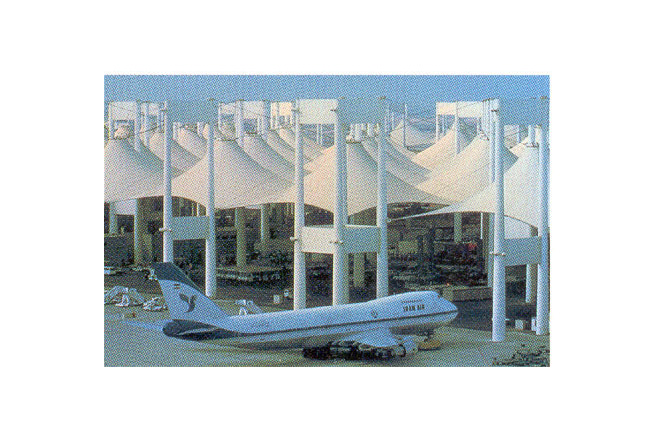

In 1977 SOM (Skidmore Owens & Merril, Architects and Engineers) was commissioned by the government of Saudi Arabia to design a terminal at the International Airport in Jeddah to serve the pilgrims (Hajis) to Mecca during the annual Moslem pilgrimage (Haj). 80000 people a day had to be accomodated in transition between busses and airplanes. To protect people against the heat of the desert sun 440000 m² of space had to be covered. An enclosed building was too expensive. A roof had be adequate.

During the conceptual design concrete and metal roof schemes were abandoned because they absorb too much heat. Fabric structure alternatives were studied in consultation with Horst Berger of Geiger Berger Associates whose fabric roof for the Biecentennial in Philadelphia had proven effective in improving comfort on hot days. PTFE coated glass fiber fabric reflects 70 % of the sun's heat, radiates out during the night, eliminates electric light because of its translucency.

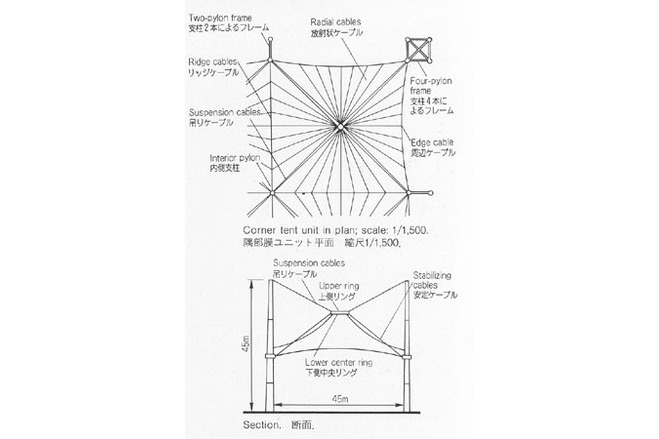

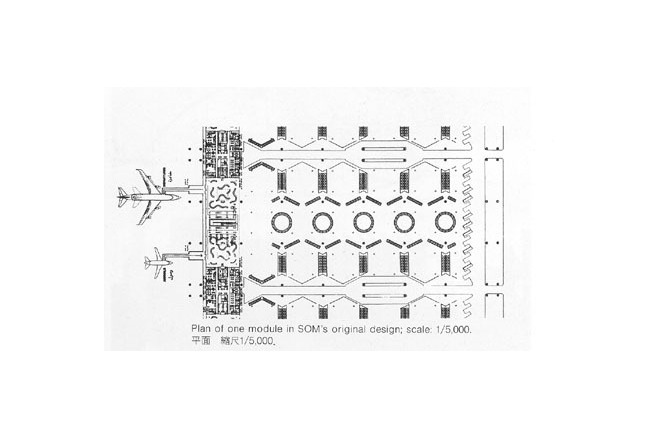

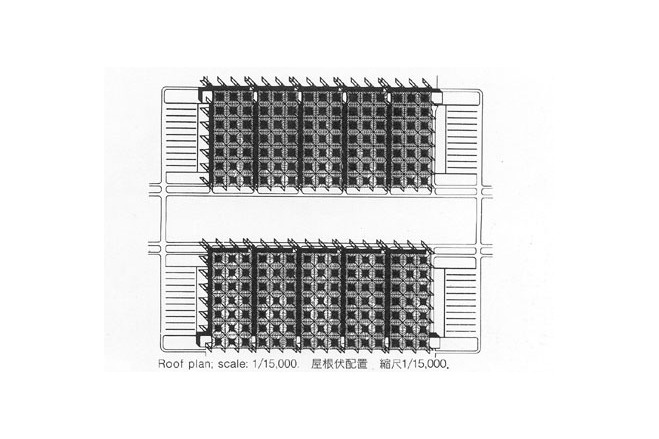

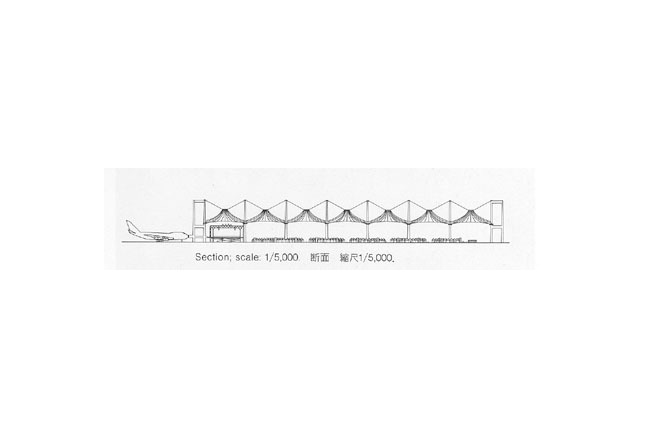

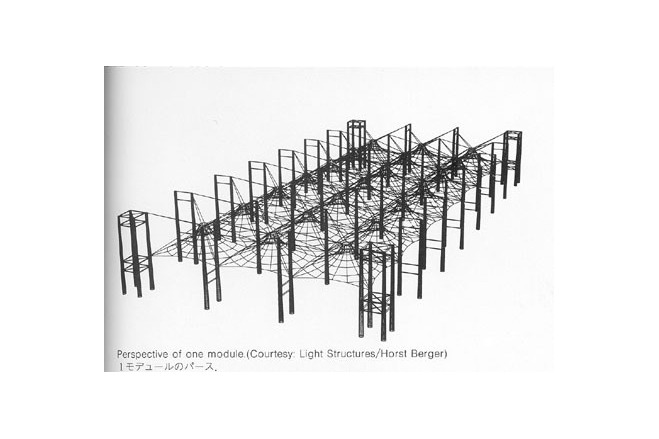

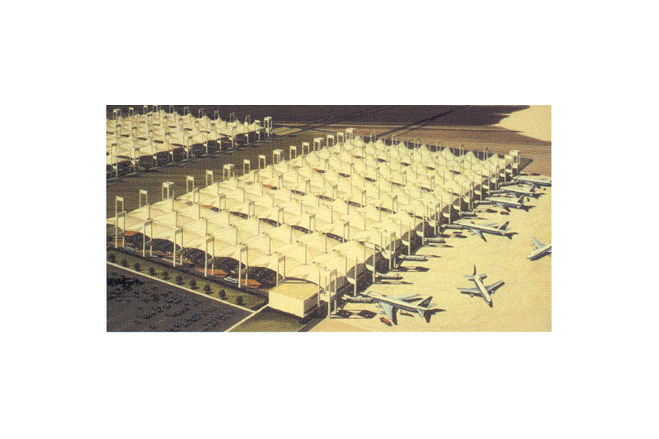

SOM chose a fabric structure concept which divides the building into 10 modules, each consisting of 21 tent units with a plan dimension of 45,75 x 45,75 m. each module covers 320 x 137m. Two groups of five modules each are arranged along two sides of a central access road. 20 gates for the planes are located at the opposite ends of the modules.

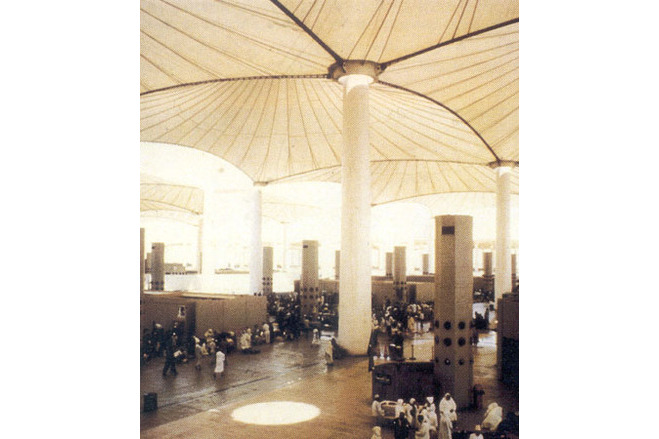

To keep the space below open, the structural concept by SOM's Fazlur Khan suspends the tent units from high masts which are located at the four corners of each tent. Interior supports consist of single columns. Along edges and corners two or four columns are combined into frames to resist the lateral forces. This arrangement of the support system gives the architecture of the world's largest roof its powerful image. Stepping from the heat of the desert sun into the shade of the Haj Terminal roof is similar to entering the pleasant atmosphere of a giant forest.

(Horst Berger, Light Structures/ Horst Berger, Prof. At CCNY)

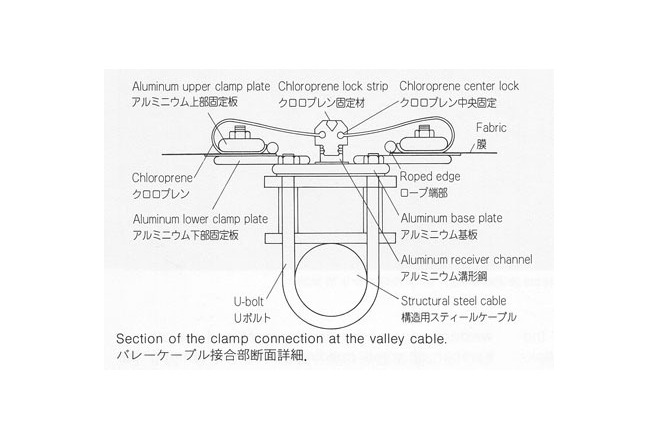

The detailed design of the Haj Terminal tensile roof was crried out by Geiger Berger Associates as consultants to Owens Corning Fiberglass in a design/construct contract. Horst Berger was principal-in-charge. This included formfinding of the membrane, sizing of components, detailling of connections, non-lineair analysis of the structure, and engineering of the erection process of this record size roof which covers the area of 12 football stadiums. Each of the 210 tent units was the largest fabric tensile structure the firm had designed in 1976. The firm's new mathematical tools had to be expanded. Interaction of elements in a very large structure - each of the two five module halves is 427 x 320 m - had to be considered. Complex but highly repetitive connectors had to be designed.

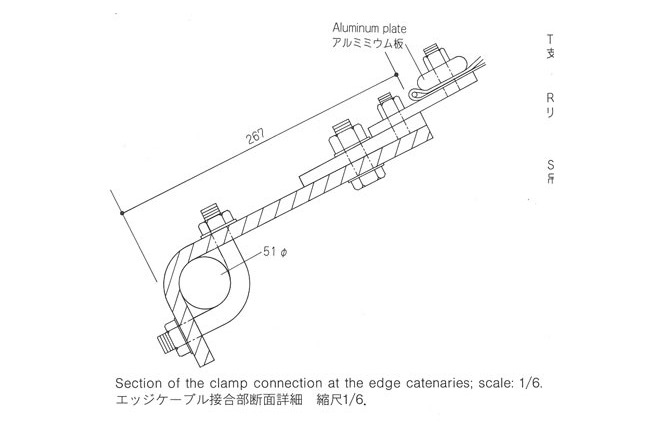

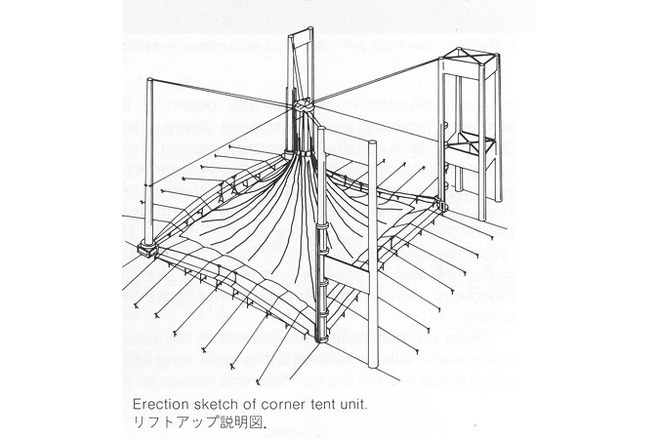

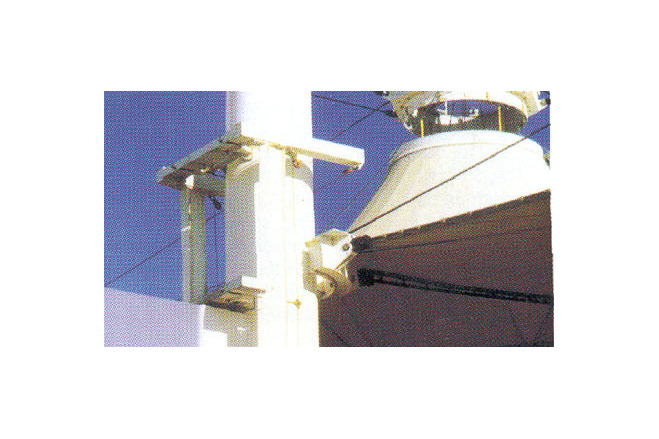

21 radial tent units form each module, each consisting of a fabric cone reinforced with 32 radial cables and bounded by edge catenaries and/or valley cables. At the top, fabric and radial cables are connected to the lower part of a two-part ring of 4,5 m diameter, allowing fabric and cables to be installed near the ground. The upper part of the ring was suspended from the four adjacent pylons. Winches on the upper ring part lifted all 21 units of a module simultaneously, electric gear jacks finishid the lift and stressed the system. Eight connector rods connect the two ring parts to each other.

The 46 m high pylons were fabricated in Japan by NKK and shipped to Jeddah on barges. Exterior pylons were connected into frames to resist lateral loads. During construction the free edge of each module acted as an exterior edge until the next module was installed. The effect of this construction process had to be included in the analysis and stressing of each module.

In its 15 year life this giant fabric structure has proven highly successful.

(Horst Berger, Light Structures/Horst Berger, Prof. At CCNY)

[Membrane Designs and Structures in the World, Kazuo Ishii, p200-202]

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Material Fabric/Foil

Fiberglass

-

Material coating

PTFE

Main dimensions and form

-

Covered surface (m2)

440000

-

Total length (m)

320

-

Total width (m)

137

-

Form single element

Anticlastic

Duration of use

-

Temporary or permanent structure

Temporary

-

Design lifespan in years

31-..

Involved companies

-

Architects

Skidmore Owings & Merrill

-

Engineers

Geiger Berger Associates

-

Contractors

Owens-Corning Fiberglas Corp.

Editor

-

Editor

Marijke M. Mollaert