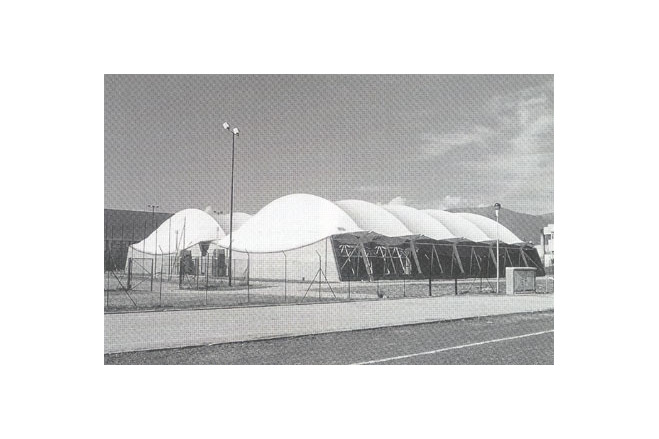

Covered Tennis Court in Gorle (Italy)

General information

-

Location address

Gorle

-

Location country

Italy

-

Name of the client/building owner

Commune di Gorle

-

Function of building

Sport

-

Degree of enclosure

Fully enclosed structure

-

Climatic zone

Mediterranean - mild winters, dry hot summers

-

Number of layers

mono-layer

Description

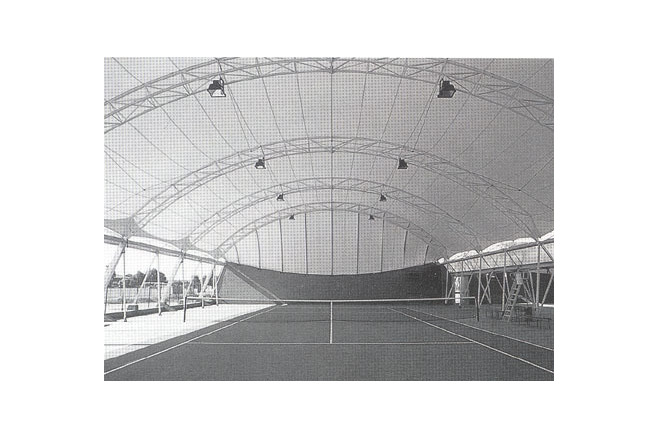

Covered tennis courts and tennis sheds exist in multitudes, but few of them are aesthetically pleasing, and hardly any of them is as beautiful as the one described here.

The design brief for a covered tennis court is clearly defined. The plan dimensions are given by the size of the playing fields together with the required moving space around them, similarly the height is given by the required space clearance in longitudinal and transverse direction. The end walls should be opaque in their lower parts to avoid glare. Natural lighting from above is desirable, and so is transverse ventilation during the hot season.

Design

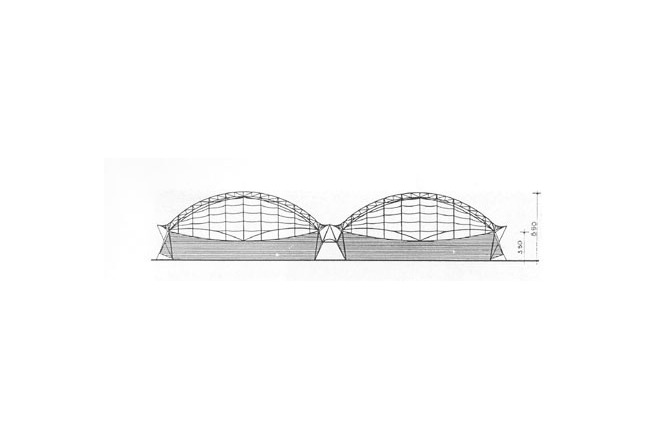

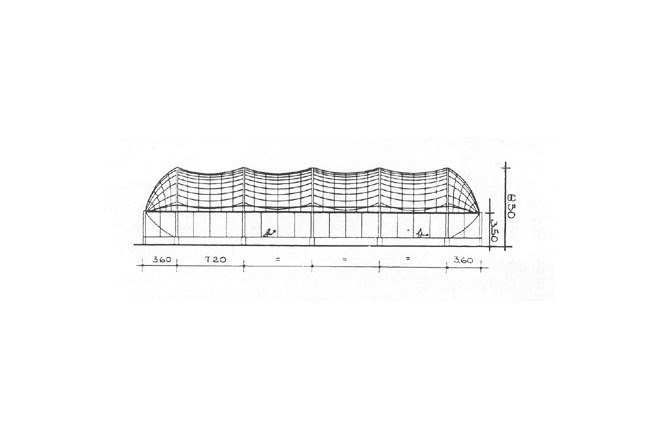

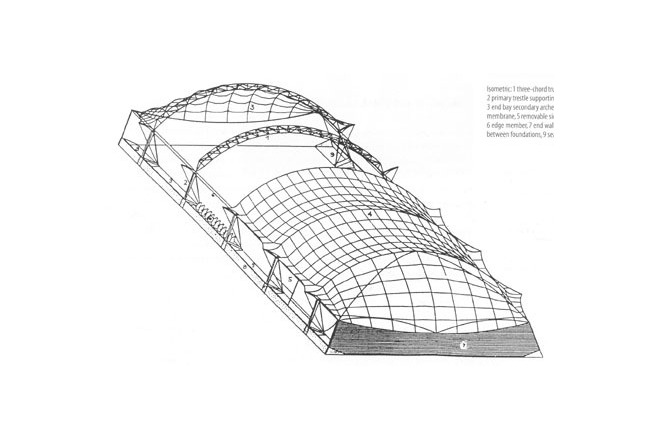

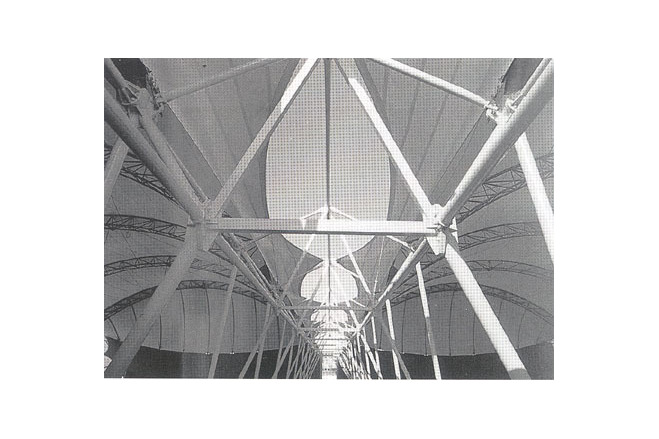

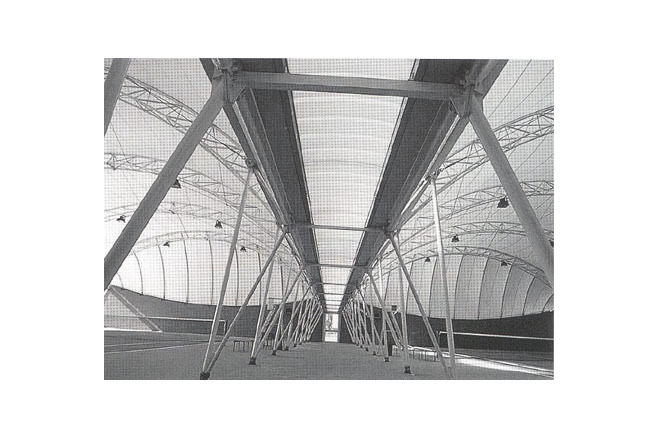

Two adjacent playing fields are covered each by an independent, self-supporting arch structure, consisting of parallel lattice arches. The arches are supported on steel trestles to achieve the necessary height over the playing field. The trestles along the central spine are connected to form a stiff bracing frame over a central access corridor. The space-enclosing element is a fabric membrane, together with a linear roof light made of curved and planar polycarbonate sheets over the central spine, which cover the upper portion of the central bracing frames. The roof membrane cantilevers along the long sides of the building by way of steel brackets, forming a continuous edge canopy, so that during the summer months the fabric side walls can be removed to aid transverse ventilation without the danger of rainwater entering the building. In the end bays the roof membrane is carried by tubular steel arches which are supported by a concrete wall with a curved upper edge.

Description of the environmental conditions

Dimensions

The covered plan area is 22 x 36 m for each playing field; the total floor area is 2 x 792 = 1584 m². The maximum building height is 8.5 m on the outside; the corresponding inside dimension at the net is 7.80 m. The height of the parabolic top of the end walls varies between 2.25 m at the centre and 3.5 m at the edge.

Structure

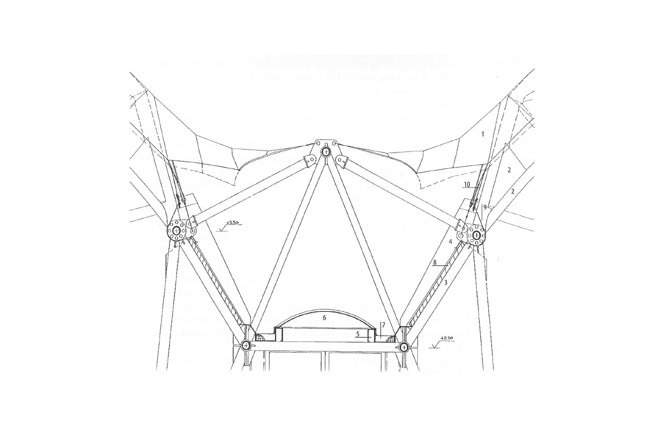

The structure consists of a self-supporting roof membrane supported by five two-pin three chord truss arches (top chord Ø 133 x 4 mm, bottom chords Ø 101.3 x 3.6 mm, diagonal web members Ø 76 x 3.2 mm). Five pairs of trestles at 7.2 m c/c carry the arches at a height of 3.5 m. The compression strut of the trestle has a cantilever bracket attached at its top, to which the edge of the roof membrane is connected. The strut member with a rectangular cross section is made up of welded steel plate and tapers according to the shape of the moment diagram. The associated tension member is made of steel pipe (CHS) with pin connections at top and bottom.

Between the primary trestles there are secondary CHS trestles (at 3.6 m c/c), to which the valley cables of the cable net, bracing the arches, is connected.

These planar trestles are arranged at a right angle to the side of the building, with a plane dimension of 2.0 m between tension and compression member, and are connected at the top by a horizontal edge member and braced in the end bays by a diagonal pipe bracing member. The trestles along the central spine form an A-frame made from steel tubes (Ø 88 x 3.2 mm ; Ø 76 x 3.2 mm and Ø 60 x 3 mm). For ease of erection it is assembled from five components.

In the end bays the membrane is supported by nine tubular steel arches, supported by the truss arch on one side and connected in pockets at the reinforced concrete end wall.

The roof membrane spans in transverse direction from arch to arch, vertical roof loads are carried into the arches; and the arch thrust is taken into the edge trestles and central A-frames. The external compression members and the inner ties are connected to reinforced concrete foundations. The cantilever brackets support the membrane corners and receive the edge cable forces. The roof was designed for a snow load of 0.6 kN/ m2.

Bracing

The building is braced in longitudinal direction by compression diagonals in the end bays together with a horizontal CHS collector member at the eaves. In transverse direction the building is braced by the arches and the supporting trestles together with reinforced concrete end walls. Perpendicular to their plane the arches are braced by a prestressed, three-dimensional cable system, consisting of five stabilising cables connecting the arches, and a prestressing cable parallel to the arches. This cable system is connected at five points along the arches and to eight secondary edge trestles. In the end bay the cables run across the last arch to be anchored at the top of the concrete end wall.

Membrane

The roof membrane is made of a PVC-coated polyester fabric Precontraint 1002 (Ferrari) with a strip tensile strength of 4.2/4.0 kN / 5 cm (warp/weft) and with spread of flame treatment. It has a translucency of approx. 15 %, which together with the polycarbonate roof light is sufficient for daylight illumination

[Soft Shells, Hans-Joachim Schock, p78, 80]

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Cable

-

Material Fabric/Foil

Polyester

-

Material coating

PVC

Main dimensions and form

-

Covered surface (m2)

1584

-

Total length (m)

22

-

Total width (m)

36

Duration of use

-

Temporary or permanent structure

Temporary

-

Convertible or mobile

Convertible

-

Design lifespan in years

00-05

Involved companies

-

Architects

Studio Tensoforma

-

Contractors

Tensoforma Trading S.R.L

Editor

-

Editor

Marijke M. Mollaert