Velodrome

General information

-

Home page

www.form-TL.de

-

Location address

Abuja

-

Location country

Niger;nigeria

-

Name of the client/building owner

Federal Capital City Abuja

-

Function of building

Sport

-

Climatic zone

Arid - dry and hot all year

-

Type of application of the membrane

covering

Description

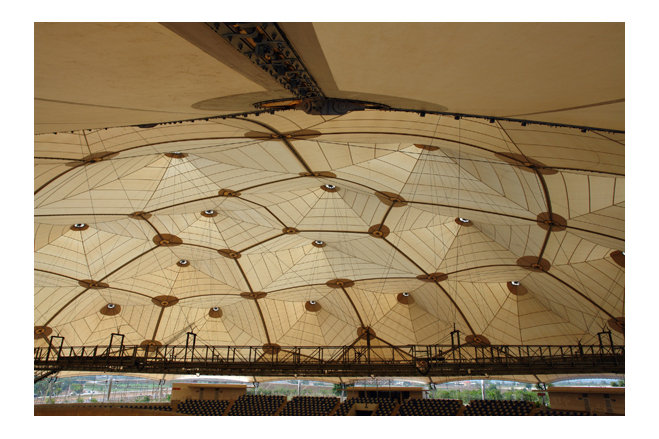

For the All African Games in 2003, a large sports complex was built. Part of this sports complex was a Velodrome with a 250 m cycling track. The Velodrome has been covered with a PTFE/glass membrane, supported by 8 main masts, and 16 perimeter columns.

At the last day of the All African Games a massive thunderstorm destroyed the complete membrane. The main masts were still in place, and had not been damaged. It was then decided to rebuild the roof with the same appearance, but with a more redundant membrane system.

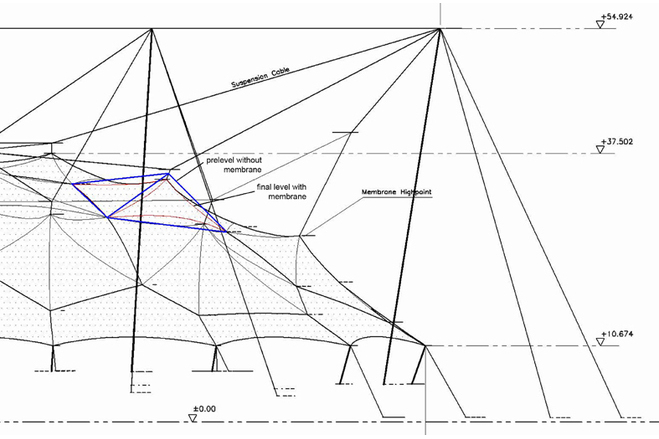

Main goal of the redesign was to avoid any modification on the main masts, and ideally no replacement of the main suspension cables.

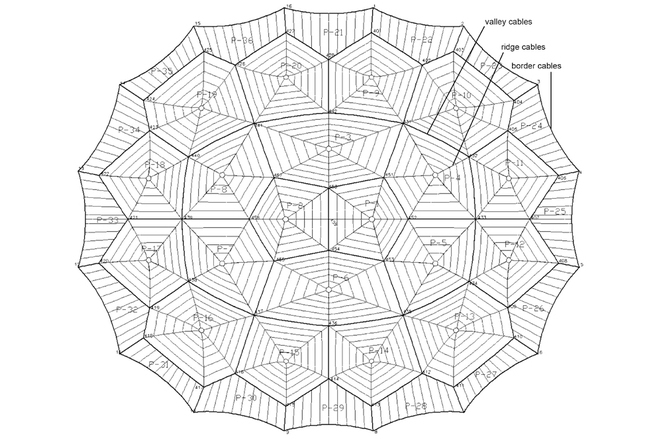

We started our design with the evaluation of different types of large scale cable nets, to achieve a system with a comparable load bearing behaviour. We ended up with a pentagon and hexagon pattern, forming a shape similar to the previous membrane roof, and with a comparable geometric stiffness.

Each pentagon or hexagon is supported by ridge cables underneath the membrane, tensioned in one centre point.

For the installation, a pre-level was defined, up to which the cable structure had to be tensioned, to achieve a fully stable structure without the membrane.

Panel after panel was then installed. In each panel the membrane cables were released from the “pre-level”, and the cables were hanging loose. Along the perimeter, all clamping plates are connected with U-plates to the valley cables, and with a circular clamping around the nodes.

When the membrane bay is attached along its whole perimeter, the membrane is tensioned at the central node. This tensioning is done up to a “soft” tensioned stage, and then finally prestressed when all panels are installed.

After the final tensioning, all valley cables were covered with a closure flap, and the gutter was welded on site.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Cable

-

Material coating

PTFE

Main dimensions and form

-

Covered surface (m2)

10649

Duration of use

-

Temporary or permanent structure

Permanent

Involved companies

Editor

-

Editor

Evi Corne