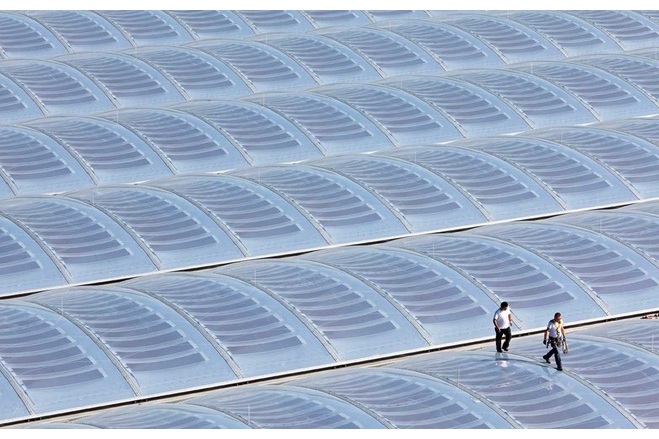

Carport roof cover of three-layered ETFE film cushions with integrated flexible photovoltaic cells

General information

-

Location address

Munich

-

Location country

Germany

-

Year of construction

2011

-

Name of the client/building owner

City of Munich – Building Division and Abfallwirtschaftsbetrieb® AWM München

-

Function of building

Vehicle services

-

Degree of enclosure

Open structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

multi-layer

-

Type of application of the membrane

covering

-

Primary function of the tensile structure

- Daylight gains

- Rain protection

Description

The roof area is made from 220 air-supported cushions. The 220 air cushions covering the roof elements are made of ETFE film. This material is very translucent and resistant to the influences of the weather. Each cushion is made of three layers of ETFE film. As is customary in membrane constructions, the layers are termed upper layer UL, middle layer ML and inner layer IL.

The lower film layer is printed to reduce the light transmitted through the film cushions onto the carport deck. There are 12 photovoltaic modules fixed to the middle layer of each cushion by means of mechanical connectors, some of which can be moved, so that the modules are not subjected to any bending, tensile or shearing forces, even not in the event of heavy snow loads. As with bridge supports, for example, one of the PV module attachments is always without a longitudinal hole, in other words it is in a permanently fixed position, preventing the PV module from "floating freely". The middle layer is mechanically pre-stressed to prevent creasing and is without load in the operating state, since the large ventilation openings in it lead to the same inner pressure above and below the middle layer. To allow any faulty modules to be able to be replaced easily even in the long term, the upper film layer was fixed separately from the other two heat-sealed film layers in the double-welt clamping profile. This layer can be opened separately and basically works like a service cover.

The load cases of the pre-tensioned ETFE films, intrinsic weight, snow, wind and change in temperature were considered in the calculation of the roof structure. Whereas the static calculation of the primary load-bearing structure was carried out using a standard calculation program for space bar frames, the calculation software using the force-density method, which has been especially developed for architecture membranes, was used for the final design, static calculation and cutting pattern layout specification of the ETFE film.

Pneumatic systems become tensioned, pre-stressed structures due to the air overpressure at the inside. The pre-stress in the upper and lower membrane is the result of the difference in pressure between the inside of the cushions and atmospheric pressure. It also depends on the radius of the corresponding membrane layer. The overpressure in the cushion is maintained using blowers. The membrane layers are always tensioned under load and are thus kept stable. Cushions are usually designed with two or three layers, depending on the structural-physical requirements.

The design of the air supply to the film cushions through blower units primarily depends on the magnitude of the defined inner pressure, the number of cushions and the size of the total area. An air dryer is included upstream of the blower. The supply air is dried to prevent condensation forming in the film cushions.

The air supply is connected to the lower cushion chamber. Air is exchanged between the upper and lower cushion chambers via overflow openings in the middle film layer (two rows of 12 circular holes with a diameter of 90mm at the edge of the middle layer of the cushion and one row of 12 holes at the peak of the middle layer). The air escapes via the air outlet. The flushing rate of the cushion volume (air exchange of the cushion volume was estimated at 3.000m³/24h at planning) was specified by the building engineer to 4.500m³/24h, in other words 1,5 times per day. The prescribed flushing rate is set using the cross-section area of the air outlet. In the nominal case, the support air pressure inside the cushion is 300 Pascal compared with the atmosphere. In the event of snowfall, this pressure can be increased to 600 Pascal. If the snow load exceeds 0.6 kN/m², the cushion is compressed in a controlled way. In this case, the upper and lower film layers bear the load together.

The geometric form of the film cushions chosen means that no water pockets will occur even if the blower fails during a period of rainfall. Pockets of snow can form towards the lower edge in the event of drifting snow. However, the local additional loads do not endanger the structural safety and do not lead to any significant deformation. The stability of the cushion roof structure is not dependent on support air supply. Nevertheless, it was decided to make this supply particularly reliable (Fig. 6). Three blower units supply one third of the roof area each. Each station has two redundantly wired blower motors which alternate on a weekly basis and automatically replace each other if one of the blowers should fail. The air supply is connected to an emergency power supply and a remote warning system. Each cushion assembly with corresponding blower is integrated in a separate ring air pipe. All three ring air systems are separated from each another by valves which enable the area affected by blower station failure to be supplied by a neighbouring station. In addition, an air pipe system with high density class and non-return valves was chosen for the blower stations, making the whole system extremely airtight.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Foil

-

Type (code)

ETFE foil Nowoflon ET-6235

Main dimensions and form

-

Covered surface (m2)

8000

Duration of use

-

Temporary or permanent structure

Permanent

-

Design lifespan in years

31-..

Involved companies

-

Architects

Ackermann und Partner Architekten BDA

-

Engineers

Ackermann Ingenieure

-

Contractors

Taiyo Europe

-

Suppliers

NOWOFOL

Editor

-

Editor

Evi Corne