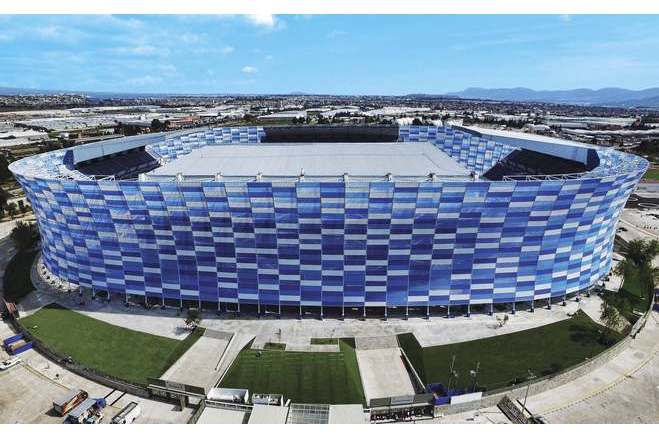

Estadio Cuauhtémoc

General information

-

Location address

Puebla

-

Location country

Mexico

-

Year of construction

2015

-

Name of the client/building owner

City of Puebla

-

Function of building

Stadia

-

Climatic zone

Tropical - hot and wet all year

-

Number of layers

mono-layer

-

Type of application of the membrane

covering

Description

The sports complex, built in 1967, had already hosted suspense-packed competitions at the Summer Olympic Games in 1968 as well as being the venue for the FIFA World Cup in 1970 and 1986. The stadium was completely modernized in the years 2014/2015 and furnished with the first ETFE façade in Mexico by Dünn Lightweight Architecture.

The façade seems extremely lightweight in its curved shaped and incorporates pre-Columbian design elements with its mosaic character. It consists of 124 vertical segments, about 40m in height. A total of 5.952 ETFE film sections in the three shades were welded to one another for the segments.

In the daytime the club colors of blue and white as well as the transparent sections continue to be visible. By night the film sections are illuminated in various colors by LED lights.

Especially important in the hot and humid climate: In the production of films made of 3M Dyneon ETFE no plasticizers are required, which evaporate over time and thus could promote algae or fungal growth. ETFE films are so smooth that rain showers are sufficient to clean the façade to the greatest possible extent. They are so resistant to other chemicals that they are also able to withstand environmental influences such as exhaust emissions for decades. Originally, parts of the façade of the stadium in Puebla were made of glass panels in various colors. Dünn Lightweight Architecture chose to design the complete façade with ETFE film instead. One significant advantage: The weight per unit area of ETFE is around 95% lower than that of glass. As a result, stress analyse were able to build the supporting structure in a much lighter way. Instead of the 2.500tons of steel required for a glass construction, 1.000tons are sufficient for the ETFE façade, a saving of 60 percent.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Foil

-

Material Fabric/Foil

NOWOFLON ET 6235Z

Main dimensions and form

-

Covered surface (m2)

98.425

-

Form single element

Flat appearance

Duration of use

-

Temporary or permanent structure

Permanent

Involved companies

-

Architects

Dünn Lightweight Architecture

-

Engineers

Dünn Lightweight Architecture

-

Suppliers

NOWOFOL

Editor

-

Editor

Evi Corne