Fish and Fruit Market of Ananindeua

General information

-

Location address

Ananindeua

-

Location country

Brazil

-

Name of the client/building owner

Ananindeua City-Hall

-

Function of building

Shops and stores

-

Degree of enclosure

Open structure

-

Number of layers

multi-layer

-

Type of application of the membrane

covering

Description

Introduction

Ananindeua is a small town in the suburbs of Belem, capital of the state of Para.

One of the most important sources of income for the community of Ananindeua is its abundant commerce of fish and fruit, produced by the local fishermen and farmers.

As a result of the ever expanding market, the existing site and its surroundings had turned into one of the busiest places in town. The infrastructure had become unsuitable and insufficient, and the search for a better place was urgent.

In 2005, architects Jose M. Bassalo and Flavio C. Nascimento invited Mr. Paulo Barroso, a structural engineer, specialized in membrane and steel structures, to join the team to develop a project for the new market place, including a roof structure.

The new market place

The new market place, inaugurated in November 2006, covers 3250m2 of an old and unused public space. This particular location was chosen mostly because it provided better and more convenient transit and transportation facilities. The new market site could also benefit from other important advantages already present, like a sewer system, and the supply of electricity and drinking water.

The steel framework and the membrane roof

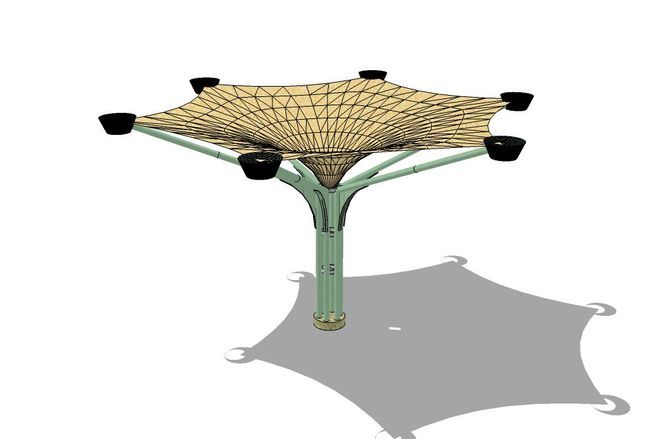

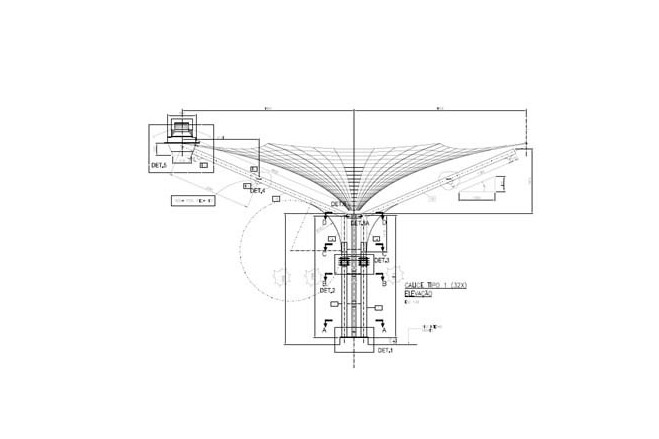

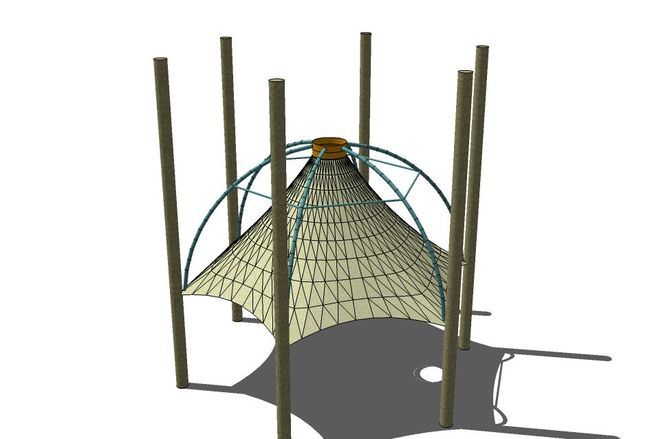

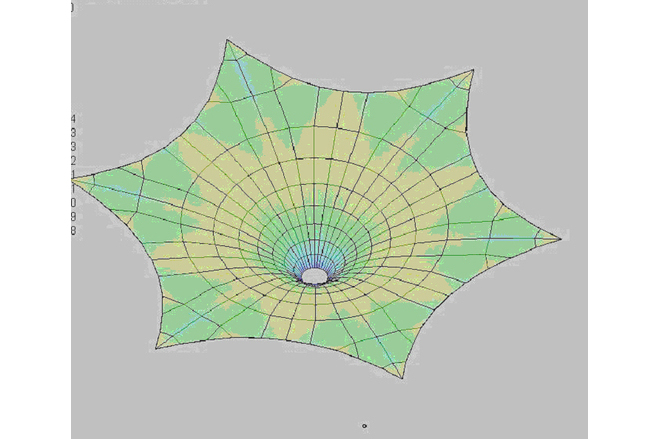

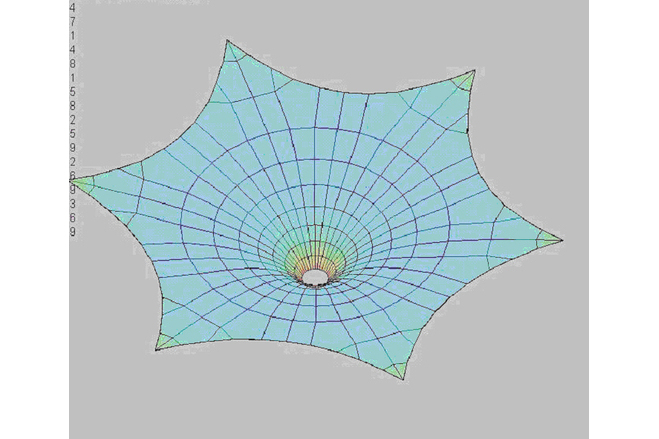

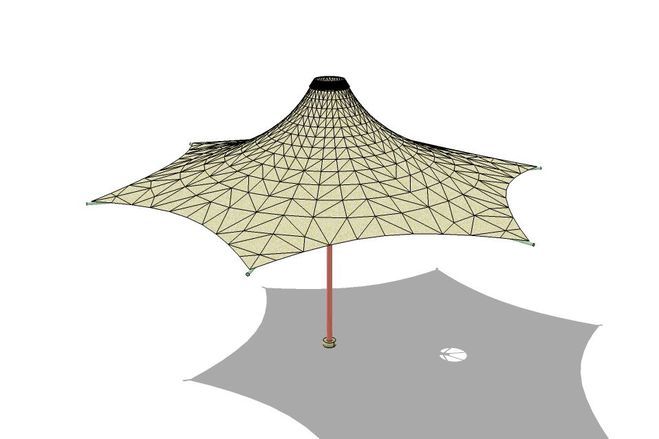

The membrane roof was conceived as a combination of three main structural elements: 42 hexagonal chalices (inverted umbrellas) with a diameter of 9.6m, 4 hexagonal umbrellas with a diameter of 16m, and 2 main conical tents – hexagonal, and with a 16m diameter as well.

The membrane roof elements are supported by a very rigid tubular steel space frame, fixed on base by anchor bolts, and their edges clamped by circular steel rings. This entire structural system behaves as a whole, thus providing exceptional stiffness to withstand pre-tension stresses and all service loads.

The corners of the chalices, umbrellas, and cone tents have been designed with tensioning devices, in order to be able to provide all respective membranes with the appropriate tension. Membrane edges are sustained by threaded rods, protected by pockets, and fixed at the ends by nuts. This would allow for additional tension regulation, and for stretching membrane borders as well.

Rain water is collected by special steel plated funnels at the centre of each chalice. Besides the steel funnel, additional regulation and tensioning points have been provided. Eventually, each membrane structure element has 6 peripheral sets of restraints, and one internal.

For better internal ventilation and a dynamical air and heat exchange, each inner connecting ring was provided with an air exhauster.

To seal all gaps between the hexagonal edges of the chalices, an additional skylight covering was necessary, in the shape of semi-elliptical eyes. By choosing an opaque white textile, a special effect could be achieved – especially under artificial lighting.

Finishing

Because of the aggressive hot and damp Brazilian weather, with heavy rains almost every day, all metalwork had to be protected against corrosion by hot dip galvanization. This will improve the weather resistance capacity of all steel parts to match the membrane’s life cycle.

Loads and stresses

Since there are no earthquakes, snow loads, hurricanes, etc. in this region, structural components were designed for the following loads and stresses:

Framework self weight: 0.2 kN/m2

Live loading: 0.25 kN/m2

Wind speed 108 km/h – average pressure or suction: 0.5 kN/m2

Membrane self weight and fittings: 0.01 kN/m2

Membrane rupture stresses – Type I, tensile strength: 60 kN/m

Maximal membrane pre-stress: 7.5 kN/m

Maximal membrane wind loads + pre-stress: 12 to 15 kN/m

Steel framework stresses according to Brazilian regulations NBR8800 and AISC-ASD 91

Transport and on site assembly

Transport and on site assembling was made easy by deciding on the right sizes and overall dimen¬sions for each structural element in the design phase. Due to the site’s topology and maximum highs to be reached, only small han¬dling and rising equipment were necessary.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Type (code)

Polyester/PVC

-

Material Fabric/Foil

Polyester

-

Material coating

PVC

Main dimensions and form

-

Covered surface (m2)

3200

-

Form single element

Anticlastic

Duration of use

-

Temporary or permanent structure

Permanent

Involved companies

-

Engineers

TECHNICA Consultoria & Projetos Ind. Ltda. (Paulo A.B. Barroso)

-

Contractors

TECNO STAFF ENGENHARIA E ESTRUTURAS LTDA

-

Suppliers

SERGE FERRARI

Mehler Texnologies

Editor

-

Editor

Marijke M. Mollaert