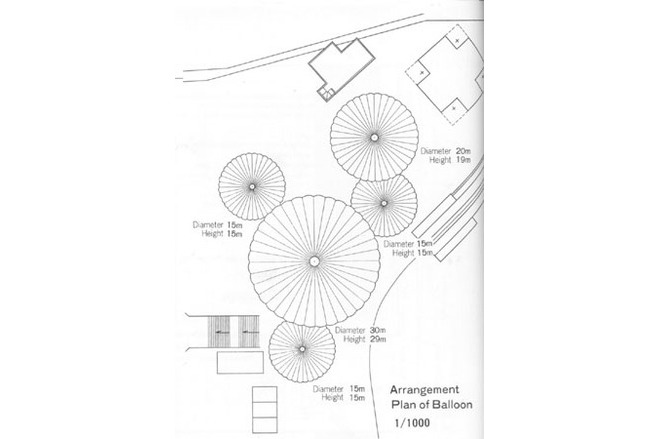

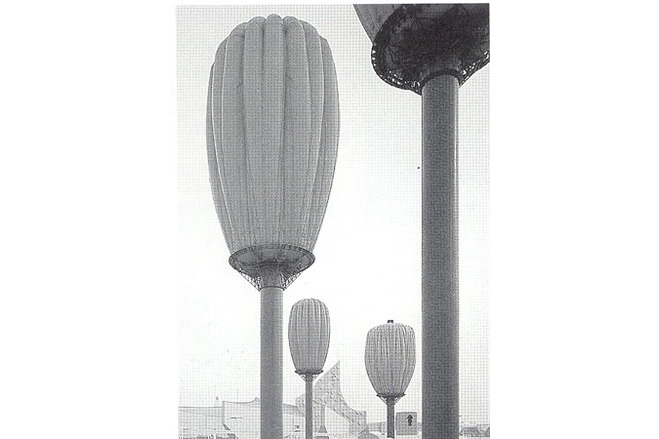

Expo 1970 (Osaka): Mush-balloon

General information

-

Location address

Osaka

-

Location country

Japan

-

Name of the client/building owner

Expo '70 Association

-

Function of building

Public spaces

-

Climatic zone

Temperate - cold winters and mild summers

Description

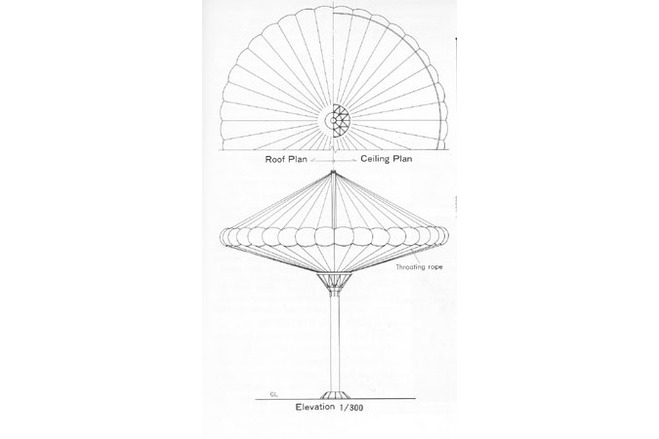

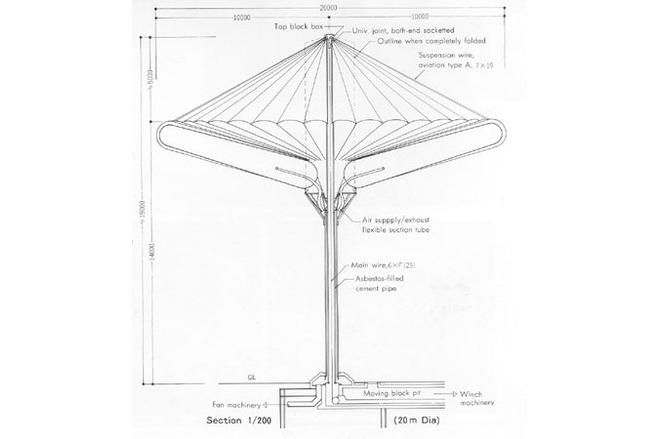

Structural Scheme

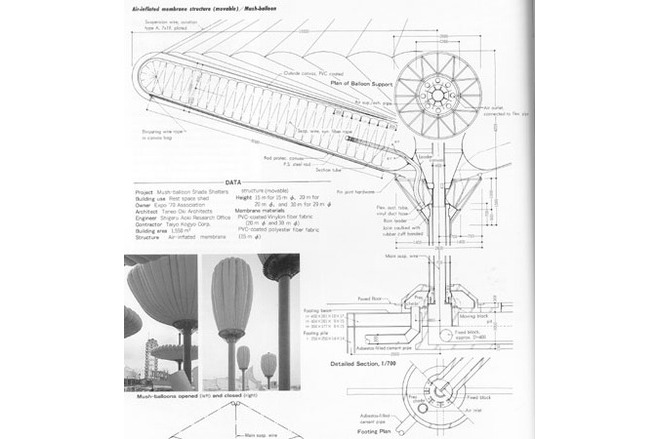

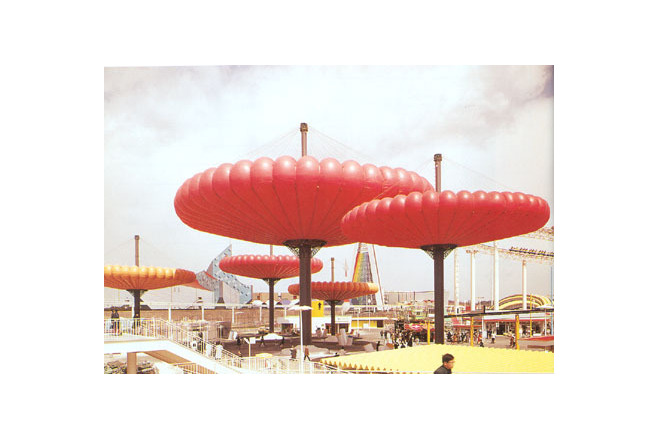

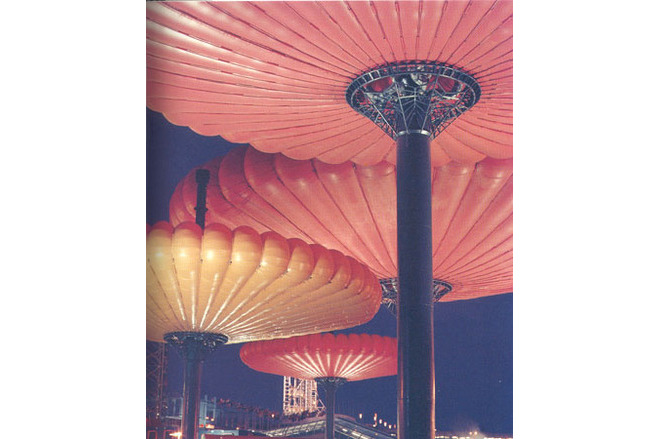

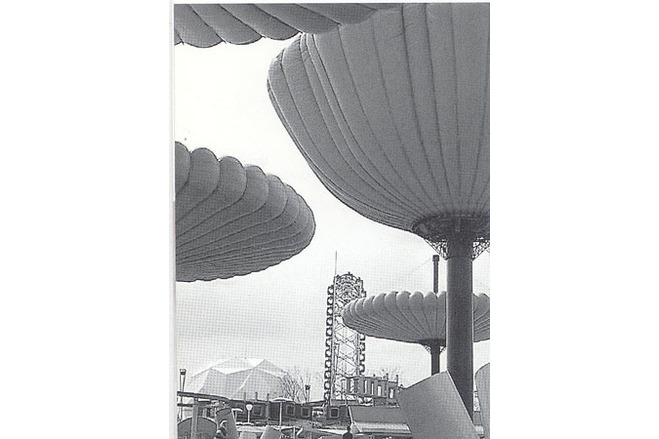

The Mushballon, an inverted cone shaped balloon, was suspended by 45 wire ropes that passed from the top of a pole through the center of the balloon. The balloon was made of an upper fabric and a lower fabric. These were braced by inner ropes, creating an airtight envelope. Both upper and lower fabrics were braced by ropes, sculpturing a repeating surface of slender cylinders which radiated from the center pole. The curvatures of the cylinders in respective canvases differed from each other.

The two different curvatures of the upper and lower planes produced a flattened and outward extending effect in the expanded balloon. This also produced a greater tension to the suspension ropes. The relation is comparable to incorparating piano wire rods or steel cables under tension in concrete.

The design was constructed to withstand a wind velocity of 15 m/sec in its opened state and 60 m/sec in a closed state. The balloon's internal air pressure was 150 mm Aq in its opened state, and between 100 and 50 mm Aq during the course of opening or closing.

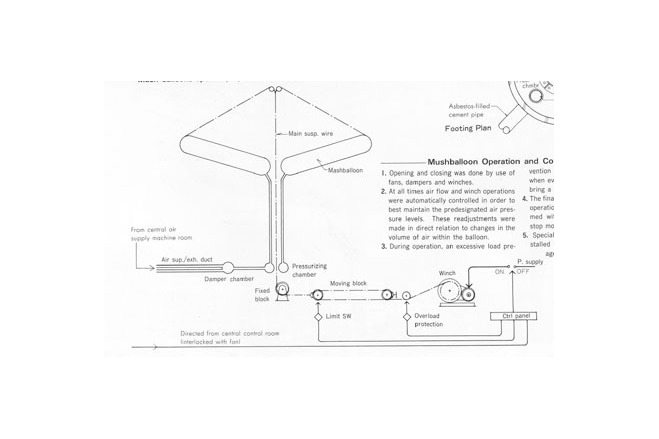

Opening and Closing Operation

The operation of opening and closing this structure was performed in simultaneous actions of blowing air into or venting it out of the balloon while winding or unwinding the suspension cords.

During the course of this procedure, it was inevitable to have an imbalance between the dimishing expansion force of the balloon and the restraining force of the cables, thereby causing a lowering of the rigidity of the balloon. In this state the Mushballoon was more vulnarable to horizontal or upward lifting wind loads.

The most appropriate control was to blow air in or vent it out, adjusting the pressure continually, accurately and keeping it within a range that would cause no deformation at all. Through this process the balloon could withstand winds and excesses of allowable stress from the suspension cables during the opening and closing operations.

There were two systems used during opening and closing procedures : One was an automatically controlled air pressure and ventilation system, and the other was a wire rope winding system. The latter system automatically controlled the winding and unwinding of tension chords to avoid excessive loads to the structure. These two independent systems were monitored by a central control board and its computer software.

[Membrane Structures in Japan, Kazuo Ishii, p100-101]

Description of the environmental conditions

Wind-bracing Disosition

In a typhoon recipient region such as Japan's, serious attention must be given to fabric structures made of light weight materials in regard to their anti-typhoon measures. There are three optional safety methods. The first is to suppress fluttering by introducing sufficient tensile force to the fabric surfaces to increase the tension of the fabric until it reaches a state of rigidity. Generally this method is applied to single-layerd membrane structures where the problem can be solved with the initial tensile force of the membrane combined with the higher interior air pressure produced by inflating the membrane.

A second successful method is to set up reinforcing materials (such as tay cable, reinforcing poles or other structural sections) when a typhoon is approaching .

The last method is to disassemble or compactly fold the fabric, thus avoiding damaging high wind pressures from powerful typhoons.

Similair to the folding and closing umbrella under heavy wind condition, the Mushballoon undergoes the third alternative. When typhoons are approaching its inverted cone-shaped balloon is closed to minmize its surface area.

[Membrane Structures in Japan, Kazuo Ishii, p100]

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Material Fabric/Foil

Vinylon

-

Material coating

PVC

Main dimensions and form

-

Covered surface (m2)

1550

-

Total length (m)

20

-

Total width (m)

20

Duration of use

-

Temporary or permanent structure

Temporary

-

Convertible or mobile

Mobile

-

Design lifespan in years

00-05

Involved companies

-

Architects

Tanero Oki Architects

-

Engineers

Shigeru Aoki Research Office

-

Contractors

Editor

-

Editor

Marijke M. Mollaert