Elspe Grandstand Canopy

General information

-

Location address

Lennestadt-Elspe

-

Location country

Germany

-

Year of construction

1978

-

Year of dismantling

2015

-

Year of replacement of membrane

2015

-

Short description of the replacement or dismantling

Mehler Texnologies developed an individual membrane as close as possible to the original material from 1978, bearing the same green colour.

-

Name of the client/building owner

Elspe Festival GmbH

-

Function of building

Entertainment & recreation

-

Degree of enclosure

Open structure

-

Climatic zone

Temperate - cold winters and mild summers

-

Number of layers

mono-layer

-

Primary function of the tensile structure

- Rain protection

- Sun protection

Description

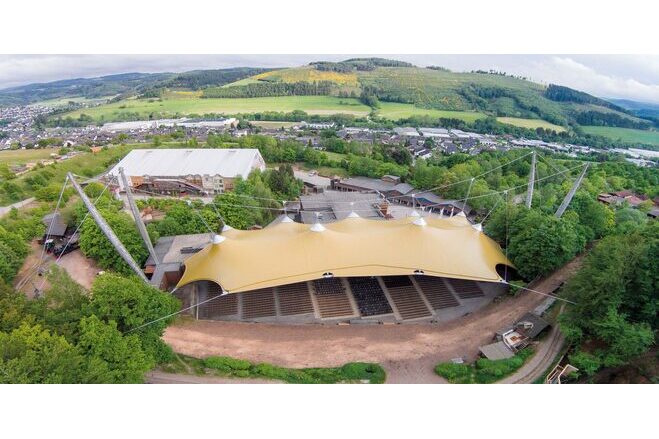

Since 1st July 1978 the 4400 spectators of the famous Karl May festival have been sitting under a fabric roof. After the Olympic structure in Munich the membrane roof in Elspe was one of the biggest, winter proof covers in Europe.

Structure

Four masts with a diameter of up to 1,50m hold two 72mm thick steel cables with a length of more than 100m. The 127m long fringe of the membrane is stabilized by a polygonal rope. The membrane is up to 77m long and 32 – 40m wide. It is fixed to 9 knots of the steel cable system and beside of 8 points at the fringe to a 65m long concrete wall.

Mehler Texnologies developed an individual membrane as close as possible to the original material from 1978, bearing the same green colour. The experts of Koch Membranes say: “Altogether the classical membrane roof in Elspe is a good example for maintaining and developing a sustainable construction. A well done fabric construction is more than ever a fast, reliable and economic way of construction with a high degree of publicity.”

For Mehler Texnologies the supply of the new fabric was an opportunity in two ways: on the one hand the dismounted fabric gave an excellent proof under real life conditions. Better than any artificial weathering tests this makes clear that the fabric material lasts 37 years and more – even under heavy snow loads during winter time which are very common in the Sauerland region where the festival tent is located.

Continuous on site tests over the past years had already shown that the fabric was not in danger of coming down. Tensile strength was still considerably high and the fabric would certainly have lasted even another dozen years. In the end it was a decision for optical reasons: the festival company wanted to have a bright new colour impression. It’s clear enough that they made a material decision on save grounds: of course they wanted to use the same material that had shown an outstanding performance over the last 37 years. Given that today’s material science is even farther in terms of choosing the right chemicals for a long lasting and sustainable coating, the actual project might be charged off even more easily.

Apart from having loads of testing material of a 37 year old membrane, Mehler Texnologies was able to provide the new material which promises an even better performance.

Description of the environmental conditions

Material of the cover

-

Cable-net/Fabric/Hybrid/Foil

Fabric

-

Material Fabric/Foil

Valmex Mehatop F Type V

Main dimensions and form

-

Covered surface (m2)

2600

-

Total length (m)

77

-

Total width (m)

40

Duration of use

-

Temporary or permanent structure

Permanent

-

Design lifespan in years

31-..

Involved companies

-

Engineers

Teschner Ingenieure

-

Contractors

Koch Membranen

-

Suppliers

Mehler Texnologies

-

Other companies

Montageservice GmbH

Editor

-

Editor

Evi Corne